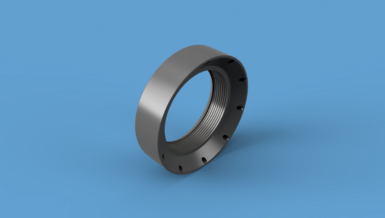

The design principle remains unchanged since day one; a unique external cutting (knife) system at the inlet that stops the Landia Chopper Pump from becoming blocked.

Originally created to chop straw in liquid animal manure that often causes stoppages and problems, the Landia Chopper Pump has since been installed worldwide – typically in those hard-to-handle applications where solids bring less sturdier pumps to a halt.

One of those very successful overseas installations has been for theaeration and wastewater system at a major poultry processor in Saudi Arabia. With the addition of a venturi nozzle, the Landia Chopper Pump becomes the AirJet aerator – serving an effluent treatment plant utilising MBR technology that treats wastewater from the poultry and rendering plants (c. 6,000m3/day). Made with cast iron casings, plus stainless-steel impellers and shafts, the AirJets keep wastewater aerated and mixed in two 800m3 balance tanks prior to Dissolved Air Flotation (DAF). In the two 130m3 DAF sludge tanks, AirJets keep the tanks’ contents fresh and homogenised prior to further treatment by a tricanter centrifuge.

AirJets are also utilised for two 150m3 biological sludge tanks, aerating and mixing to provide homogenous composition to sludge dewatering equipment. Furthermore, AirJets are also installed in anoxic tanks for mixing purposes, as well as in the sewage treatment plant.

The upgrade for this processor in Saudi has been managed by MSA Environmental, a leading independent environmental consultancy based in Wiltshire that operates within the food, drink and dairy sectors.

‘Robust and reliable’

Jerad O’Pray, Director at MSA Environmental, commented: “Not for the first time, the Landia Chopper Pump (here in the form of its AirJet model) has delivered very good performance, as well being extremely robust and reliable. To suit the size of the large balance tanks (2 x 800m3) at the poultry processor, we specified 18.5 kW AirJets as part of our design, whilst 7.5kW motors were best suited elsewhere throughout the plant”.

He added: “With our detailed engineering and process design experience we always look to provide our clients with the best possible solutions for the long-term. Landia equipment is a proven piece of kit that we have no hesitation in specifying. Importantly, we always get good back-up from Landia too. They are always keen to hear that their Chopper Pumps are working well and that the customer is happy”.

He continued: “We have also used these units on overseas projects in hot climates to handle aeration, anoxic tanks and sewage. There have been no problems, despite ambient temperatures that are consistently above 40 deg C. The AirJets also help reduce odour issues by keeping the tanks fresh during the near 24/7 operation”.

Much closer to home in Cornwall, Landia AirJets were also introduced during the upgrade of Dairy Crest’s wastewater treatment process in Davidstow, home to the much-loved cheddar.

Initially, four stainless steel AirJets were installed in balance tanks that required thorough mixing.

‘Long lasting equipment with low maintenance’

Simon Merchant, Manager for the Wastewater Treatment Plant (WwTP) said:

“We first rented a submersible Landia AirJet to put it through its paces and help minimise odour potential in our balancing tank. It proved itself for being robust, reliable and effective. We needed top quality, long lasting equipment with low maintenance. Some major modifications to our balance tank were undertaken, which included the addition of externally-mounted Landia AirJet units. These have been operational for four months, and the early signs are very positive with improved dissolved oxygen levels, reduced H2S levels – and much lower noise levels. In addition, they have proved to be very reliable so far”.

In this remarkable 70th anniversary year of the Landia Chopper Pump, its staying power has also been recognised by Cheshire-based FLI CAP Technology, who design and deliver a comprehensive range of process technologies for wastewater treatment.

‘Cost-effective process’

External 11kW Landia AirJets have recently been specified by FLI CAP Technology for two balance tanks (1150m3 and 1800m3) as part of an upgrade to a food factory’s effluent plant. For two rectangular tanks (both 200m3), submersible units from Landia will provide mixing. These 4kW 1000rpm mixers are ideal for smaller tanks.

John Hampson, Director at FLI CAP Technology said: “We are not tied to particular makes of equipment or systems, so for the many turnkey projects we work on, we bring the most suitable, cost-effective process to our customers for the long term. For their reliability, performance and longevity, we have always found that pumps, mixers and aerators from Landia work extremely well”.