Ensuring even flow from pump station to wastewater treatment plant is one of the major operations at EKJH (Etelä-Karjalan Jätehuolto Oy) site. EKJH is a waste management company handling waste from 9 municipalities. Its site is so big that personnel uses cars to drive from one end to the other. The pump station is located in a separate building and houses eight pumps placed above and below the ground level. Some of them are internal transfer pumps and the others are pumping wastewater towards Lappeenranta wastewater facility. The station has in-built automation system which ensures even flow of wastewater and collects data for environmental reports. When the previous system broke down, EKJH found themselves in trouble. Pumps were still working but their operation could only be checked in person. Furthermore, data had to be collected manually, which required a lot of extra work and time.

EKJH had to find a replacement for broken automation system.

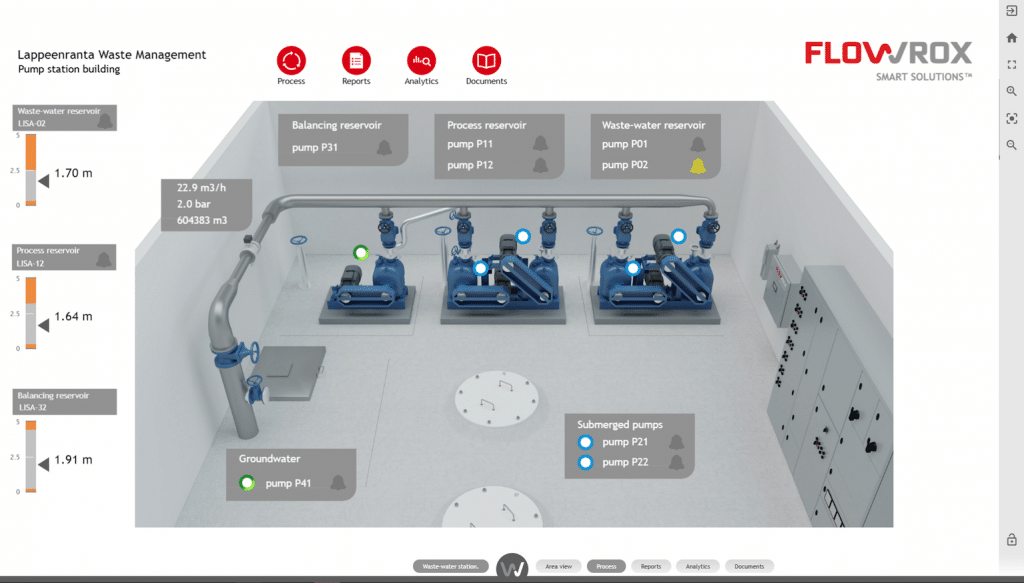

After examining multiple offers, EKJH chose Flowrox Smart SolutionsTM. Solution included new automation hardware, on-site installation, MalibuTM portal and end-user training. MalibuTM is a user interface custom made for each process. It is an exact model of the real pump station shown online. You can access and monitor your system operations through computer, tablet or smart phone. MalibuTM portal is user-friendly and makes it easy to navigate, manage and analyze processes.

MalibuTM portal is user-friendly and easy to navigate, manage and analyze processes.

Flowrox Offers Excellent Service

Flowrox’s goal is to provide complete solutions.

“We chose Flowrox because they offered us the best service. Flowrox experts visited the site several times, closely examined the pump station and the previous automation system. They carefully listened to our needs. Flowrox delivered not only what we required, but also improved pump station operation, collection and analysis of data. After initial meetings when everything has been agreed, I didn’t have to do anything. Flowrox provided a turnkey solution to our problem,” explains Sami Huotari, Site Manager at EKJH.

Sami Huotari, Site Manager at EKJH.

Flowrox’s goal is to provide complete solutions. “In EKJH’s case we programmed and installed the automation system. Because we needed additional electricity installations, we sub-contracted another company to do the job. We do not want our customer to worry about who will do the electricity installations, plumbing, programming, general project management … We wish to save customer’s time and provide a complete solution from one place and one company”

Tero Ahonen, Development Manager for Smart Solutions, Flowrox.

Real-Time Pump Operation is Only One Click Away

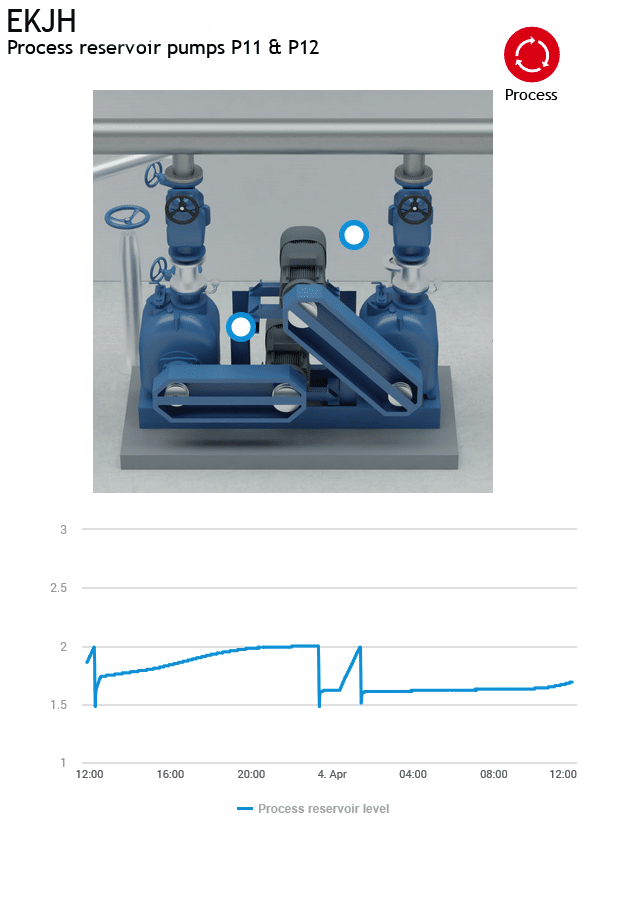

One of the main tasks of the new automation system is collecting data from the pump station (eg. quantity of pumped wastewater). Even before the previous automation system broke down, data has not been complete and still required from Huotari to personally visit the pump station on a regular basis. When the system broke down, the situation worsened and data had to be collected regularly by pen and paper, which required a lot of additional work and time.

New automation system provided by Flowrox is connected to MalibuTM online portal. It presents collected data online and shows a real-time situation of the pump station. “Now I can do everything from my laptop or smart phone. There is no need for me to drive all the way to the station and read data manually from every single pump. I can open my laptop and with a few clicks, I can get a ready-made report. MalibuTM saves me a lot of time and trouble,” tells Huotari.

MalibuTM Predicts Failures and Optimizes Operations

Another important upgrade is automatic reporting of (predicted) failures. Based on decided criteria and analysis, MalibuTM informs the user by email before a more serious failure could occur. “Compared to regular visits in the past, I haven’t visited the pump station for months. I can see everything from my phone or laptop. I don’t even need to log in to the MalibuTM portal as I get the alarms to my email. I first check from my laptop what is happening and then decide if it’s necessary for me to personally inspect the pumps,” adds Huotari.

Wastewater tank is situated under the pump station. Especially in the spring time when snow is melting, the water level can rise fast. If the pumps are not adjusted accordingly, the tank can easily overflow. To eliminate this risk, Flowrox recommended adding a frequency converter to the leveling tank pump. It controls the pump output flow according to the current tank level. If the water level suddenly rises above the limit, it automatically adjusts pump operation to a higher rotational speed. MalibuTM sends notifications about any adjustments via email. Those automatic adjustments are extremely important since they prevent bigger errors and eliminate more serious failures. “Without MalibuTM, I would notice something is wrong much later in the process. Pumps would keep pumping and get really stuck which would cause an interruption in the flow and unnecessary shutdown,” tells Huotari.

Flowrox Monitors and Improves Your System Even After Installation

Flowrox experts are monitoring EKJH pump station even after the installation to further improve and optimize the processes. When MalibuTM starts to collect and analyse data, it benefits from autonomous machine learning process. Analysis can be adjusted to a specific process, which results in accurate prediction of failures. “After installing MalibuTM to EKJH’s pump station, we saw how the waste water flow is really acting. Now we can make even more improvements to the system. A good example was decreasing the speed of levelling water tank pump. This small adjustment prolongs the continuous pump operation time and assures even flow towards waste water treatment plant,” explains Ahonen.

Even though the system did not experience any technical difficulties after the installation, the development continues. There are more possibilities to boost pumping process efficiency, reach better results and lower the costs. In EKJH’s case the preventive maintenance can be improved by installing additional sensors. Flowrox is a trusted advisor with over 40 years of experience about pumping solutions and strives to offer best long-term solutions.

Remote, online view of Flowrox MalibuTM: exact model of the real EKJH pump station.

Customer:

Etelä-Karjalan Jätehuolto Oy (EKJH),

Waste Management Company, Lappeenranta, Finland

Process application:

Pumping wastewater from EKJH to Lappeenranta wastewater treatment plant

Flowrox products / solutions:

Flowrox Smart SolutionsTM, MalibuTM monitoring and automation system