System-specific measuring, control and regulating systems that obtain their information exclusively from the media flow guarantee maximum functional reliability.

The VC gear type flow meters ensure highly precise distance and speed measurement of hydraulic drive movements.

The measuring unit, which comprises of two high precision gear wheels, is driven by the fluid flow based to the displacement principle. The pulse is generated by contactless scanning of the tooth movement by means of two sensors. The sensors are arranged so that two incremental signals are generated, offset by 90°, which enable direction detection. This type of pulse generation improves the resolution (4-fold evaluation). This means that even the smallest distances, such as during clamping processes in machine tools, can be recorded very precisely.

The gear type flow meter is installed apart from unfavourable ambient conditions. For extreme conditions, such as in tunnel boring machines, the endangered components are designed to be extremely robust. An aluminium connection box replaces the plastic connectors and the electronic components are cast watertight.

Optionally, the gear type flow meters are available with the IO-Link technology. Thanks to its international standardisation, the IO-Link technology offers a point-to-point connection with continuous monitoring between any control level and the VC IO-Link assembly.

A version with maximised measured value resolution is also available (encoder version).

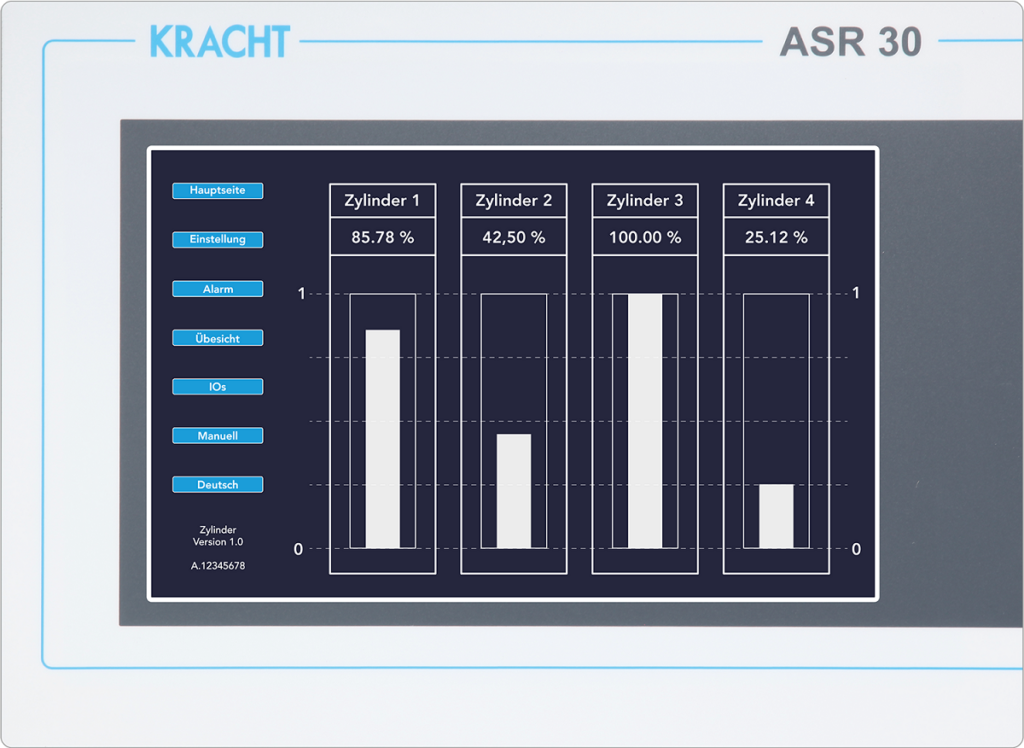

The corresponding electronics for distance and speed measurements are also available. The ASR 30 control unit can be used to evaluate any number of two channel gear type flow meters and to show the movements graphically on the display. Digital and analogue outputs as well as various bus systems are available for external processing.

In addition, the ASR 30 can be used as a IO-Link master. The programmers adapt the software optimally to the requirements of the application.

Characteristics

- In addition to monitoring the CLAMP processes, correct RELEASE processes can also be monitored

- Predictive maintenance is facilitated, as the wear pattern of a cylinder/actuator has a direct influence on its leakage behaviour.

- External leakages can be detected and stopped at an early stage if two flow meters are used per cylinder (environmental protection).

- Fault susceptibility of the overall system is reduced, as the flow meters are installed outside harsh environmental conditions (relevant in the operation of, for example, steel and hydraulic engineering equipment that can be damaged by external environmental influences)

- Reduction of the risk of plant accidents by avoiding dangerous consequential damage such as fires – caused by leakages

- Continuous monitoring of cylinder positions

- More economical than direct-measurement systems, since existing hydraulic oil is used as a sensor

- One gear type flow meter can monitor several clamping cylinders in one clamping circuit

- Durable technology

Applications

The gear type flow meter VC in combination with KRACHT electronics has proven itself for decades in the following applications:

- Monitoring clamping cylinders in machine tools

- Position detection of flood-gates

- Position detection on tunnel boring machines

- Position detection of hydraulic actuators in municipal vehicles

- Borehole depth measurement in blast charge drilling machines

- Flap position monitoring on ships