SUEZ operates regulated water systems in eight states and provides contract services to over five million people. SUEZ operates several water systems in the suburbs of New York City including SUEZ New Rochelle and SUEZ Westchester in Westchester County, New York.

Like many of the nation’s older communities, their infrastructure is aging and in need of repair. Infrastructure improvement is a critical part of SUEZ’s strategic objectives for these water systems and the company is committed to making proactive capital investments.

Challenge: To pinpoint and stem water loss quickly and easily – even in no-power situations – in order to save water, energy, and reduce their bottom line.

SUEZ needed greater visibility into their water usage and flow so that they could minimize water losses. The critical problems SUEZ wanted to solve their water leaks caused by line breaks in the water mains, and water theft by contractors and other persons. A big main break can waste millions of gallons of water, since the time it takes for the leak to surface could be weeks or even months, according to Nick Curcio, manager of non-revenue water for SUEZ. In addition, contractors often, and illegally, open hydrants to fill their water tank trucks. Since SUEZ buys water wholesale, water loss from line breaks and theft goes straight to the bottom line, driving up costs for customers and creating potential safety issues.

Solution: An accurate water measurement tool, featuring Siemens Flow Technology, as the primary input to SUEZ’s water balance model.

SUEZ began by closing interties between systems, and routing water to locations where it could be measured more easily. “We broke the systems down into smaller zones,” says Nick Curcio. “We wanted to minimize closed valves and made sure that no unmetered water crosses the boundaries between systems.” They called these zones DMAs or District Metered Areas. Water flow into and out of the DMAs is to be measured and uploaded to the system operating model.

They created a Big Data-driven proprietary model of their water systems using historical data to determine baseline water usage in each main, in each zone, in each system. They used as-built data to build a hydraulic model of the system and analyzed the historical data for usage against the hydraulic model. In order to compare real-time water usage to the baseline water usage they developed from history, SUEZ needed a way to economically measure water flow and pressure at the boundaries of each zone in the systems. “These water flow meters and pressure transmitters needed to be rugged, durable, and able to operate in no-power situations during storms and power outages, to continue delivering data to the model,” says Keith Kolkebeck, director of technology solutions for SUEZ. “We knew we needed a battery-operated solution.”

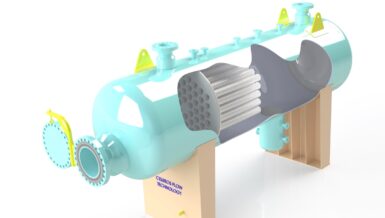

Kolkebeck and the SUEZ staff searched for devices that could meet those criteria and determined that the Siemens Sitrans FM MAG8000 would work as the heart of the system. The Sitrans FM MAG8000 is designed for very low power applications like distribution systems and agricultural irrigation systems. It is designed to have excellent performance at very low flows, and high accuracy at the upper end of the flow range.

The transmitter can be remotely mounted.

Mounted meter body

The transmitter can be remotely mounted, as seen in Figure 2. This, according to Kolkebeck, was an important feature, because of the difficulty of entering a manhole located in the street. The meter body can be mounted in the main running under the street, as in Figure 3, but it isn’t usually necessary to enter the manhole. In some cases, Kolkebeck says, the meter body was direct buried, with no manhole. Stopping traffic and working in the middle of the street is dangerous, and field personnel appreciate not having to do it.

In Figure 4, the flow transmitter, the 10-year life expectancy battery, and the cellular data logger and cellular modem are mounted on a standard back panel. Instead of being installed in a cabinet, the back panel is installed on a set of slide brackets in a sidewalk-mounted meter vault (the same sort of meter vault a large household water meter would be mounted in). The SUEZ technician flips open the meter vault lid and pulls the back panel up and onto the sidewalk for inspection, maintenance or repair. It is not necessary to block the street or stop traffic to do any expected maintenance including changing the battery. Putting the devices on the back panel in a meter vault instead of a standard cabinet also reduces the potential for vandalism, since nobody can see what’s in the vault.

Using the Sitrans FM MAG8000 conical flow tube design, and the Siemens sizing program, Curcio says that SUEZ was able to use the smallest meter size possible in each application. This improved the low flow accuracy to the point that, on a minimum flow day, the installed meter accuracy was 2% of rate, and on an average flow day, the accuracy improved to better than 1% of rate, installed. Siemens collaboration with SUEZ was critical to fine tuning the accuracy of the input to their hydraulic model.

The flow meter measures flow and the data is stored in the wireless data logger at one-minute intervals. Once a day, the data logger’s cellular modem uploads the day’s data to the SUEZ SQL Server enterprise database, called EOps, a proprietary program with database that is SUEZ’s meter data management system.

Results: Water savings of 1 MGD and detection times shortened to less than 24 hours.

Curcio says that they started with 26% water losses in New Rochelle, and 28% in Westchester, so it was essential that SUEZ get a handle on stopping the losses. “With the data from the flow meters,” Curcio says, “we can see water used, consumed or lost in the EOps system.” The data has been able to pinpoint leaks that were previously thought to be simply part of the usage baseline. “A spike in usage indicates a leak,” Curcio says, “and the flow data is fed back to the model to triangulate where the leak is.”

“We are finding leaks in hours, not days,” Curcio says. “Our standard time to fix is now less than 24 hours, where it might have taken several days before. The meter data allows us to pinpoint leaks within a few feet. This means less time digging up the street, and a faster time to repair.”

The time the leak happens to the time the leak is found and then repaired has also been shortened. In some cases, it is only minutes. A 12-inch main flowing at 10 ft/sec. produces around 3,400 gallons per minute of flow. If it takes 25 hours to find the leak, the lost water will be over 5 million gallons.

Lost water is also an energy issue, not just a production issue. It requires energy to pump the water into the distribution system. Reducing water leaks and water theft also reduces the amount of energy necessary to operate the system. It permits SUEZ to operate pumps at off-peak times, further saving electricity.

According to Curcio, a 1-million-gallon leak in New Rochelle is roughly equal to five percent of production. Finding and repairing a leak like this is critical. Curcio says that the savings in New Rochelle in previously lost water have been over a million gallons a day. Westchester’s results are similar.

Eventually, Curcio says, they will want to move to a fully integrated GIS (Geographic Information System) database that is further integrated with the enterprise database, EOps. They expect to be able to use the GIS system to pinpoint leaks and water thefts with even greater precision than the current system can. It is certain that the SITRANS MAG8000 will be an important part of the system going forward.

- Reliability: A 10-year battery life provides consistent monitoring

- Ease-of-use: Remote mounting enables freedom for installation, making maintenance easier and safer.

- Cost savings: Siemens experts can help you design the exact solution you require for your installation, so you only pay for what you need.

- Operational Efficiency: the MAG8000 includes a built-in wireless automated meter reading/advanced metering infrastructure (AMR/AMI) solution designed for use in Water Fixed Networks. Usage data from any site can be directly accessed via the Internet using a standard browser and secure password protection.

- IP68 / NEMA 6P, compact and remote with connectors and factory-mounted cable

- Bi-directional measurement – only one meter required for measurement in both directions

- Zero maintenance – no moving parts