The world’s smallest dual-tube coriolis mass flow meter: high precision measurements within 150 mm.

For this reason single tubes are often favoured for the measurement of very small flow-rates, where the coils are mounted to the chassis and not on the tube. However, with the use of just one measuring tube the influence of external interferences increases dramatically. To reduce this sensitivity and at the same time delivering accurate measurements at very small flow rates, Heinrichs Messtechnik has developed the dualtube Coriolis principle to a new level. In this new state-of-the-art technology, the sensor coils are no longer mounted onto the tubes, but rather between them, thus freeing the measuring tubes from the influence of the coils weight allowing for extremely small tube diameters in dual-tube design. The result is the world’s smallest dual-tube Coriolis Mass flow meter: The High Performance Coriolis (HPC). With an installation length of just 150 mm it is now possible to achieve high accuracy measurements with deviations of just ± 0.1 percent. Furthermore, the sensor shows insensitivity to temperatures of up to 180 °C, to pressures of up to 600 bar as well as to strong vibrations.

“Market observations have revealed an open gap in the measurement of small flow rates”, explains Frank Schramm, the managing director of Heinrichs Messtechnik GmbH. The current problem is that the state-of-the-art stipulates the use of dual-tube technology, where the magnets are mounted to one tube, the exciter and sensor coils to the other. However, for very small flow rates this principal has a decisive limit. For example, where extremely small flow rates demands a tube diameter of just 1 mm, the vibrating behavior of the coils weight can influence the measurement results significantly. “Therefore it is common practice to use one tube systems for these applications, in which the coils are mounted to the chassis of the sensor.

This system has the decisive disadvantage in that the second tube, which also serves as a measurement reference, is omitted, requiring that the sensor coils be mounted on to the chassis of the enclosure making the sensor more susceptible to vibrations and other disturbances. For this reason, Heinrichs Messtechnik GmbH has set as its objective, the development of a high precision, shock resistant Coriolis Mass Flow Meter. Emerged is the High Precision Coriolis – short HPC – with its installation length of just 150 mm the smallest Coriolis mass flow meter in dual-tube design.

Reducing disturbance influences by positioning the sensor coils between the measuring tubes.

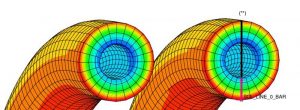

“Due to the sensitivity single tube Coriolis sensors, a costly mechanical decoupling is often required, rendering them inappropriate for many applications. Our quest was therefore to find a means of unifying a dual tube design with very small diameter tubes”, explained Schramm. Since the fundamental problem lies in the weight of the coils, which when compared with tube diameters of 1.5 mm or less present a significant weight, Heinrichs Messtechnik adopted the following solution: The conventional approach of mounting the coils onto the tubes was abandoned in favour their mounting on a printed circuit board mounted between the tubes. This method also enables the use of four sensor coils instead of two, as is usually the case with dual-tube Coriolis, providing a higher resolution.

On the measuring tubes themselves only very light magnets are mounted, which, with a weight of only 0.08g, have little to no influence on the vibrating behavior of the tubes. Instead of conventional brazing, the magnet holders are mounted onto the tubes using a special laser-welding technology. Utilizing this method, Heinrichs Messtechnik aims at keeping the production costs of the sensor to an absolute minimum, it not only allows for a stress-free connection, but also eliminates the time-consuming and elaborate process of brazing in a vacuum oven.

Insensitive to external influences

Using the dual-tube design, the new HPC displays extreme insensitivity towards external influences, allowing for precise measurements with a maximum deviation of ± 0.1 percent of the mean value and a Zero-point stability between 0.001 and 0.005, making a mechanical decoupling in most cases superfluous. Owing to the measuring tubes high working frequency of over 200 Hz, the coupling of installation vibrations or similar oscillations into the measuring system is prevented and so with avoiding fault signals. A further advantage in mounting the sensor coils on a motionless PCB is the elimination of open wiring within the sensor, as is the case of standard commercially available devices. This wiring often presents a vulnerable weak point, since the wire and its point of connection must vibration continuously with the frequency of the measuring tubes.

With the exception of the laser welded measuring tubes, the HPC consists essentially of a solid drilled and tapped stainless steel block. Furthermore, the HPC has been stripped of a splitter at the inflow of the tubes, instead possessing a reservoir – in which the process pressure distributes the fluid exact into the measuring tubes, hence preventing flow disturbances generally caused by splitters. This technique has the timesaving advantage of one less component to weld as well as one less potential material stress source. The result is an extremely robust device capable of withstanding temperatures and pressures of up to 180 °C and 600 bar respectively. “In principle, the device may also be ordered with Hastelloy tubes and other alloys”, added Schramm.

Variable Assembly Concept

For flexible installations, different constructive variations of the HPC are available: Besides the traditional Inline Version, which can be inserted directly into the process line, there are three further models available, which are suitable for either wall mounting, by means of wall brackets, or may simply be placed on a table. “For our Table model there are two available options: either with the measuring pipes pointing downwards below the supply line or pointing upwards above the supply line. For the measurement of gas, upward pointing tubes are recommended to prevent any issues with fluid collecting in the tubes. The same also goes vice versa for the measurement of fluids”, Schramm remarks.

For flexible installations, different constructive variations of the HPC are available: Besides the traditional Inline Version, which can be inserted directly into the process line, there are three further models available, which are suitable for either wall mounting, by means of wall brackets, or may simply be placed on a table. “For our Table model there are two available options: either with the measuring pipes pointing downwards below the supply line or pointing upwards above the supply line. For the measurement of gas, upward pointing tubes are recommended to prevent any issues with fluid collecting in the tubes. The same also goes vice versa for the measurement of fluids”, Schramm remarks.

Collectively, the devices are available in three measuring ranges:

0-20, 0-50 and 0-160 kg/h. On request other adaptations are also available, for example, customer-specific enclosures, connectors or interfaces. In particular for the chemical and semiconductor industry, fully-welded stainless steel enclosures are also available.

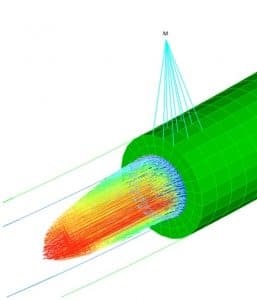

Rapid development success with High-End Simulation

The whole development phase took a mere 1.5 years. To achieve this short development time, Heinrichs Messtechnik utilized a state-of-the- art simulation technology. “By these means the required number of prototypes was drastically reduced, reducing so with development costs significantly”, Schramm says contentedly. Furthermore, with the aid of the simulation technology customer-specific requirements can be captured and individual solutions presented in the shortest of time.

The whole development phase took a mere 1.5 years. To achieve this short development time, Heinrichs Messtechnik utilized a state-of-the- art simulation technology. “By these means the required number of prototypes was drastically reduced, reducing so with development costs significantly”, Schramm says contentedly. Furthermore, with the aid of the simulation technology customer-specific requirements can be captured and individual solutions presented in the shortest of time.

The HPC was presented for the first time on the Hannover trade fair from 23rd to the 27th of April, simultaneously being the official launch of sales. Furthermore, ATEX and IECEx approvals are also planned as well as a patent registration of the technology. Parallel to the launch of sales, Heinrichs Messtechnik is also working on a new miniaturized transmitter with flexible interfaces, specially designed for compatibility with the HPC.