Challenge

The wastewater treatment plant needed an accurate and reliable way to measure and control the flow of wastewater into a splitter box to two separate clarifier basins. The customer’s plant operators would “eyeball” the flow in an attempt to equalize the inflow to each basin. The previous instrumentation incorporated a pressure sensor located in the splitter box. The pressure sensor immediately clogged and rarely operated.

The customer had no way to control the flow which must be equal in both basins for optimum treatment. The plant supervisor needed to find a reliable and accurate method to measure the flow into the basins, therefore enabling a more efficient plant operation.

Solution

A Siemens sales representative suggested that the customer try the Siemens HydroRanger 200 controller. The HydroRanger 200 uses proven, continuous, ultrasonic echo ranging technology to monitor water and wastewater of any consistency up to 15 m (50 ft) in depth. The HydroRanger 200 is ideal for the wastewater industry because, unlike contacting devices, it is immune to problems caused by suspended solids, harsh corrosives, grease, or silt in the effluent, reducing downtime.

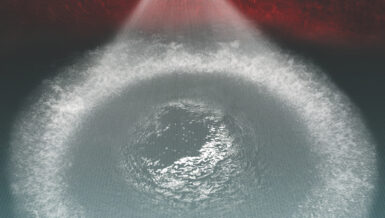

The customer gave Siemens a three-month trial to prove the efficiency and reliability of our system at their wastewater treatment plant. When the trial period concluded, a purchase order for 11 systems (HydroRanger 200 and XPS-10) was issued. This would give each WWTP in the county some of the tools necessary to help them run a reliable and more efficient plant. For these wastewater plants, the HydroRanger is used to monitor the flow of wastewater from a splitter box to the clarifying basins. A submerged, movable weir controls the flow. An XPS-10 transducer is mounted on the weir structure. The transducer measures the level of the water as it moves up and down in the weir. The HydroRanger controller calculates flow using a level versus flow curve and provides a signal relative to the flow.

Benefits

For water authorities, municipal water, and wastewater plants, the HydroRanger 200 controller is an economical, low-maintenance solution delivering control efficiency and productivity needed to meet today’s exacting standards. It offers single- or dual point monitoring with six relays standard, as well as digital communications with built-in MODBUS RTU via RS-232 and RS-485. Instrumenting the splitter box weirs with the HydroRanger 200 units saves the wastewater treatment plants time and labor in ensuring the flow to each clarifier basin is correct.