Drawing on its 40 years of experience in automating continuous and batch processes, A3D has developed a product that reflects an understanding of the engineering needs of the industry to ensure effective terminal operations.

Working with Lizard Designs, A3D’s 4D Lizard enables the linking of its 3D technologies to clients’ management systems.

Locating the correct asset in an asset management system

Typical asset management software requires an asset number/code to locate asset details. The asset number is located either from piping and instrumentation diagrams or from visiting site and locating the asset to record its physical asset tag. Traditionally, this raises issues with P&IDs not being up to date and site tags being broken, painted over or lost.

Locating an asset is one of most important factors – not only do professionals want to speed up the process of locating correct asset codes or locations, but to reduce the chances of incorrectly identifying asset as a result of human error. Speeding up the process of locating an asset’s code or physical location provides the end user more quality time with the set task.

Without an asset number, personnel are unable to research anything as the asset management system has no navigation facilities incorporated. And worse, if the asset code cannot be identified, typically people create a new code for the asset, with all prior asset history and data lost.

Current issue: Time taken in collecting asset data

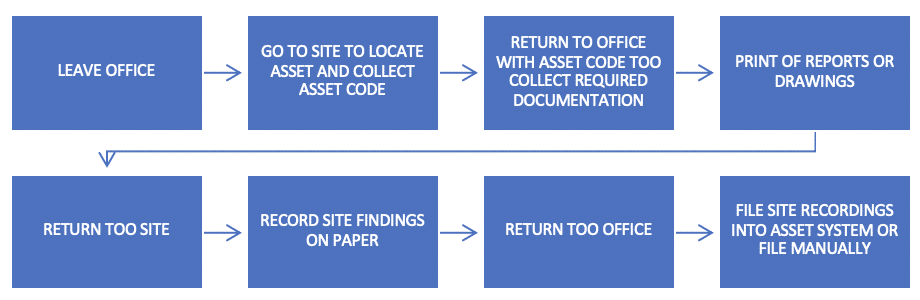

Traditional methods used to collect the site data, necessary for populating systems such as asset maintenance, are time consuming on resources. This heavy resource demand will impact on normal duties relating to the operation of a terminal and will involve the updating of paper records. These records requiring printing to use on site before results are collated on return from site survey.

Technologies such as IoT and site instrumentation allow site data to populate systems autonomously. This provides a live feed of data such as temperature, pressure, level or position reducing human interaction in manually gathering data.

Beyond IoT and site instrumentation, manual systems including permit to works that are typically in paper form can become digital forms requiring less storage with the data being available for ongoing analytics. A3D can provide ATEX-rated tablets to collect data from site equipment with NFC tags that will automatically correctly identify the correct asset, display it within the company’s 3D model or PID files and give access to the asset management system, removing the need for paper completely. Servicing update information can be updated directly to the ATEX-rated tablet, which in turn updates the assert management system.

Accessing asset data

The simple flow diagram (Figure 1) represents an all too familiar tale, outlining the process required to access asset data within an asset management system and updating the data.

Operators, having recorded asset identity on site, cannot use the information until they return to their office-based computer. Unless operators can remember every detail of those assets requiring interrogation, further site visits are required.

This process is further compounded when consideration is made to the limited user access and requirements to have specialist software installed to view data, such as Autodesk products. Using 4D Lizard removes the need for software licenses and allows the user access to data without training on the individual systems. No additional computers and software licenses are required and there are no individual training requirements for each of the connected asset systems. 4D Lizard provides the access to all asset systems, displayed via the 3D model and PID files, using simple, easy to use pages.

Data locked within multiple systems

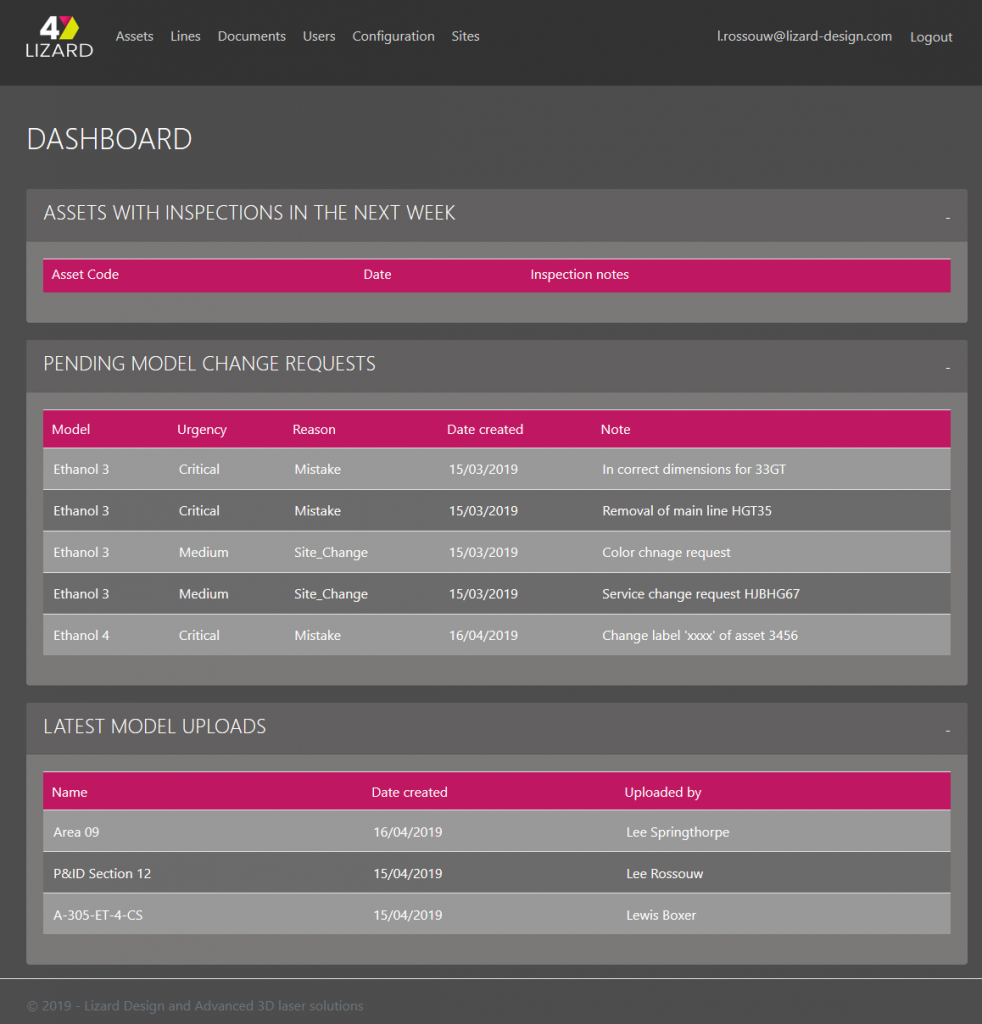

Terminals typically run with multiple software systems. These can include finance, SHE, asset maintenance, document, quality, scheduling, monitoring, work order and stock control systems. Historically this could result in a terminal running more than ten systems, each being essential to the terminal’s operations but likely each holding their own unique data for handling terminal assets. Their exportable reports would be limited by the data available in each respective system. Over time, duplication of functionality will occur across the varying systems and each system would require licensing, training and hardware to operate.

Data visualisation

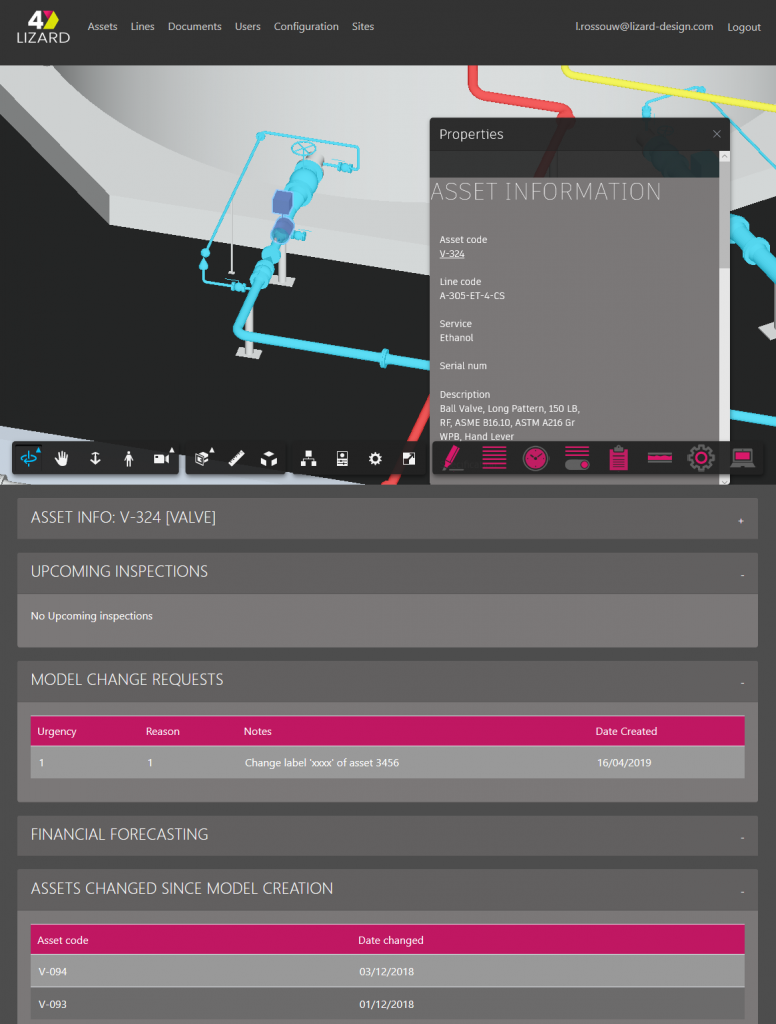

The way data is presented and visualised influences the benefits operators can gain from its use. For example, a maintenance management system schedules maintenance activity displaying only an asset code and date. However, displaying this via 4D Lizard using the 3D model file, an operator has a visual display of the assets along with their respective locations. By adding a simple 4D Lizard routine with a corresponding colour code based on when those assets are due an inspection, the operator can clearly visualise the data and see where and which assets are due for an inspection.

Using 4D Lizard, this data gathered from multiple sources can now be investigated allowing key decision makers to analyse the findings to recognise failure patterns and move towards predictive maintenance techniques.

It has been proven that the human brain’s ability to interpret data will be quicker with good data visualisation compared to traditional database tables. In turn, operators can analyse the data faster and predict maintenance quicker and more accurately.

Development of 4D Lizard

Clients wanting to utilise A3D’s 3D process models and smart PID files suffered from a lack of necessary hardware, software and in-house resource skill set. They wanted open access without restrictions and access via a cloud-based platform became the obvious solution.

A3D’s partnership with Lizard Design introduced a specialisation in custom cloud applications to complement the company’s services. Not only could Lizard Design upload A3D’s 3D models and PID files into the cloud, it could also transfer the model property data.

This data provides the complete identity for each model component including size, specification, service, materials, rating etc. This breakthrough led to the development of API software, enabling client asset information held within their management systems to be linked to appropriate assets within A3D’s 3D model and PID files. In short, these files would become live.

From this milestone, client ideas on new programmes running within the 4D Lizard software using this new-found connectivity started to be received and every proof of conception presentation with clients resulted in more ideas.

An engineer recently said: ‘4D Lizard is a fantastic system that will improve efficiency, reduce cost and revolutionise maintenance for the tank storage industry. 4D Lizard has the ability to slingshot petrochemical and storage tank maintenance management into the modern day.’

This served to demonstrate the restrictions on engineering in using their existing management systems, summed up by the statement, ‘management systems were designed by accounts for accounts’. Utilising asset information held within these management systems but displayed in a 3D model/PID format proved to be just what engineers were looking for.

Conclusion

4D Lizard was created to help clients:

- Locate assets quickly

- Access data freely

- Access data from different locations/sites

- Analyse data found across multiple systems

A3D has more exciting developments arriving shortly, with systems such as augmented reality, modern ATEX-rated tablets and mobile equipment, integration with IoT systems and the use with drones for autonomous 2D and 3D site updates.

For more information

This article was written by Lewis Boxer, technical director, 4D Lizard, part of the Advanced 3D Laser Solutions Group. t: 01245 407552, m: 07974 835571, e: lewis@4dlizard.com