“As per my experience, plant engineers are increasingly asking their suppliers to organize component documentation in a particular format. The VDI 2770 standard is significant in this context,” explains Michael Hasselbach, Digital Innovation Lab Expert at the AS-Schneider Group. The standard specifies the format in which digital manufacturer information must be made available in order for manufacturers, plant operators, and outside service providers to readily transfer and automatically process documents. This avoids data confusion between companies.

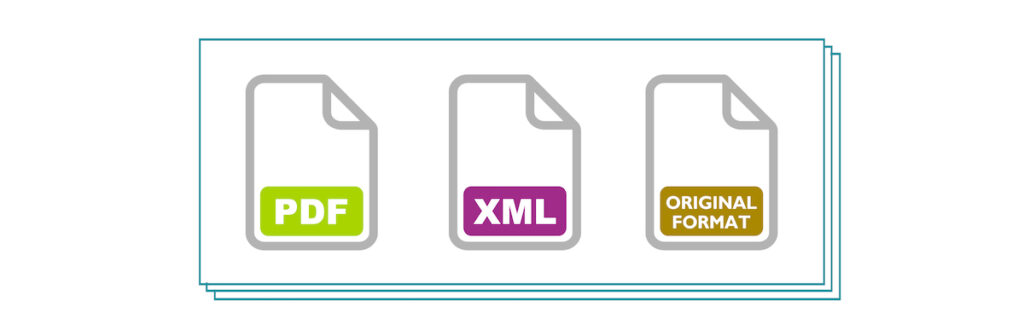

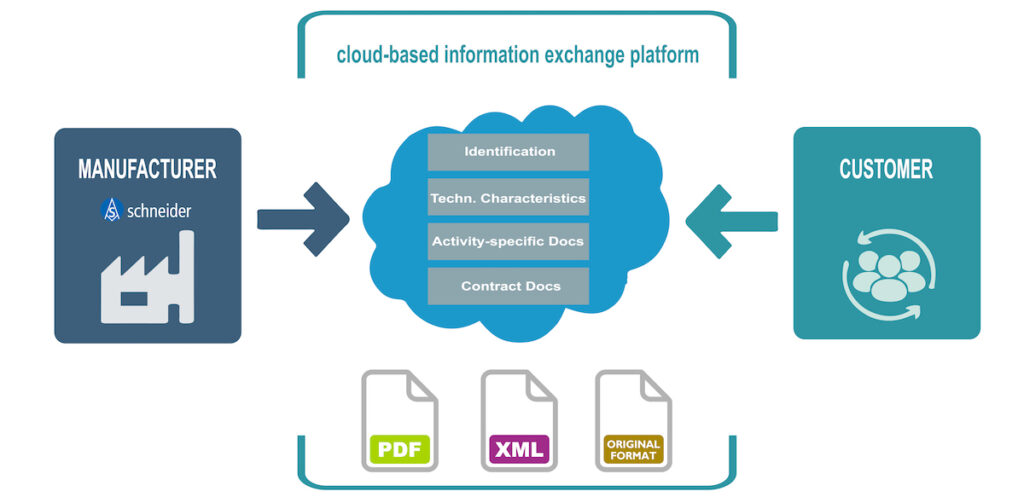

The varied information is arranged into so-called document containers (ZIP files), in accordance with standard VDI 2770. Components such as valves should be provided with a unique identifier, ID for short. For instance, this can be carried out in accordance with the requirements of the IEC 61406 standard. The ID needs to be linked to a corresponding order at AS-Schneider after which it needs to be encoded in a QR code or RFID tag. The document containers hold data in various formats. These include machine-readable XML files for simple customer-side integration with third-party software and human-readable PDF files for maintenance staff, operators, engineers, and plant engineers. “However, the original data can also be used to gather data for in-depth research. The VDI 2770 standard classifies the manufacturer’s data into the categories of identification, technical characteristics, activity-specific docs, and contract documents to provide a clear directory,” describes Michael Hasselbach.

Fast access to technical information

According to AS-Schneider, employing structured data has a wide range of benefits. For example, quick access to technical information is possible for efficient maintenance and repair. Information reaches the maintenance technician quickly. Processes become more transparent, and optimization opportunities can be identified more easily. The integration of newly acquired equipment into existing plants is easier.

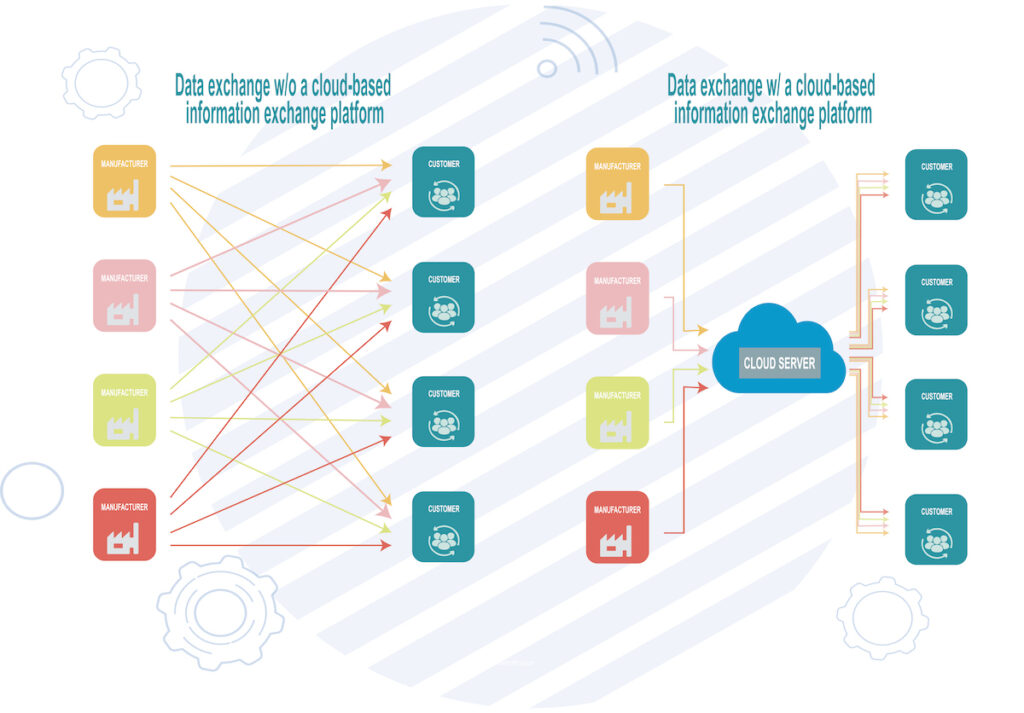

At the end of 2021, a new industry committee was established – a merger of the IEC 61406 and VDI 2770 standards groups. It resulted in the Digital Data Chain Consortium (DDCC). “Out of its work came a third technology known as the Information Exchange Platform IEP. IEPs operate in cloud-based environments. This supports the easy transfer of VDI 2770 ZIP files from vendors like AS-Schneider to third parties,” says Michael Hasselbach.

More flexibility due to various formats

Plant engineers benefit from data exchange via IEPs, according to AS-Schneider’s experience. It enables quick accessibility of every employee in the plant and short response times. The availability of data in different formats increases flexibility. The standardized format according to VDI 2770 brings more freedom. If necessary, providers can be changed immediately and without a drawn-out conversion process. “Additionally, there is an improvement in communication between manufacturers, operators, and service providers. This reduces errors and saves a lot of time,” explains Michael Hasselbach.

Plant engineers should collaborate with manufacturers who have experience compiling, organizing, and conveying digital information, proposes AS-Schneider. Important inquiries must be addressed: Does the supplier have funds set up for digital departments and internal digitalization processes? Exist any cross-functional teams with strategic objectives to prevent digitalization from being pursued solely for its own sake? However, there is additional homework for plant engineers. It is crucial to learn about recent advancements, especially those including IEP solutions, through industry associations or committees. Internally, a procedure for handling digital documentation should be started.

Intensive client use

The combination of the VDI 2770 standard and cloud-based data provision is bearing fruit in the market. Michael Hasselbach: “Our customers are making intensive use of the benefits of normalized product data, for example, to make maintenance faster and safer. All teams work with the same information from just one source. Some customers even want to make the provision of structured product documentation mandatory for their suppliers in the near future.”

And for plant engineers who do not yet have experience with digitized data, he has some advice: “I encourage you to take the plunge. You won’t regret it.”