The radar sensor supports efficient, resource-saving manufacturing processes, especially in hygiene-sensitive areas like the food and pharmaceutical industry. Among other things, this is due to its

- switching frequency: It enables quicker cycle rates and correspondingly fast level changes

- flexible connection options: Different process connections are available, from a standard thread to 1-inch universal connection for the hygienic adapter system.

What advantages does the radar sensor offer?

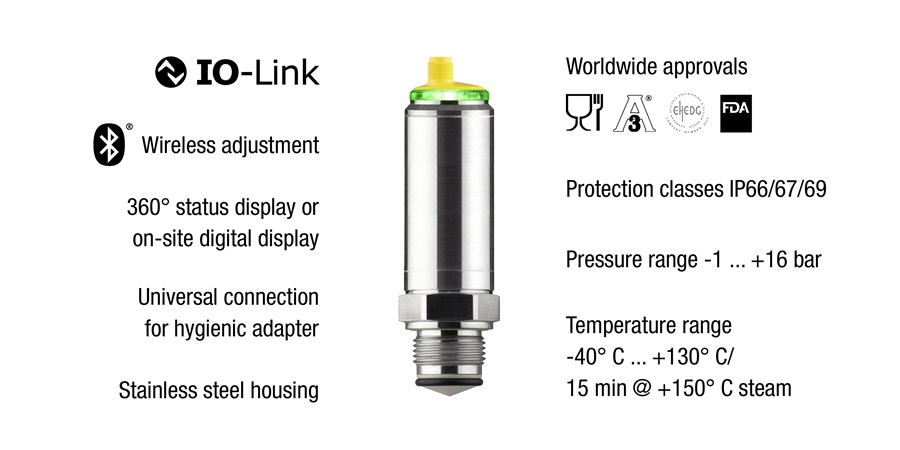

Whether with an on-site 360° status display or in a complete metal housing: VEGAPULS 42 brings the advantages of radar level measurement to factory automation.

Efficient plant operation and precise control of production steps are the basis for getting successful results from processes – for example in the food and pharmaceutical industry. Reliable measured values are extremely important here. VEGAPULS 42 delivers them with non-contact radar measurement technology and, thanks to its many other innovative features, supports optimised productivity:

- Universal communication: In the 3-wire version, VEGAPULS 42 communicates with IO-Link, is wired easily and cost-effectively via the connection.

- Simple exchange: Parameters that have been set previously are transferred directly to the new instrument by the second-generation Smart Sensor profile.

- Easy control: With the VEGA Tools app, the sensor can also be conveniently controlled and adjusted via a smartphone with Bluetooth .

Continuous radar level sensor tailor-made for hygienic applications

What does the illuminated ring do?

Is your process running effectively – even from a distance? Its the bright multi-colour illuminated ring on the sensor that makes it possible. This is what greatly enhances the visibility of the sensor and process status. The visualisation capability also increases operational safety.