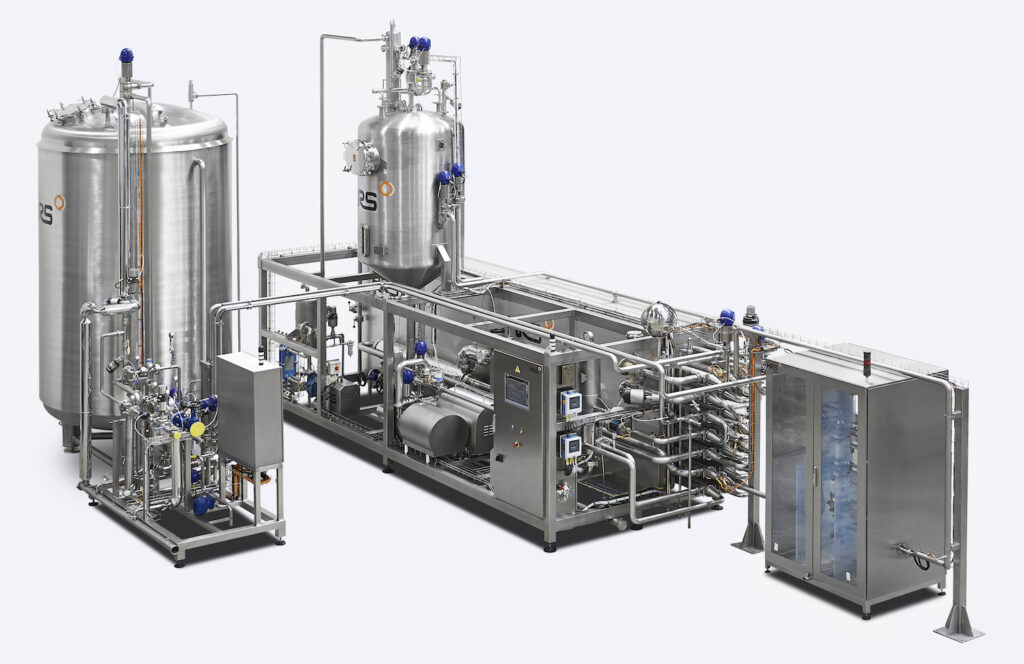

Many industrial processes require a precisely controlled temperature to ensure quality. Various thermal transfer media are used to cool and heat, including water, air, oil or mixtures of these substances. Process temperatures can be controlled reliably on the basis of the flow values and with the aid of an intelligent solution.

Although highly desirable, it is often difficult to control the temperature in a process because its measurement must be within a specified range of accuracy and have a specified degree of speed of response, sensitivity, and dependability. Additionally, temperature measurements must also be representative of true operating conditions in order to achieve successful automated control. The instrument selected, installation design, and location of the measuring points determine these specifications.

This Technology Zone offers an insight into the latest innovations in fluid temperature measurement and control.