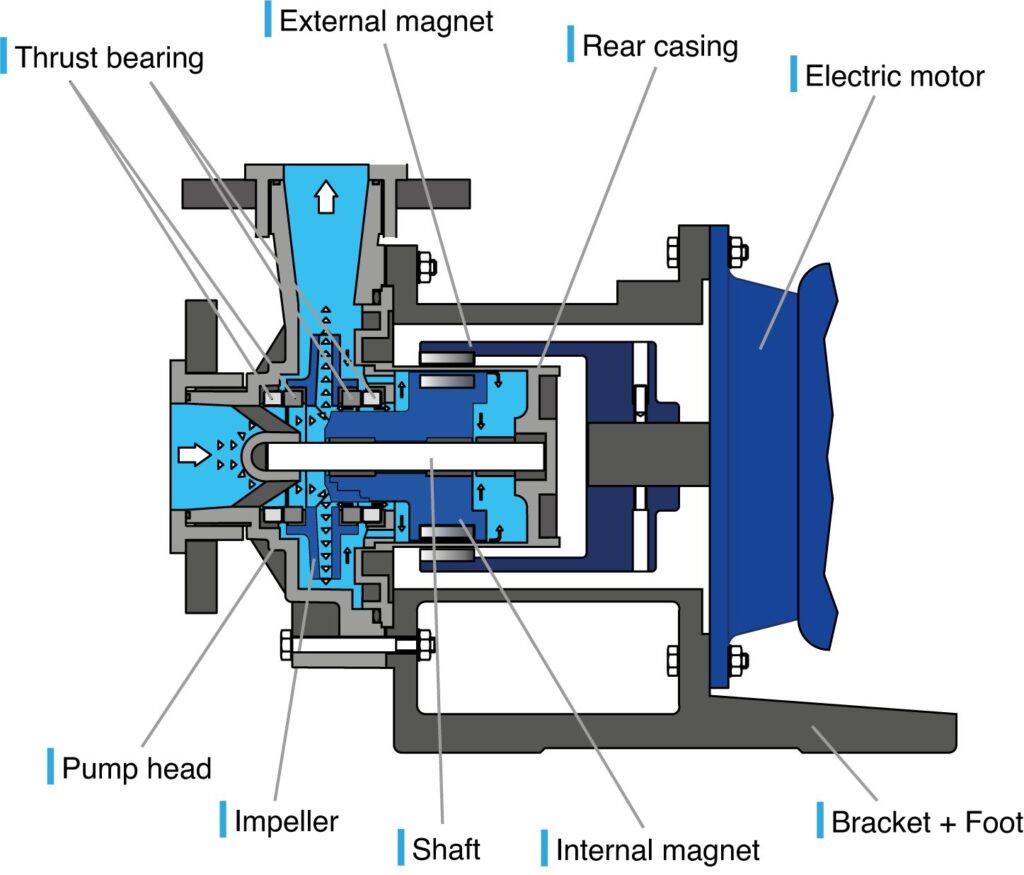

The chances of buying exactly the right pump for your flow requirements without some research are minimal. The flow rate of your system depends on the physical characteristics of the system, such as friction, static head, as well as fluid viscosity if the fluid is different from water. Different fluids have their own characteristics and are usually pumped under varying conditions, therefore, it’s important to know all relevant product and performance data of a pump before selecting the right one.

In order to select the right pump, some steps need to be considered. First, the flow rate should be determined. In industrial settings, the flow rate depends on the production level of the plant. Careful analysis of the interaction between processes is required to determine the exact flow rate required. Second, the static head and friction head should be determined. The static head can be determined by measuring the different heights levels, friction head depends on the flow rate, pipe size, and pipe length. Third, the total head should be calculated by summing the static head and friction head. Finally, you are ready to select the right pump depending on your required flow rate, static head, and friction head.