Instead, wouldn’t we want to contain the sewage? Keep it confined within a system while still being pumped onward between homes and treatment works?

Thankfully, that’s exactly what OverWatch® Direct In-Line Pump System by Industrial Flow Solutions™ does. Originally invented in Europe, it first garnered attention and wide usage in areas or regions that needed a more delicate approach, but it has since been proven to be a better solution for almost any station.

A Smarter, More Efficient System.

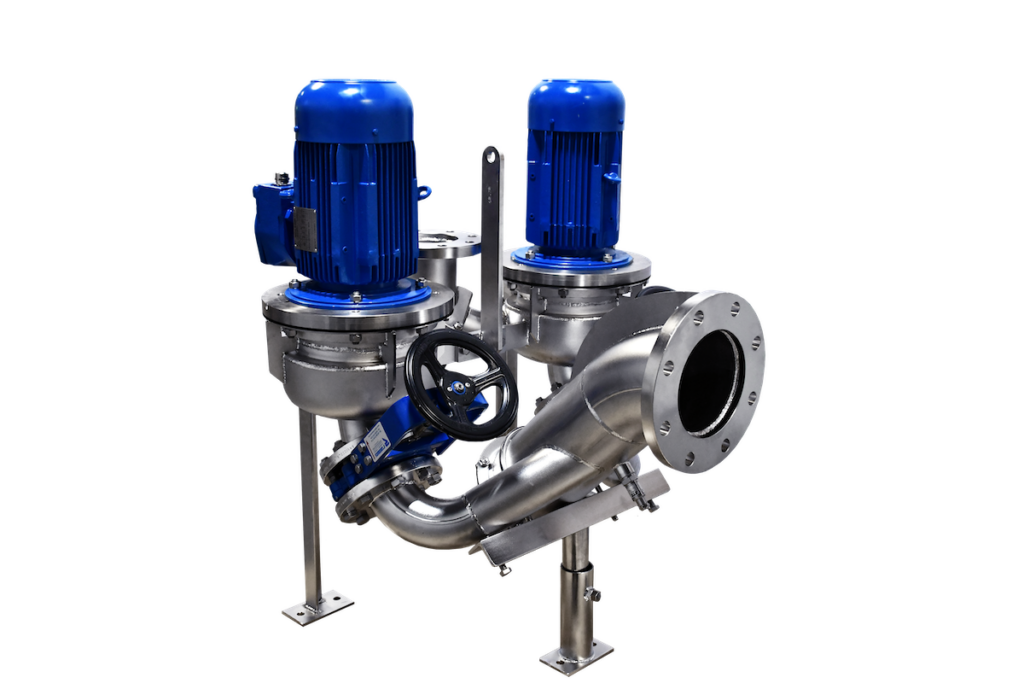

The OverWatch® is referred to as a Direct In-Line Pump System; in essence, this means it lifts the influent from the point of entry – so no wet well is required. The OverWatch system sits in a ‘dry’ well, with two (or more) pumps with ‘smart sensing’ to adjust in real-time to manage the flow. At peak periods, they run more; quieter, they cut off and only run when required. And no need to worry about capacity limitations – in nearly all wastewater systems, most capacity exists in the pipes rather than the wet wells! OverWatch also includes a few different yet clever non-clog devices, including a DERAGGER® electronic system, which also provides remote monitoring and the patented DIPCUT® impeller for self-cleaning operation, optional for select OverWatch models up to 18.5 kW (25 HP).

The OverWatch® is referred to as a Direct In-Line Pump System; in essence, this means it lifts the influent from the point of entry – so no wet well is required. The OverWatch system sits in a ‘dry’ well, with two (or more) pumps with ‘smart sensing’ to adjust in real-time to manage the flow. At peak periods, they run more; quieter, they cut off and only run when required. And no need to worry about capacity limitations – in nearly all wastewater systems, most capacity exists in the pipes rather than the wet wells! OverWatch also includes a few different yet clever non-clog devices, including a DERAGGER® electronic system, which also provides remote monitoring and the patented DIPCUT® impeller for self-cleaning operation, optional for select OverWatch models up to 18.5 kW (25 HP).

Reducing Odors, Reducing Risk.

With all waste contained within the pipes or pump and no wet well required, odors are eliminated. This also means that maintenance can be carried out in a dry, odorless environment—with staff no longer exposed to hazardous odors, bacteria, or Hydrogen Sulfide (H2S) gases. Any danger of explosions is also greatly reduced.

Improved Environmental Impact.

As the OverWatch bolts straight onto the influent pipe and there is no requirement for an entry chamber, a new OverWatch installation requires a lot less excavation and concrete, thereby reducing the overall environmental impact. Plus, the pumps only run when they really need to and are always clean, reducing energy consumption as well.

Save time & money with Easier Maintenance.

Installing, checking, and maintaining pumps and systems in a dry, safe environment is not only safer—it is also much quicker and cheaper. Combined with a redundant dual pump design and unique non-clog technologies, maintenance will be less frequent overall, and life expectancy will increase.

From UNESCO World Heritage sites, and Swimming areas – to everywhere else!

Having been invented in France, the OverWatch system initially gained traction in pump stations where odors and exposed sewage proved a real issue. For example, one was installed in the delicate Calanques de Piana (Corsica, France), which UNESCO classifies as a World Heritage site. Here, a complete stainless-steel design was used, as the OverWatch also had to withstand regular sea spray and was moved two years after installation due to treatment work upgrades. In another example, an OverWatch was installed near a popular aquatic center, again as the odors from raw sewage were not especially conducive to a lovely family swim!

Since IFS purchased the technology, however, the OverWatch has now been installed across the US as well – in a wide variety of situations, such as:

- Industrial – sites such as food, beverage & pharmaceutical plants.

- Municipal – not just highly populated areas where odors are an issue, but also where a clean, reduced maintenance solution is preferred anywhere.

- Commercial—from hotels and hospitals to universities and residential complexes, where reduced maintenance is often a big bonus.

To find out more about OverWatch and how it is changing the world one wet well at a time, visit https://flowsolutions.com/overwatch-direct-in-line-pump-system-by-industrial-flow-solutions/.