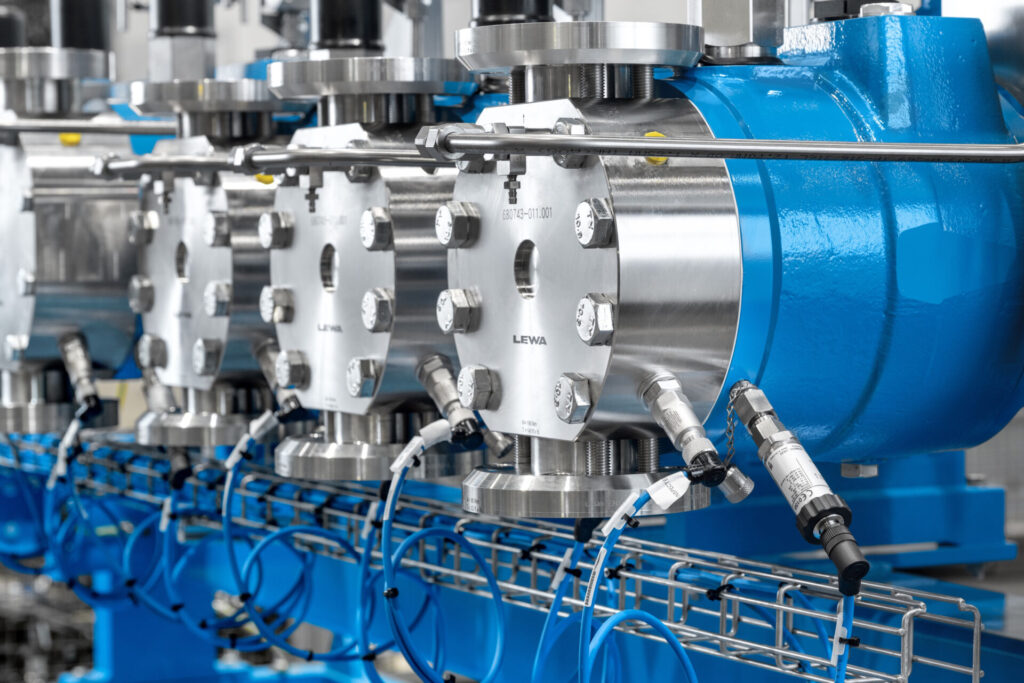

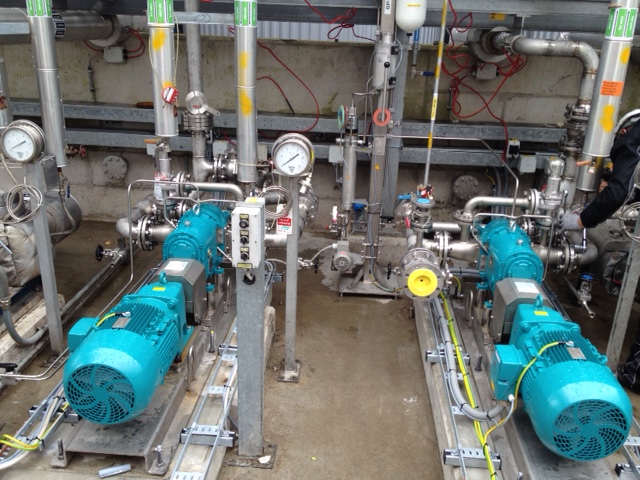

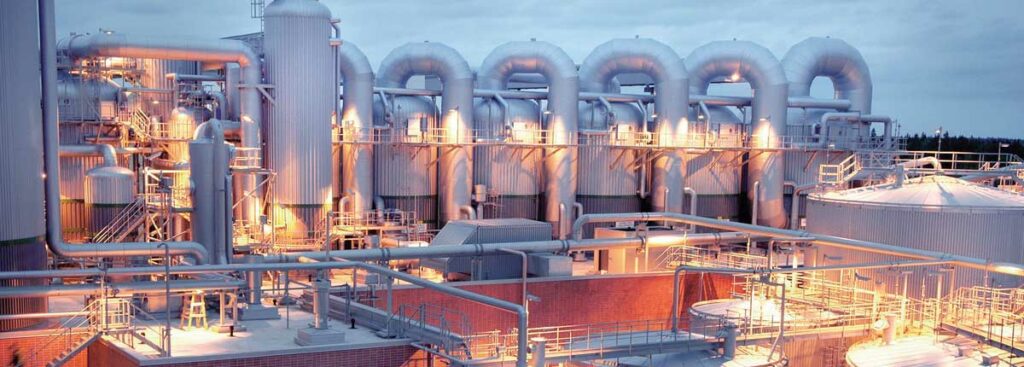

Chemical processing underpins the chemicals industry, underpinning the methods and techniques employed to convert raw materials into valuable products. At its heart lies fluid handling technology, ensuring the safe and efficient production, transportation, and utilization of chemicals through the precise movement, control, and storage of essential fluids. From the medicines we take to the materials in our clothes, chemical processing plays a vital role in the modern world.