Analogue documentation, even using a digital form, cannot be the long-term solution for the future due to its susceptibility to errors and time-consuming processing in the face of increasingly scarce resources. This can be remedied by a modern, holistic approach involving the intelligent integration of hardware and software, which is briefly described below.

Today, the demands on those responsible in municipalities, cities, districts and private companies for the documentation of critical/relevant infrastructure components for water management are continuously increasing. In addition to operators, the insurance industry has a legitimate vested interest in a functioning and documented fire protection concept. The basis for this is established by various directives and national standards. Moreover, subjects related to fire protection and water quality are increasingly becoming the focus of public perception.

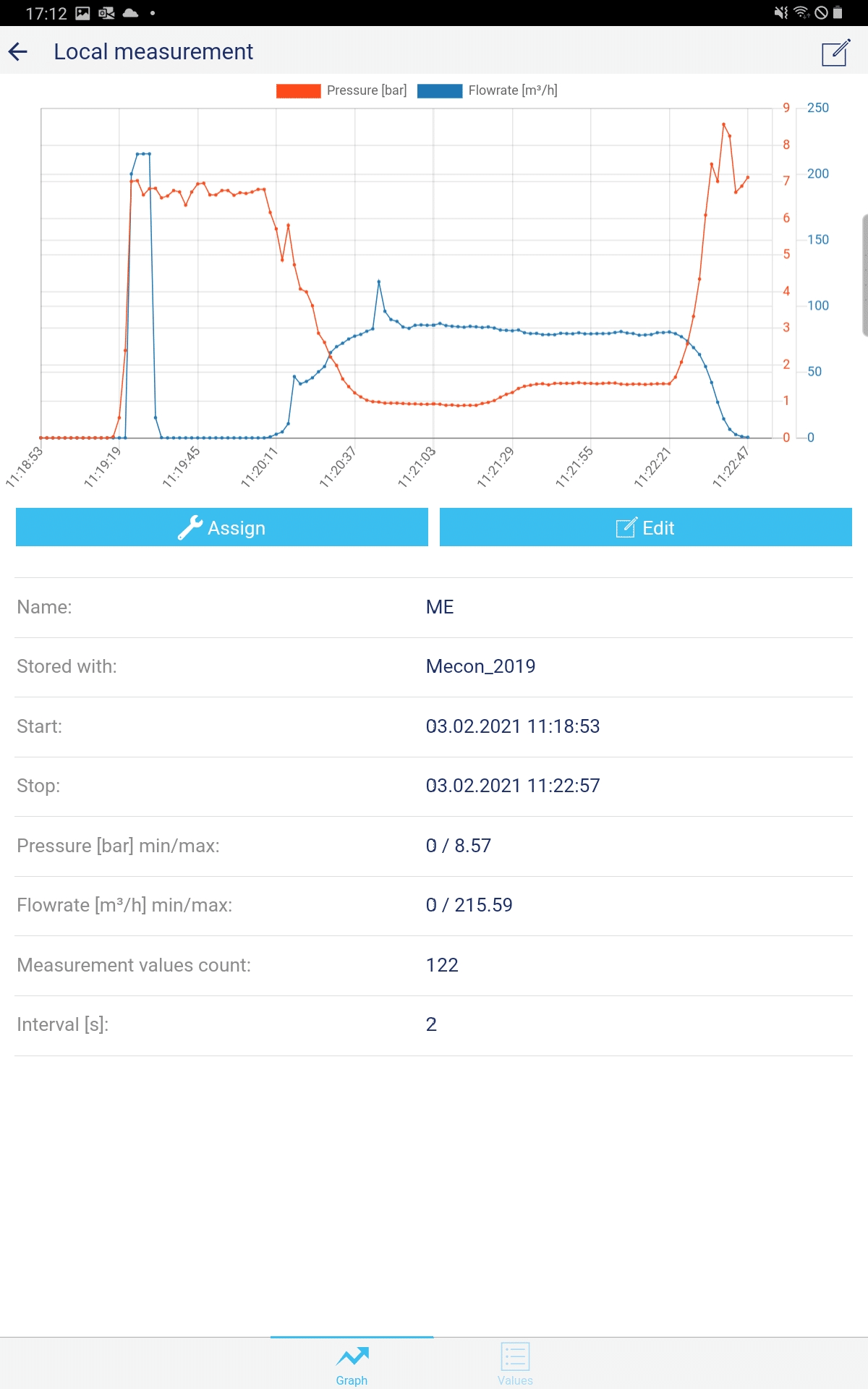

By integrating measuring technology in a powerful and tried-and-tested software solution, the status of a measuring point can be documented and called up for the entire life cycle at any time. For everything from installation to functionality and use, to maintenance and finally servicing, not only is it possible to document qualitative parameters, but also to record measurable, quantitative values error-free. In addition to the physical parameters pressure and flow rate, which are often queried in the field of fire protection, temperature and turbidity, which can be useful for assessing water quality, can also be continuously measured.

This makes it possible, through continuous measuring and documentation, to develop efficient flushing strategies based closely on actual practice, and ultimately to save resources.

Due to its structured design and the choice of sensors the portable measuring equipment is maintenance free, because it has no moving parts – which would also cause a loss of pressure. On top of that, the long battery runtime of 24 hours allows measuring campaigns to be executed autonomously, without frequent charging of the equipment.

Data storage space for up to 2,000,000 measured values as well as the three-button operation on the unit also allow use without the associated app. Afterwards data can be read out with an app using Bluetooth, and then further processed as usual. The hydrant testing units also have very high measuring accuracy in the four physical measurement values pressure, flow rate, temperature and turbidity. The base unit is equipped with a pressure and flow rate sensor. An optional temperature measuring function can also be integrated in this base unit.

Because of the mechanical construction of the sensors, the optional turbidity measuring unit is situated in a separate housing, which is connected to the base unit by cable. It is controlled using the base unit or a mobile device with the app. The high measuring accuracy of the units is documented ex factory per default with a calibration certificate from calibration systems with reference devices in accordance with DIN EN ISO/IEC 17025.

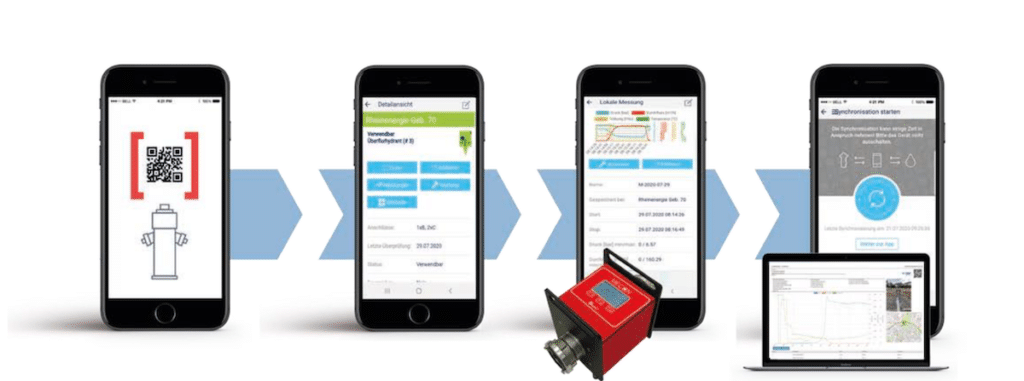

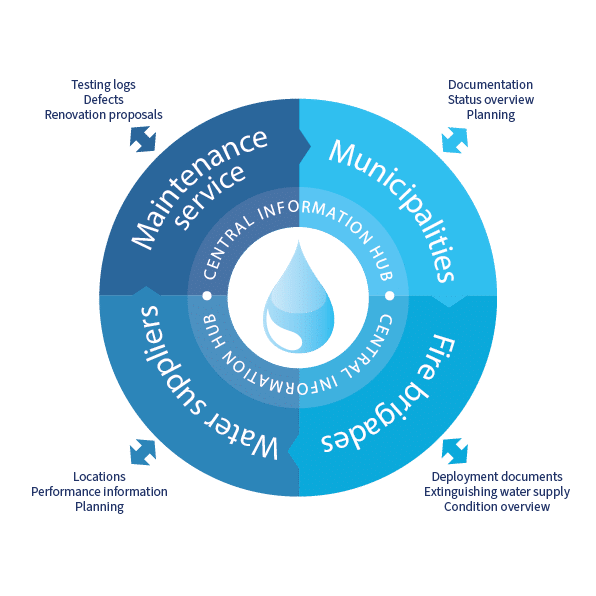

Figure 1 depicts a typical workflow for a hydrant performance measurement. In addition to the control and management of measurements, the holistic approach of a digital, centralised information platform offers even more important features (see Figure 2).

Figure 1: Workflow of a measurement

Figure 2: Information platform for different user groups

This digital system solution means that the benefits are not limited to one’s own organisation. With this system it is possible to share important information and functionality – which can be granted selectively – with other stakeholders, such as the fire brigade. So, through effective use of this digital solution it is even possible to benefit society as a whole. This is accomplished through the integration of the following components:

- Augmented reality – To easily find hydrants and valves, even in tough environmental conditions (darkness, foreign objects, …), the objects are integrated live in the camera picture of the app, intuitively simplifying the locating of the objects.

- Measurements – Easy control of the measuring unit and use of the integrated documentation of measured values, with subsequent evaluation functions. There are also extensive operating and settings options, which allow intuitive use of the hardware in connection with QR codes.

- Pipeline simulation – Based on current maintenance and network information, the hydraulic model of the drinking water network is automatically updated. If a change to the valve position is documented, for example, the model automatically adapts itself to the current state of the network. With only a few mouse clicks a simulation procedure is started and the computed pressure and flow rate conditions are soon displayed directly on the interactive map.

- QR codes – These allow the unique identification of components, and thus efficient and error-free access to the data sets in the app.

- Interfaces to GIS systems – Data on hydrants and pipeline networks already available in the GIS system can be adopted and the data can be continuously synchronised between the systems. This eliminates the need for time-consuming double data maintenance.

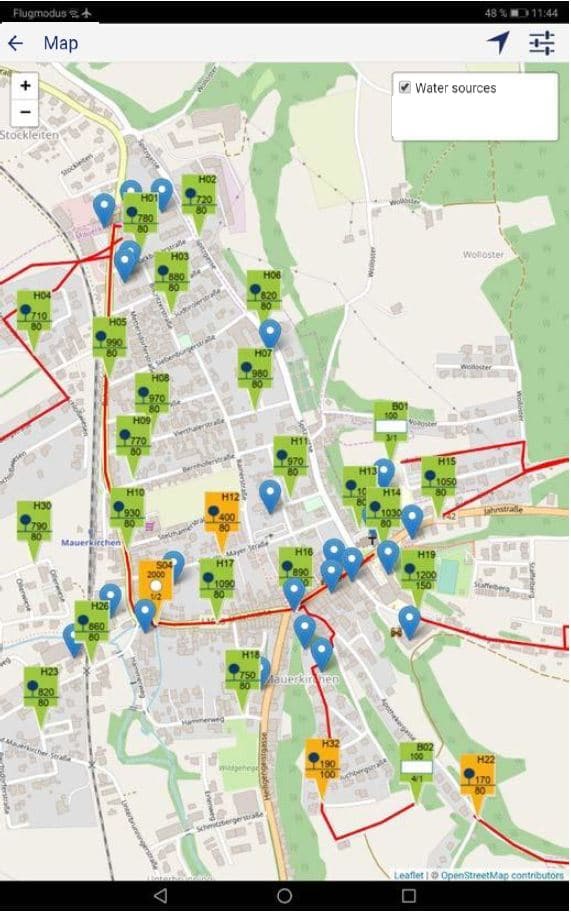

- Hydrant map for the fire brigade – It is possible to automatically generate a hydrant map for the fire brigade from the recorded data (Figure 3). Through interfaces this up-to-date data can also be automatically displayed and used in the alarm systems of the fire brigade.

- Checklists for maintenance – To document maintenance work and inspections it is possible to store checklists in the system. This way the logs can be saved in a clear way and can be called up at any time as needed.

- Maintenance and flushing planning – For optimum planning of maintenance and flushing, based on maintenance plans the system can automatically remind about approaching tasks.

- Data export as a PDF file – All logs can be exported as a PDF file, and then simply printed out and passed on as needed.

Figure 3: Overview of different components (app). A detailed view and the list of master data are stored for each component.

Figure 4: Graphical depiction of a measurement (app)

The hierarchical architecture allows a complete overview of different strategic components, ranging from a complete overview (including colour coding of status of availability) through to individual components (with entire history and master data, maintenance work, performance values and measurements) to individual measurements and measured values.

To sum up, not only does efficient digitalisation using the described solution optimise internal procedures, organise processes more efficiently, and provide more legal clarity through an integrated document management system, it can also help the fire brigade organise better, for example in emergencies when it really counts.]

FLOW METERS AND LEVEL INDICATORS

MECON: Your certified manufacturer and provider of solutions for industrial level indication and flow metering technology from Germany click here to overview the complete range of products.

Authors:

Gabriel Freinbichler, Wasserkarte.info GmbH info@wasserkarte.info, www.wasserkarte.info

Michael Jüch, Mecon GmbH m.juech@mecon.de, www.mecon.de