Mid-West Instrument in Sterling Heights defines differential pressure and provides examples of associated applications and products.

In simplest terms, differential pressure is the difference in pressure between two separate points. Differential pressure is measurable between two points on the same system or two points on independent systems. Customers investing in differential pressure gauges designed by Mid-West Instrument are able to conduct a differential pressure measurement and display the results on the gauge dial. Our instrument company serving the Midwest integrates magnetic movement, allowing for simultaneous sensing of both pressures while completely isolating the pressure gauge from the pressure chamber without using mechanical seals.

Unlike ordinary pressure gauges, differential pressure gauges can indicate small values of differential pressure even when used with high line-working pressures. And not only will our talented team show you how to test a differential pressure gauge, but we’ll also complement it with differential pressure switches supplied with reed switches or relays, enabling your system to initiate alarms, activate other equipment, or shut the system down.

In addition to gauges and switches, Mid-West Instrument has engineered a range of differential pressure transmitters to facilitate the transmission of valuable data signals. Our transmitters are microprocessor-based and equipped with proprietary magnetic sensors that contribute to remote location monitoring. And since the traditional pointer-and-dial design continues to operate, local station readout is always available too.

Applications

Filtration

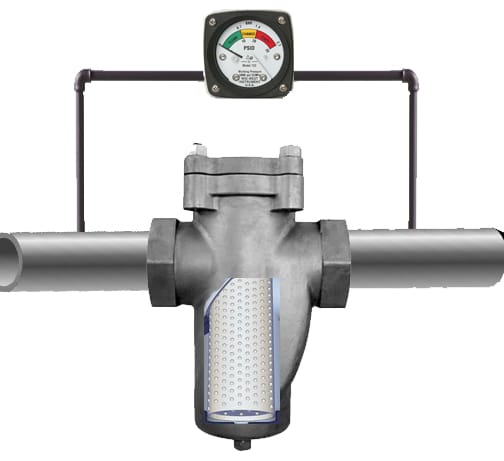

Filtration is one of the most popular applications for DP gauges. Monitoring the pressure before and after a filter allows an operator to know when a filter is clogged and needs to be replaced. Clogged filters cause motors to work harder. This in turn increases energy costs, creates greater wear and tear on the equipment, and can increase maintenance costs.

Flow Rates

Differential pressure flowmeters use Bernoulli’s equation to measure the flow of fluid in a pipe. By introducing a constriction in the pipe a pressure drop is created across the flowmeter. As the flow increases, the difference in pressure also increases.

There are several types of instruments available to measure flow. As the pipe diameter increases, the cost for flow meters increases drastically. DP flow meters are especially attractive for larger pipes because of they offer cost savings and high accuracy.

Liquid Level

Differential pressure gauges also measure liquid level. Like flow meters, there are many types of level instruments on the market. A DP gauge is a simple and relatively inexpensive solution to indicate the level of a liquid within a tank. In tank applications the high-pressure side of a DP gauge is ported to the bottom of a tank while the low-pressure side is mated to atmosphere or to the top of the tank depending on application. The DP gauge measures a column of liquid within the tank (liquid height) and displays the liquid level in differential pressure units of weight, volume, percentage, or full / empty.

Pump Monitoring

All pumps perform best when they are at, or very close to their Best Efficiency Point (BEP) as defined by the pump manufacture. This is typically 70-85% of the differential pressure between the suction and discharge. A differential pressure gauge with an integrated transmitter can alert operators to issues like cavitation, loss of flow, mechanical failure, vibration issues, excessive noise, bearing and sealing wear, etc.

Our state of the art factory is equipped the latest CNC machine tool technology, test equipment, calibrations standards, and oxygen clean room. This allows us to maintain precise tolerances and product quality with the shortest lead times in the industry.

Contact our experienced professionals to learn which differential pressure instrument best fits your application