However, there are numerous barriers which make the move to electricity challenging, such as economics, technical ability, a lack of knowledge and infrastructure issues2. Looking at industrial heat use in more detail, the scale of the electrification challenge becomes clearer. 37 per cent of total global energy consumption comes from industry: while two thirds of this is used for heat generation, approximately 80 per cent of this thermal demand is generated by fossil fuels1.

As consultants McKinsey & Company point out, ‘Overall, manufacturing, food and beverage, and agriculture and forestry are the industries most reliant on processes with low-temperature heat (less than 200 °C). In particular, manufacturing and food and beverage could see significant potential from electrification in the short to medium term, with electrification rates of 62 and 44 per cent of total energy demand, respectively, by 2030.’

Technologies for the electrification of heat

There are a number of factors which determine the optimal technology to provide electrical heat for different industrial processes. These include the required temperature, holding time and process capacity. Mature and well-established technologies such as mechanical vapour recompression (MVR) and heat pumps are suitable for temperatures from 50 to >200 °C, while e-boilers and turbo heaters are becoming more mainstream and can produce temperatures of up to 500 °C or 1,000 °C respectively. Rapid advances in induction heating are also making this method increasingly suitable for a wide range of uses, including high temperature scenarios. Speed of heat pick up is another important consideration, and one where e-boilers would be favoured over heat pumps, for example.

Again, McKinsey & Company stress that the market has not yet picked technological ‘winners’, with market maturity not expected until 2030 at the earliest. However, some technologies such as MVR and ohmic heating are already well established and utilised by HRS Heat Exchangers where appropriate.

Ohmic heating

As an example, when pasteurising fruit juice, ohmic heating (which uses electricity to heat the product rapidly and uniformly) has been scientifically shown to be highly effective at inactivating bacteria, yeast and moulds while maintaining the flavours and quality of fruit juice.

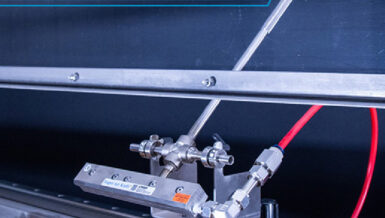

The HRS Ohmic System passes electricity between two electrodes in the product in a 1 m ceramic tube. The result is that the juice is heated to 105 °C within one second. It is then held at this temperature for four seconds before being cooled. Ohmic technology itself is not new, but the HRS? system uses the latest electronics to ensure that the temperature curve is very smooth, which helps to preserve product quality and improve process efficiency.

Depending on electricity prices, ohmic heating can be more expensive than traditional methods of pasteurisation. It also represents a larger capital investment, with the ohmic heating unit accounting for a significant part of total project cost. However, more and more clients around the world are turning to the technique because of proven benefits in terms of product quality, allowing them to access premium ‘as fresh’ juice markets, justifying the additional investment.

Mechanical vapour recompression (MVR)

HRS Heat Exchangers has also seen increased interest in using MVR for evaporation. Given the turbulent rise and fall of energy markets since 2020 this is understandable, as the electrical energy employed in MVR is normally considerably cheaper than the thermal energy needed for traditional evaporation.

Traditional evaporation techniques use a high temperature service fluid (such as pressurised steam) to raise the temperature of the product above its boiling point so that water (and other volatile compounds) is driven off, leaving a more concentrated solution. The principal source of energy for this process is therefore the fuel used to heat the water (steam) in the boiler, such as gas or oil.

In MVR, the steam which comes off the product in the evaporator is channelled into a compressor which increases the pressure (and therefore the temperature). This steam, which is now above the boiling point of the product, is then used as the service fluid for the evaporator. As the compressor uses an electric motor, the process is driven by electricity rather than thermal energy. Because the compressor reuses/recycles evaporated steam, a lot of latent heat is recovered. This makes MVR one of the cheapest methods of evaporating water in terms of operational costs, although it is not always the most suitable or cost-effective solution, depending on the nature of the product or waste stream being evaporated.

At HRS we always test any material that any client will be working with in order to determine not only the best heat exchanger solution for the evaporation process, but also what pre-treatment may be necessary. This allows us to determine the best MVR or traditional thermal-based evaporation solution for each individual project.

By Matt Hale, Global Key Account Director, HRS Heat Exchangers

(1) McKinsey & Company: Tackling heat electrification to decarbonize industry. https://www.mckinsey.com/industries/industrials-and-electronics/our-insights/tackling-heat-electrification-to-decarbonize-industry

(2) Rosenow, J. et al. The heat is on: Policy solutions for industrial electrification at https://www.sciencedirect.com/science/article/pii/S2214629625003081