Vaisala refractometers are suitable for a wide range of applications, including the production and processing of sugar, syrup, soft drinks, beer and other beverages, preserves, sweets, sausage skins, ice cream, liqueurs, ethanol, pharmaceuticals etc.

Producing sugar from sugar beet

Sugar beet is the second largest global source of sugar, after sugar cane. The processing and production cost of beet sugar is significantly higher than cane sugar, so it is particularly important for the process to be as efficient as possible.

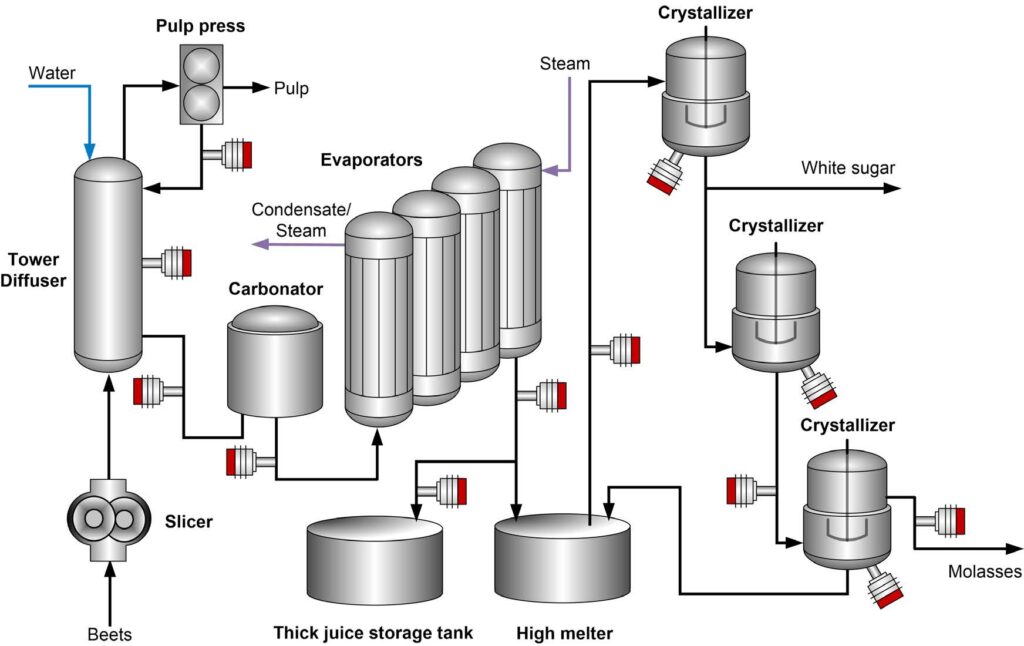

After harvesting beets are transferred to a sugar beet factory where they are washed, mechanically sliced into thin strips called cossettes, and passed on to a diffuser – a processor used for the extraction of sugar into a water solution. The diffuser process is slow, so real-time and continuous measurement of the concentration is important to monitor its progress.

The juice from the diffuser contains sucrose and some non-sugar impurities, and is purified in a two-step process. Lime (Ca(OH)2) is added to precipitate impurities that can be filtered out to produce a calcium carbonate-rich sludge that is pressed and can be used as an agricultural fertilizer. Carbon dioxide is bubbled into the solution to remove any remaining lime. The resulting solution is called thin juice, which is heated and pumped into multiple-effect evaporators to create a thick juice, with a dissolved solids concentration of 50-75%.

The liquor is concentrated further in a crystallizer by boiling and then seeding with fine sugar crystals. As the crystals grow, the sugar content of the liquor decreases. The resulting sugar crystal and syrup mix is called a massecuite. Crystallization stops when the crystals have reached the desired size. The massecuite is then passed on to a centrifuge to separate the crystals from the liquid before they are dried in a granulator with warm air. The remaining syrup still contains some sugar which is recovered by further crystallization, but this sugar is of lower quality and is generally used to make the mother liquor.

The final molasses is the final syrup, which is centrifuged from the sugar crystals after repeated crystallization. The final molasses still contains a high amount of sucrose and can be sold as beet pulp pellets for animal feed, or it can be further processed to recover more sugar. Tight control of molasses processing is essential to ensure the economic viability of the process.

Instrumentation and installation

Vaisala Polaris™ PR53 Process Refractometers are deployed to implement real-time control at various stages in the sugar production process (see schematic for typical measurement points). This unique digital technology combined with a rugged design delivers highly accurate and reliable measurements for complete process control.

Refractive Index (RI) measurements are based on the angle of refraction of light in the process medium, using an LED light source. A sensor continually detects the critical angle at which the total reflection of light commences, and this has a direct relationship with the Brix value.

Vaisala Polaris process refractometers are compatible with the Indigo platform of smart sensors and transmitters, offering simple plug-and-play technology along with user-friendly interfaces, service, and configuration tools.

In contrast with other measurement methods, the main advantages of Vaisala’s refractometers are that they are not affected by suspended particles, bubbles or colour, and with the option of automatic prism wash with steam or high-pressure hot water, they are not affected by scaling or fouling. From an operational and cost perspective a major advantage is that they are factory calibrated and do not require any routine recalibration or maintenance.

Summary

By enabling real-time control of the process, Vaisala’s inline process refractometers help improve efficiency and product quality, reduce waste, lower costs and enhance sustainability.

Accurate inline Brix/concentration measurements with Vaisala Polaris refractometers provide:

- Increased quality of liquid and crystal sugars

- Precise adherence to recipe

- Assurance that liquid bulk sugar and molasses meet specifications

- Optimized extraction process by minimizing the usage of water for subsequent evaporation

- Energy savings by adapting product flow to the capacity of the evaporators

- Control over the feed juice concentration to meet the capacity of the separation columns

- Interval extension between recovery cycles and prolonged column lifetime

- Monitoring supersaturation for strike control & avoiding spontaneous nucleation

- Implementation of automatic and accurate seeding of the vacuum pan.

Author: Maria Nyman

Maria works as Application Manager with Vaisala Liquid Measurements products that support inline process refractometer measurements in multiple processing industries. Maria holds a Bachelor of Science (B.Sc.) in Environmental and Process Engineering and a Master of Science (M.Sc.) in Sustainable Energy Systems, both obtained from the University of Oulu. Maria is enthusiastic about helping Vaisala customers improve their liquid measurements to optimize resources and improve process control.