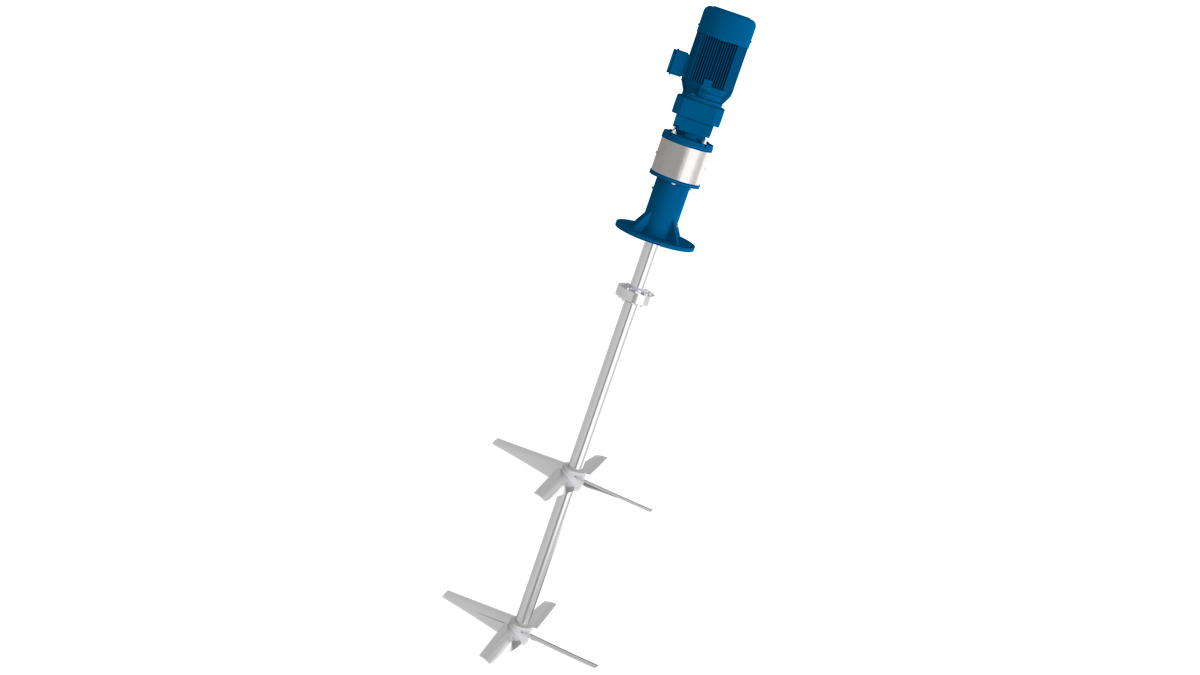

High quality materials, welding, and finishing assure integrity and validation in sanitary, ultra-high purity and hazardous applications. ASME stamping is standard; CE/PED, other certifications available. Options may include mixers, pumps, plumbing/valve manifolds, instrumentation, controls, filters, lifts, heating/cooling systems, CIP, SIP and other features. Fabricated with 316L stainless steel; other alloys such as Hastelloy, finishing levels and coatings are also available. Custom designed complete turnkey skid mounted systems, from 1 to 1000 liters, are offered incorporating blenders, reactors, fermenters, nutsche filter/dryers, extractors, distillation columns, feeders, multiple vessels, control systems, etc. Applications assistance and innovative process equipment design is a company specialty.

About Pope Scientific

Pope Scientific has been at the forefront of manufacturing chemical processing equipment, engineered systems and laboratory apparatus for science and industry. Today Pope is internationally known – with specialized technical expertise in design and manufacture of chemical processing equipment.

Our long history demonstrates how clients have brought both routine and difficult and demanding separation/purification/mixing applications to us to make their solutions a reality…why we are solution driven. Located north of Milwaukee, Wisconsin, in Saukville, Pope has 64,000 square foot manufacturing facility which houses our engineering, construction areas, technical and testing labs, glassblowing facility, shipping /storage and a fully equipped toll processing area.

Pope’s wiped film (short-path) molecular stills and evaporators, fractional column batch and continuous mode distillation systems, hybrid still systems, stainless steel pressure vessels, process vessel systems including reactors, mixing vessels and turnkey liquid processing systems, nutsche filter-dryers, and cryogenic dewar flasks can all be found throughout the world in a wide array of production processing industries, pilot plants, laboratories, universities and institutes.