Application

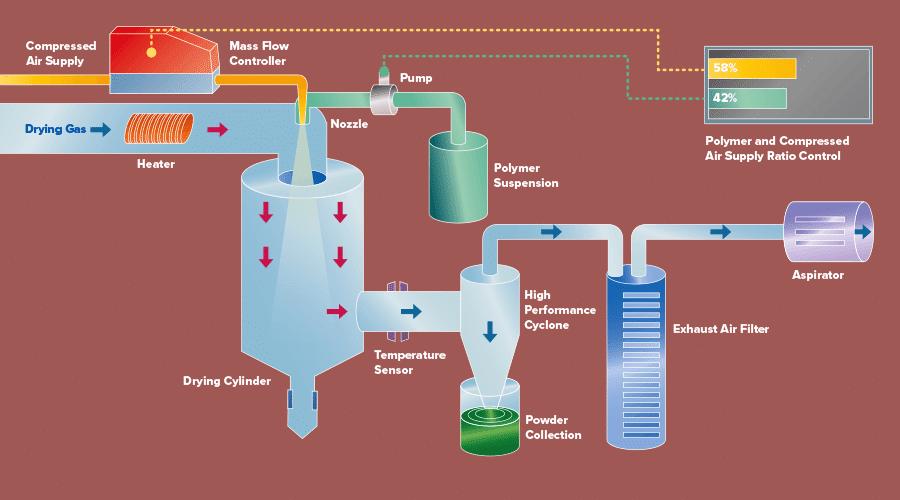

Spray drying is a technological method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals.

A consistent particle size distribution is a reason for spray drying some industrial products such as catalysts. Air is the heated drying medium; however, if the liquid is a flammable solvent such as ethanol or the product is oxygen-sensitive then nitrogen is used.

In most cases the air is blown in the same direction as the sprayed liquid (co-current) and a fine powder is produced. Various technologies are used in the spray drying process: Pressure nozzle atomization, two-fluid nozzle atomization and centrifugal atomization.

Challenge

For most spray drying systems, variable area flowmeters (VA-meters) with manual control valves are used. If inlet pressure prior to the manual valve changes, the gas flow becomes unstable. This creates non-repeatability and non-conformity in particle size of the process.

Solution

MEMS technology of the mass flow controllers (MFCs)provides for a 500ms rapid response. Plug-and-play functionality and no warm-up periods improve user productivity.

Vögtlin MFCs have a unique way of compensating for changes in ambient and gas temperature, which strongly improves the repeatability. The MEMS technology ensures a long-term stability without any drift. The digital MFCs also allow to automate the process with the use of a digital control system.

Vögtlin MFCs have a unique way of compensating for changes in ambient and gas temperature, which strongly improves the repeatability. The MEMS technology ensures a long-term stability without any drift. The digital MFCs also allow to automate the process with the use of a digital control system.

Gas flow readings are taken 3 times per second and can be stored using data logger software. Traceability of production can be guaranteed.

Key Features

- High repeatability & reliability

- High turndown ratio

- Long-term stability

- Short response time

- Safe and fast control

- Compact unit with high-quality components

Interfaces

- Analog

- Modbus RTU

- Profibus DP-V0/DP-V1

- Profinet*

- EtherCAT*

*available from January 2019