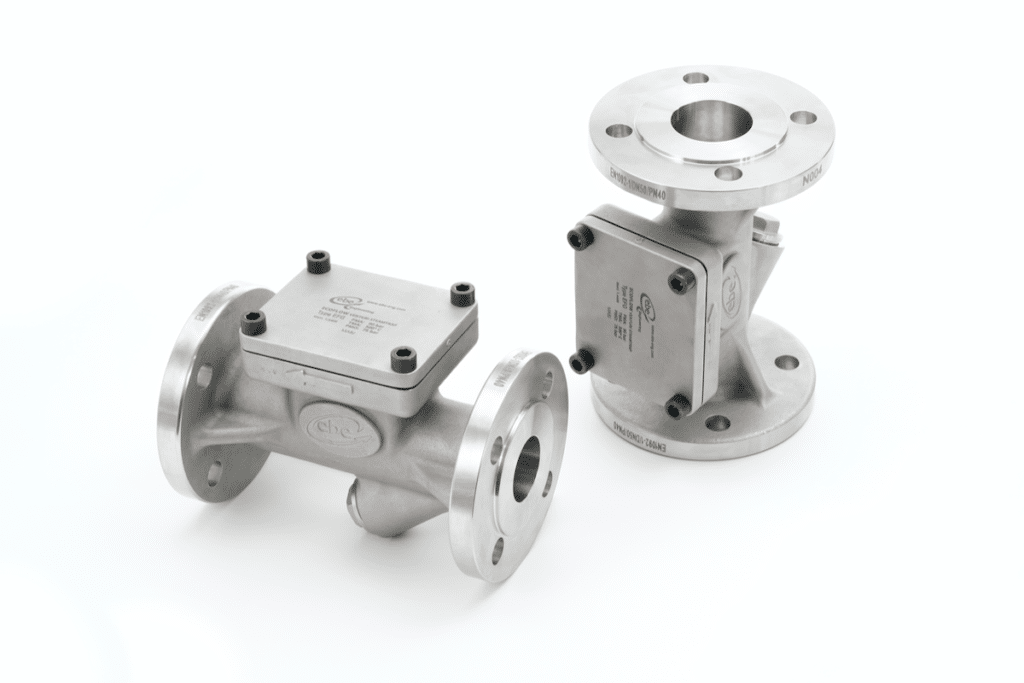

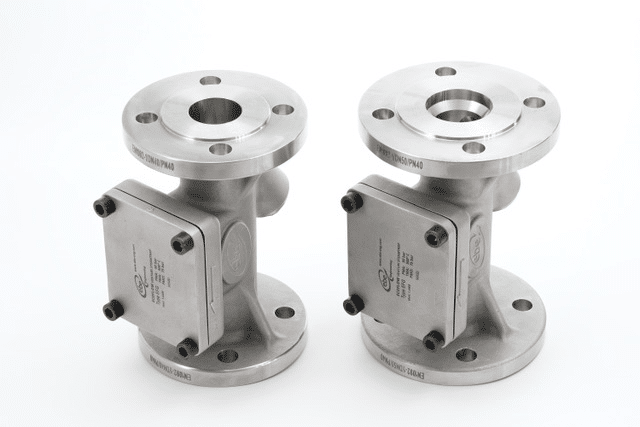

Using the modular concept developed in the smaller flange sizes from DN15 to DN25, the new DN40 and DN50 flanged design allow for maximum flexibility, as larger interchangeable nozzle sizes can be used and achieve higher flow rates (up to several tonnes of condensate per hour).

The DN40 and DN50 are now cast in 1.4408 austenitic stainless steel. This antimagnetic material offers superior resistance to aggressive acidic environments and is ideal for chemically contaminated industrial as well as all other standard environments. Manufactured using precision investment casting which produces an excellent surface finish and dimensional tolerances. The completely homogeneous housing has no weld joints enabling EBE to deliver a product meeting the highest standards of the stringent European pressure equipment directive as well as the AD2000 Merkblatt W0 regulations.

The ECOFLOW Venturi orifice steam trap, from EBE Engineering, is the most advanced Venturi orifice steam trap on the market today. The fully flanged cast housing was designed, developed, and refined using 3D modeling and casting simulation software. Producing a Venturi orifice steam trap to meet the rigorous requirements of today’s steam plant users. Developed on a modular concept, the ECOFLOW Venturi orifice steam trap encompasses a wide range of capacities, from minimal condensate flow requirements o- line drainage and trace heating systems, through to the high flow volumes and variable loads of process heating applications.

EBE Engineering Managing Director, Nigel Egginton is happy to report: “This latest addition to our range gives us a complete product offering that cannot be matched by any other venturi orifice steam trap manufacturer. It has always been our intention to eliminate weld joints and supply fully cast venturi orifice steam traps. The expanded ECOFLOW range enables us to supply all industrial steam users with this exceptional product across the entire range of ISO EN 26554 flange requirements and meet all their process flow needs.”

The unique ECOFLOW venturi orifice steam traps can be used on all steam applications in every type of industry. Improving the overall energy efficiency of steam systems through the innovative venturi technology, and with no moving parts they are effectively maintenance-free. In contrast to traditional mechanical steam traps there are no mechanical sealing faces in the trap to fail and cause steam leakage. With no wear parts, ECOFLOW delivers a permanent solution for all your steam trapping requirements.

The complete range is assembled and available from stock through EBE’s German subsidiary, where all European and global markets are serviced directly.