By following a systematic step-by-step plan, you can easily identify, and repair compressed air leaks, leading to savings of up to 30% on the total energy consumption of the compressed air installation. The cost of repairing air leaks can even be fully recouped within a few days to a few months, after which the financial savings can be enjoyed for a long time to come. Imagine what you could do with the extra money in your budget!

Don’t let compressed air leaks drain your wallet any longer. Stay vigilant, address any compressed air leaks as soon as possible, and avoid unnecessary financial losses. With proper monitoring and maintenance, you can keep your compressed air installation running smoothly and efficiently, while saving money and resources for your business.

Step 1. Look at the downtime consumption

If a factory is not in operation 24/7 and, for example, shuts-down over the weekend, in theory no compressed air is used during that time. This is a good moment to take a look at the compressor room. If the compressors still kick on frequently over the weekend, one can assume that there are serious leaks in the factory that cost the company a lot of money!

Step 2. Quantify compressed air leakage with a bleed test

To quickly get a first impression of the degree of leakage, a so-called bleed test can be carried out. For this purpose, the factory must be shut down and the compressed air system must be pressurized. After switching off the compressor, the time it takes for the compressed air system to drop by, for example, 29 PSI, is then measured. The faster the pressure drop, the larger and/or more numerous the leaks. It is hard to imagine a better starting signal for tackling leaks.

Step 3. Identify individual leaks

Compressed air leaks can occur anywhere in the factory. They are caused by broken couplings and seals, damaged threads of pipe connections, cracked or broken hoses, incorrectly selected and/or installed parts or rusted pipes. But leaks also occur due to normal wear and tear. In the shaft and piston seals of pneumatic cylinders for example and in commonly used couplings. always have one thing in common: they make noise. Sometimes a clear hissing sound is audible, but the sound can also be beyond the human hearing range. In that case, the use of ultrasonic leak detectors and directional microphones is the solution. This allows immediate detection of both the size and exact location of compressed air leaks. By identifying and categorizing leaks based on their nature and size, it is possible to prioritize the most costly and easiest to repair leaks.

Step 4. Install flow- and pressure meters

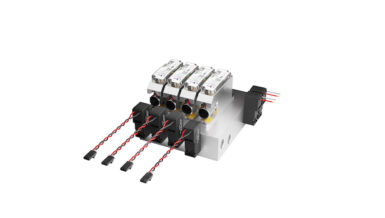

In addition to regularly carried out leakage audits, 4-in-1 flow meters can be installed. These measure both flow and pressure and thus provide useful, up-to-date information about the behavior of the compressed air system as a whole and/or in specific parts thereof. These 4-in-1 flow meters can be mounted directly behind each compressor in the pipe(s), but also in the main pipe behind the buffer tank and in branches that provide the compressed air for each production department. A sudden increase in flow rate may indicate errors in one or more machines or systems, or may be caused by a sudden increase in leaks. This can also cause an immediate drop in pressure and even endanger the functioning of the entire factory. After all, every system powered by compressed air requires a minimum operating pressure. If the pressure becomes too low, machines can fail. Measuring both flow and pressure therefore also reduces the risk of production failure.

Step 5. Make leak investigation part of regular maintenance

Leaks occur not only due to sudden damage, hose breakage and installation errors, but also due to normal wear and tear. This means that the situation can change from day to day. Therefore, keep a continuous eye on compressed air consumption compared to a previously determined basic consumption level. Especially in the event of deviations, the installation immediately has to be checked for leaks. Also do this periodically by making leak investigation a permanent part of planned regular/periodic maintenance.

Step 6. Encourage the right collaboration and training

Reducing leaks requires collaboration between different people and departments within a factory. Operators play a crucial role here because they are often the first to discover leaks. After all, they are continuously present in the factory. It is therefore essential to train operators in recognizing leaks and to properly inform them about the costs and consequences that leaks can cause. Then everyone will understand the importance of reporting leaks immediately to the maintenance department for quick repair.

Step 7. Apply real-time compressed air monitoring

By measuring the compressed air and energy use of compressed air systems in real-time via an energy management system such as VPVision, you know the current compressed air- and energy use and therefore the costs at any time. After optimizing the system by eliminating leaks and adjusting the pressure, a new basic consumption level has been determined. In case of sudden deviations, the system will automatically trigger an alarm, after which the cause can be immediately identified. For example, a strong drop in pressure and a rapidly increased compressed air consumption may indicate new leaks and malfunctioning machines and systems. This is a good time to conduct another leak audit and fix any leaks found. Continuous monitoring will minimize leakage.