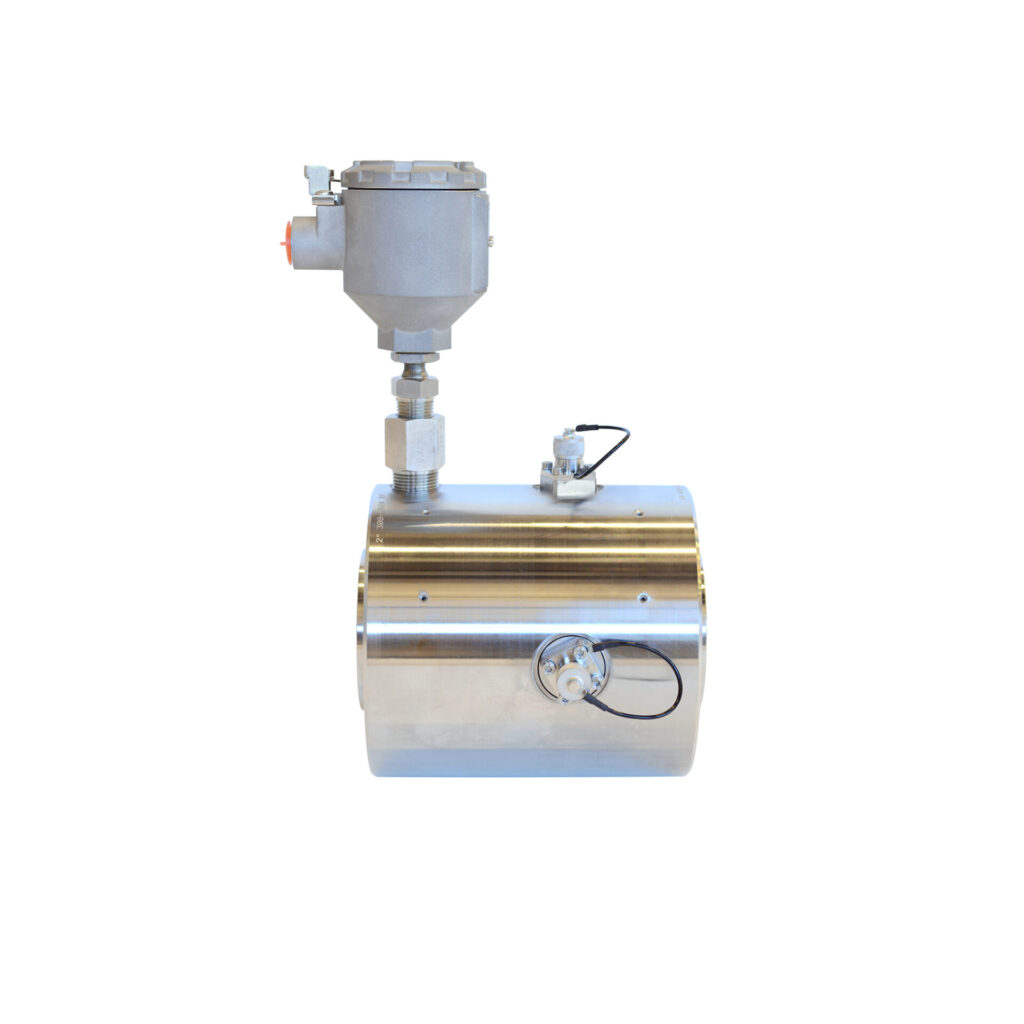

The Roxar Watercut Meter uses a full-bore microwave resonance measurement method, an approach that ensures representative readings across the entire fluid stream. Unlike probe-style sensors that only sample a portion of the flow, this technology performs at the highest level without assuming a uniform flow profile across the entire pipe bore.

Advanced Features for Dynamic Environments

Emerson’s Roxar Watercut Meter includes several patented and advanced feature options designed to improve measurement integrity and ease of use. Here are two examples:

- AutoZero Technology – This feature uses real-time density input (from a Coriolis meter or densitometer) to automatically recalibrate the measurement baseline when oil density shifts – common during production changes or well testing. It eliminates the need for manual intervention, reducing operator burden and increasing confidence in measurement results.

- Snapshot & Lab Sample Correlation – Field personnel can capture a “snapshot” of process conditions at the exact moment a lab sample is taken. This enables direct correlation between lab analysis and meter data, ensuring consistency in validation, calibration, and performance tracking.

Key Benefits with the Roxar Watercut Meter

Emerson’s Roxar Watercut Meter stands out for many reasons and some key aspects are:

- High Accuracy and Sensitivity – Full-bore, high-quality measurement, reliable even in unstable flowing conditions, and sensitive down to 50ppm.

- Operational Flexibility – Performs across a wide range of water cut applications, including heavy oil and condensate.

- Digital Intelligence – Advanced features enhance meter capabilities.

- Ease of Use – No moving parts, a drift-free measurement approach and no need for dynamic calibration for set-up or continued high-performance makes it a low maintenance instrument.

Combined with Emerson’s global service network, the Roxar Watercut Meter provides a robust solution for operators aiming to improve measurement performance reliability.

Applications Suitability

The versatility and robust nature of the Roxar Watercut Meter makes it ideal for a wide range of operational scenarios.

- Upstream – Applications including being part of a test separator solution, production separator and fiscal metering skid all call for water cut metering instrumentation. A water cut meter may be installed on the liquid leg of a two-phase separator or the oil leg of a three-phase separator, for example.

- Midstream – It is typical that oil will change hands, with midstream companies taking responsibility for transportation to refineries for processing. Custody transfer measurement is required, as well as measurement at onloading for transportation, with water cut measurement being required and a key control point.

- Downstream – Refining, distributing and selling crude oil are downstream activities. Offloading typically requires water cut measurement, and there are water cut measurement points within refineries as well.

Explore the technology that’s redefining watercut measurement and elevate your operational accuracy today.

The Roxar Watercut Meter Enables Process Efficiency at a Large Refinery Site in Tianjin, China

A large refinery in China needs to monitor and analyze crude oil and water content to the desalter. The customer previously had no measurement check and was relying on supplier’s metering data regarding the quantity and quality of the crude oil being transferred. Emerson provided a mass and water cut metering system at the refinery, enabling the customer to measure, monitor and analyze the crude oil variability. The metering system utilizes the Roxar Watercut Meter and the Micro Motion™ ELITE Peak Performance Coriolis Flow and Density Meters.

The water cut meter provides highly accurate and sensitive water cut measurement. The Coriolis meter provides mass flow rates giving control of total liquid rates, as well as providing live density measurement input to the water cut meter. This enables the water cut meter to adapt automatically to any changes in density and maintain measurement quality on a continuous basis using the AutoZero feature.

With this solution, Emerson supports the refinery in achieving:

- Continuous real-time measurement and insight into crude oil analysis

- Unmatched sensitivity and long-term stability using the Roxar Watercut Meter

- Increased profits due to optimized production and reduced corrosion damage to equipment

Written by Kelda Dinsdale, Product Marketing Manager.

Read the full case study to see how Emerson’s advanced technology delivers measurable results.