Today, automated mass flow control is emerging as a practical and scalable alternative. By directly measuring and adjusting flow in real time, Mass Flow Controllers (MFCs) are helping engineers move beyond estimation and manual tuning into a new era of accuracy, reliability, and efficiency.

The Problem with Pressure-Based and Fixed Flow Control

Traditional gas delivery systems often use pressure regulators, restrictors, or manually set valves to approximate flow. While simple, these methods assume stable conditions and consistent system behavior—assumptions that rarely hold true in dynamic environments.

Even minor changes in tubing, temperature, or partial clogging can significantly alter flow rates. Without real-time feedback, these deviations go undetected, leading to inconsistent performance, increased maintenance, and wasted resources. Manual setups also require frequent intervention and lack the responsiveness needed for modern systems.

What Makes MFCs Different?

Mass Flow Controllers use closed-loop control to continuously measure and adjust gas flow in real time. Unlike pressure-based or fixed systems, MFCs respond dynamically to changes in system conditions, ensuring consistent delivery regardless of wear, clogging, or environmental variation.

This shift from estimation and manual control to automated feedback enables tighter process control, faster diagnostics, and simplified system design—without the need for complex redesigns.

Real-World Applications Across Industries

1. Analytical Instruments

In analytical systems, stable gas flow is critical for consistent performance and reliable data. Many setups still rely on pressure-based control, which can lead to flow instability and degraded results. By integrating compact MFCs, OEMs have achieved real-time flow feedback without redesigning their systems—resulting in improved reproducibility, better data quality, and reduced downtime.

2. Vacuum-Based Processes

In vacuum applications, inert gas is often used to purge or clean systems. Fixed-flow setups can lead to overuse, driving up operating costs and increasing the volume of gas that must be treated. By implementing variable flow control with MFCs, operators can optimize gas usage, reduce waste, and improve sustainability—without compromising process integrity.

3. Bioprocessing

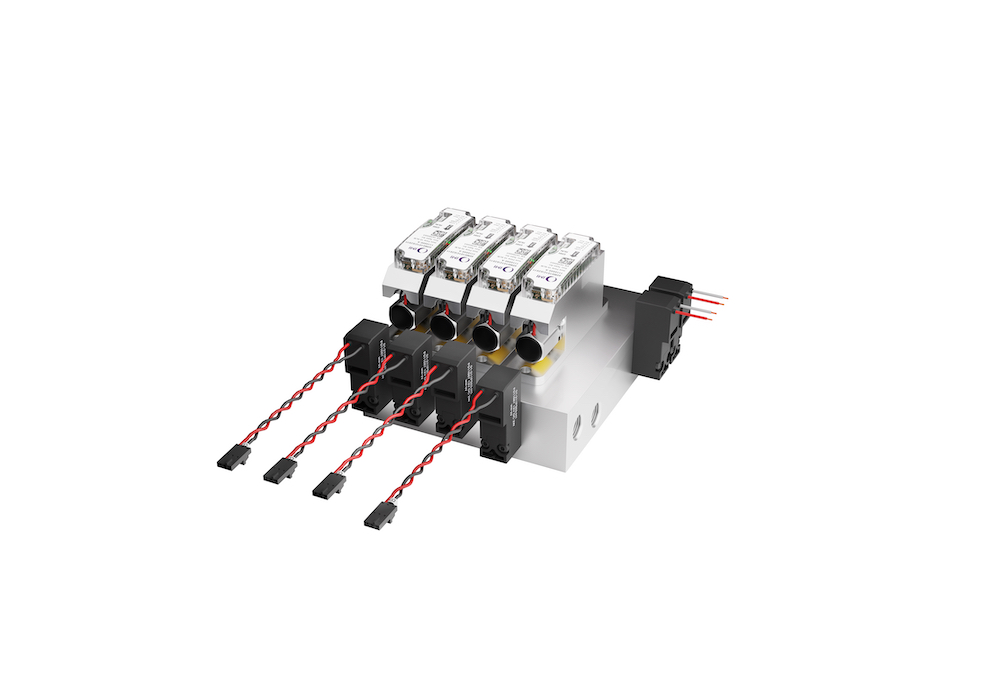

In bioreactor systems, gas control assemblies tend to be bulky, leak-prone, and time-consuming to assemble. Replacing multiple components with an integrated MFC and valve manifold can reduce system size by 70%, cut leakage risk tenfold, and simplify scaling for different reactor volumes.

4. Plasma Cutting

In many plasma cutting systems, gas flow is inferred from upstream pressure rather than measured directly. This indirect method provides no visibility into actual flow conditions and can mask issues such as line restrictions, leaks, or nozzle clogging. These disruptions often go undetected until they degrade cut quality or cause part defects, leading to costly rework or scrap.

Integrating mass flow controllers (MFCs) enables direct control of gas flow in real time. This approach ensures accurate and repeatable gas delivery across varying operating conditions, resulting in improved process stability, cleaner cuts, and higher overall yield.

The Broader Impact: Precision Enables Progress

Across these applications, the benefits of automated, real-time flow control are clear:

- Performance: Stable, reproducible flow improves data quality and process reliability.

- Efficiency: Less gas wasted, fewer scrapped parts, and reduced maintenance.

- Sustainability: Lower emissions and abatement costs through optimized gas usage.

- Simplicity: Integrated assemblies reduce component count, leak points, and engineering effort.

Key Takeaways

- Pressure ≠ flow. Estimating gas delivery introduces risk and inefficiency.

- Manual setups lack adaptability. Automated control responds in real time.

- MFCs provide measurable performance gains across diverse applications.

- Applicable across analytical, vacuum, bioprocess, and cutting systems.

Conclusion

As industries demand more precision, automation, and accountability, gas control systems must evolve. Real-time flow control is no longer a niche innovation—it’s a practical upgrade that delivers measurable value. For engineers still relying on pressure-based estimation or manual tuning, the question is no longer “if” but “when” to make the switch.