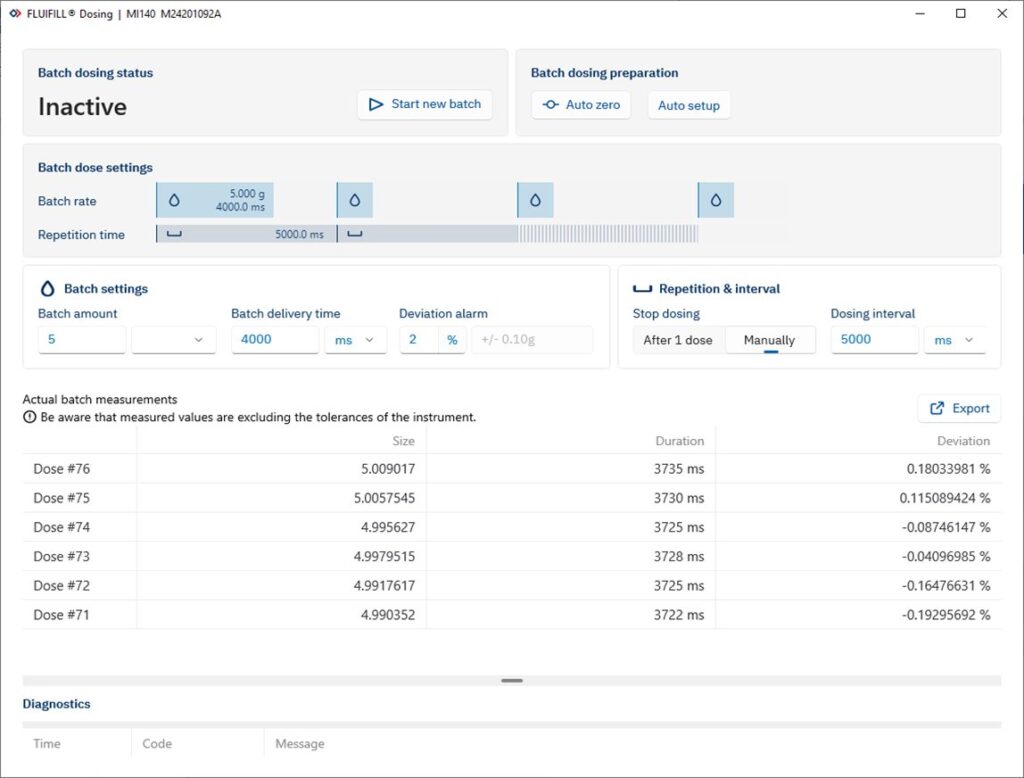

Bronkhorst’s FLUIFILL® technology offers a solution tailored for the demands of modern production. This firmware-based innovation enables fast, accurate, and straightforward batch dosing, integrating seamlessly with Coriolis or ultrasonic flow meters. The result? Reliable dosing performance without the need for a PLC, making automation accessible even for smaller operations. FLUIFILL® adapts to real-time process conditions, handling a wide range of dosing durations—from milliseconds to several seconds—and supporting both PID-controlled and on/off valves or pumps. Its instruments automatically learn and adjust to their environment, ensuring precise filling from the start while minimizing waste and maximizing traceability.

Why does this matter for fluid handling professionals?

- Versatility: FLUIFILL® isn’t just for food and beverage. It’s equally effective in pharmaceutical vial filling, hygienic product dosing, and even battery electrolyte filling.

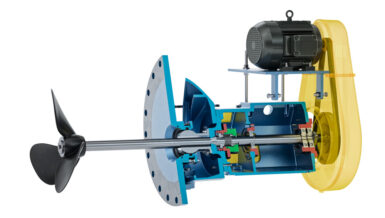

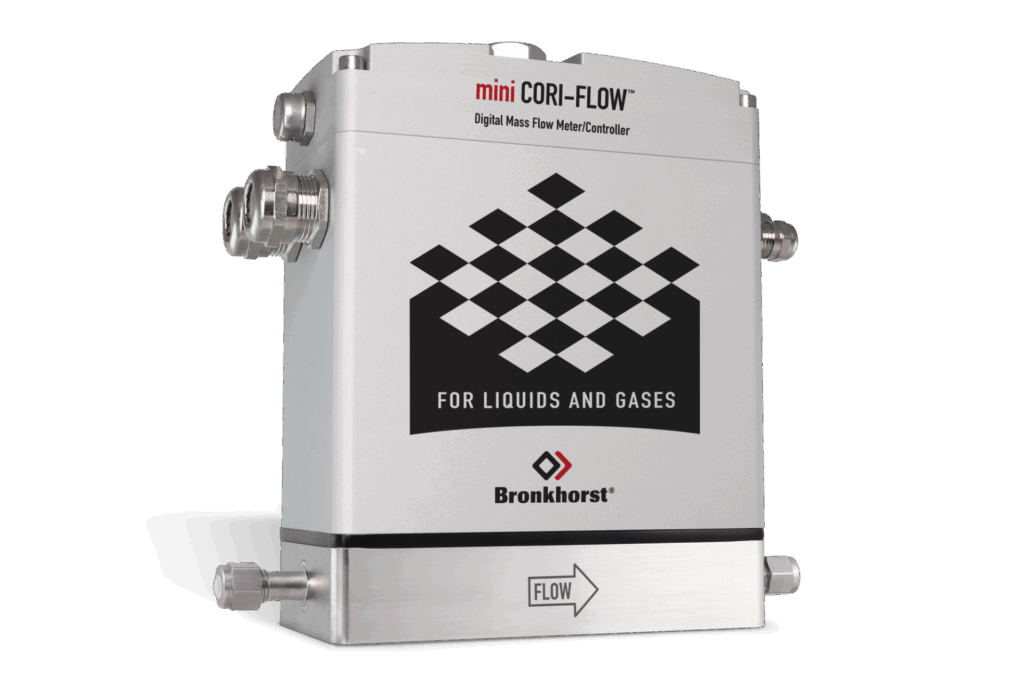

- Integration: Bronkhorst’s mini CORI-FLOW and ES-FLOW series are designed for accurate measurement and control of low liquid flow rates. The Coriolis principle ensures high accuracy, independent of fluid properties, while ultrasonic transit-time technology offers repeatability and minimal pressure drop—ideal for clean-in-place systems.

- Digital Transformation: With Bronkhorst FlowSuite software, users can easily configure and monitor dosing systems. The instruments support a wide range of fieldbus communication protocols, ensuring smooth integration into automated setups.

Sustainability and Efficiency

FLUIFILL® helps manufacturers meet industry challenges like sustainability, traceability, and production flexibility. By replacing manual dosing with digital control, it reduces waste, improves reproducibility, and provides instant warnings about process failures. Its large turndown ratio means fewer spare instruments are needed, supporting lean inventory strategies.

Ready to optimize your fluid handling process?

Bronkhorst’s specialists are available to help you implement FLUIFILL® for your specific needs—whether you’re producing thousands of bottles per hour or handling delicate, high-value ingredients. For more information, visit Bronkhorst’s FLUIFILL knowledge base.