Marshmallow production differs from most candy production in that its density is significantly reduced by the addition of air.

The production process involves mixing air and sweeteners such as corn syrup, sugar, and dextrose with emulsifiers, water, and gelatine to give the marshmallow mixture a fluffy consistency.

Challenges

In addition to the ingredients, the amount of air injected plays an important role in the consistency and quality of the marshmallow mixture.

The air flow must be precisely controlled by the process and adjusted to the amount of marshmallow mixture.

This ensures consistent quality of the final product.

Solutions

I. Measurement of the marshmallow mass flow

The TRICOR Coriolis mass flow meter (TCM 028K) provides precise data on the mass flow of the marshmallow mixture after the process tank, with an accuracy of 0.3–0.4%.

This information is used to control and stabilise viscosity, flow rate, temperature, and pressure via the PLC system, ensuring consistent product quality.

Coriolis mass flow meters offer excellent response behaviour and high production accuracy, which reduces both the need for multiple production controls and the overall development and maintenance costs of the production line.

Fluid/mass: Marshmallow raw mass

Flow rate: Depends on the capacity of the production line. For our application, the maximum value is 15 kg/min. and the minimum value is approximately 1.5 kg/min.

- Pump pressure: 5 bar

- Temperature: Up to 100 °C

- Density: ~17 kg/m3

- Viscosity: approx. 200–2000 Cp at 80 °C

Marshmallows come in two varieties: non-grainy and grainy.

For both varieties, a controlled amount of clean air is essential to achieve the desired texture. Too much or too little air during production changes the consistency and appearance of the marshmallow as well as its physical volume.

Therefore, the air flow during production must be precisely controlled.

As soon as the raw marshmallow mixture leaves the tank, the quantity conveyed must be measured precisely to ensure consistent quality right through to the end product.

A medium-sized marshmallow production line produces 20–25 tons in 24 hours.

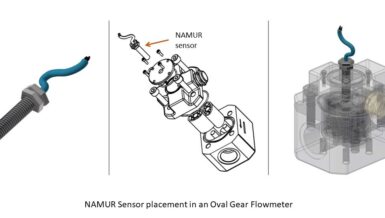

II. Monitoring the air flow into the marshmallow mixture

Vögtlin’s thermal mass flow controllers offer higher precision and faster response times.

The application requires an accuracy of at least 1% of the volume flow. Vögtlin’s MEMS sensor technology offers an accuracy of 0.5% with a fast response time.

The flow rate of clean air depends on the production capacity – in this case, the maximum value was around 70 ln/min.

Gas: Clean air

Flow rate: Depends on the capacity of the production line. For our application, the maximum value is around 70 ln/min

- Delivery pressure: 10 bar

- Inlet pressure: 8 bar

- Outlet pressure: 7 bar

- Temperature: 20–30°C

Delivered Product

- TRICOR Coriolis mass flow meter TCM 028K

- Thermal mass flow controller from Vögtlin