Did you ever wonder why the wind in the Northern hemisphere mainly blows in a west/east direction during a low-pressure system? The answer lies in the earth’s rotation on its axis, and the higher speed at the equator compared to the poles. This rotation takes the wind along and forces it to blow mainly in a west to east direction in the Northern hemisphere. It was the French scientist Gaspard-Gustave de Coriolis who discovered the effect that flowing air experiences a lateral force, which named after him: the Coriolis effect. The first take home message is: the Coriolis effect explains the deflection of flowing air moving in a rotating system. In fact, the Coriolis effect is a mass inertia effect.

Coriolis flow sensors

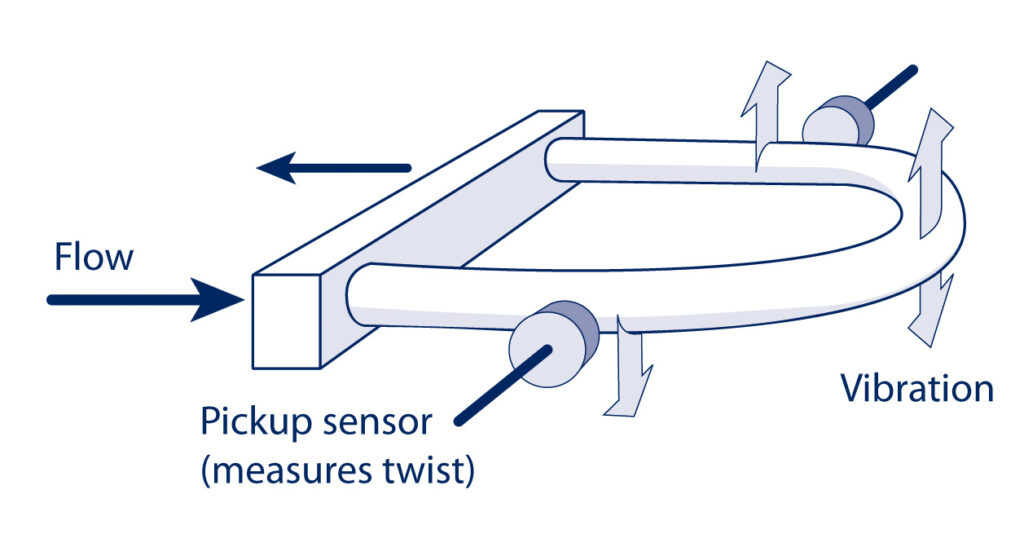

This Coriolis effect found application ‘down to earth’ in mass flow measurement of gases and liquids. To this end, the fluid is forced to flow through a vibrating tube. In the Coriolis flow sensor, an actuator allows a tube to vibrate continuously around its natural frequency. Sensors positioned along the tube measure the deflection of this vibrating tube in time. Without a fluid flowing through the tube, both sensors measure the same deflection at the same moment in time. However, when a gas or liquid flows through the tube, the mass of this fluid poses an additional twist to the tube due to the fluid’s inertia. The difference between the two, known as the ‘phase shift’, is a direct measure of the mass flow through the tube. This phase shift is proportional to the mass flow rate: a larger phase shift is the result of a higher mass flow rate.

Mass flow meters according to the Coriolis effect do even more. While phase shift is a measure for mass flow rate, the vibration (natural) frequency is a measure for fluid density. The density of a fluid affects the vibration frequency of the tube: denser fluids vibrate with a lower frequency than less dense ones. The fact that one device can measure the mass flow as well as the density illustrates the versatility of a Coriolis flow meter.

Challenges

With Coriolis instruments, the sensor tube is set into vibration by an actuator. In the case of external vibrations of about the same frequency, this could interfere with the measurement. For example, trains in the surroundings, air conditioning or other machines in the building itself. Identifying these external vibration sources is a first step to minimising their effects. This can for instance be done by moving the Coriolis flow meter to a less vulnerable place, by rotating the device, by using a (bigger) mass block, decoupling using dampers and/or flexible tubes instead of piping.

Best choice

A Coriolis-based mass flow meter is particularly suitable when you want to measure the mass flow of varying or unknown gas or liquid mixtures or for measuring supercritical gases. Besides measuring direct mass flows which eliminates inaccuracies due to the physical properties of the fluid, these devices are highly accurate and have a high repeatability. The Coriolis flow meter is the ultimate flexible, reliable and extremely accurate flow meter. Interested if Coriolis flow meters also could be applied for your challenging flow measurement or dosing application?

On the following webpage you will some interesting stories from customers in the biotechnology, food and pharma markets ->