Choosing a proper flow meter for technical gases is essential to gain correct measurement data and information. It prevents making decisions on inaccurate data and it can save you a lot of money. VPInstruments offers flow meters for multiple inert industrial and technical gases, like nitrogen, CO2, oxygen, argon, helium, and special gas mixtures, which are used in packaging and welding applications. Make sure you answer the questions below to find the right gas flow meter for your application and situation.

1. What is the application?

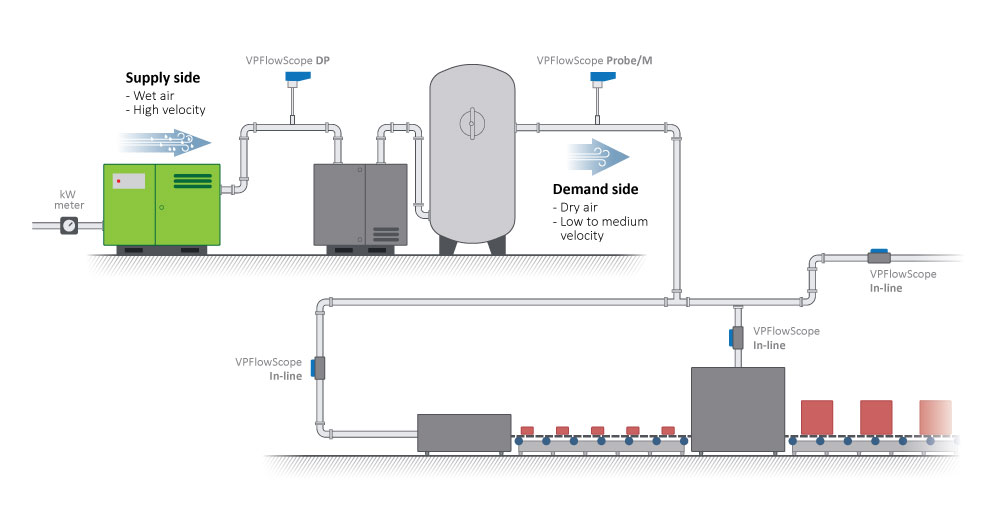

Process conditions, location, and purpose of your measurement all tie into the same base principle: it impacts the selection of the measurement principle. There are several technologies that you can use to measure mass flow of gases. Two technologies which are commonly used are thermal mass flow and differential pressure. Thermal mass flow meters possess a wide turndown ratio with which you can measure almost 100% of your consumption. Because of their large measurement range, you will detect even the smallest leakages of inert gases. So why not always choose a thermal mass flow meter? If the gas is polluted or wet, a thermal meter is not the best option. In that case it is better to choose a meter with a differential pressure flow sensor. A thermal mass flow meter measures dry air from 0.5 to 150 m/sec (0 to 500 sfps). A differential pressure meter 20 to 200 m/sec (65 to 650 sfps) and is therefore not suitable to measure leakages. The ratio between the high and low flow is called “turndown ratio”. So, for thermal mass flow meters this is typically 1:300, whilst for differential pressure flow meters the turndown ratio is 1:10.

2. Size of the pipe and model-type flow meter?

There are two commonly used types of flow meters for measuring flow of inert gases: in-line and insertion type. Compared to the in-line meter, an insertion type flow meter has the benefit that it can be used for various pipe sizes, and it can be inserted under pressure when using a ball valve. Even an insertion point can be created under pressure by using a hot tap drill and hot tap saddle. However, there is a limit to the minimum pipe size for using an insertion type flow meter. Below 2” the field accuracy will be less due to the blockage effect: the sensor blocks a part of the pipe area, affecting the air velocity around the sensor. This effect increases significantly below 2 inch. In-line flow meters are more cost effective compared to insertion type flow meters, this applies for sizes up to 2”. In-line flow meters have a very high field accuracy, especially when using in- and outlet tubes of the supplier. There is one downside to the in-line meter. Unless the flow meter is installed in a special bypass, the process needs to be stopped (locally) when installing an in-line flow meter. This is also true when you want to recalibrate your flow meter.

3. What is the required accuracy and calibration?

For high accuracy, we strongly recommend selecting your flow meter that is calibrated with the specific technical gas. When low accuracy is required, a gas conversion factor can be used as this is more cost effective compared to a specific gas calibration. Be aware though that its accuracy can differ at different pressures and temperatures. In particular for helium, we strongly advise calibrating with real helium gas, at the system design pressure, as the conversion factor varies a lot over the pressure and temperature range. VPInstruments can calibrate your flow meter for CO2, nitrogen, helium, Corgon, argon and other industrial gases.

4. General conditions and installation location?

Local conditions can impact the reliability and the lifetime of the flow meter. For instance, vibration can cause your insertion flow meter to move slowly out of position (when not properly mounted). Direct sunlight can heat up the electronics too much where it will shut down. Long exposure to excessive temperatures may even cause permanent damage. Answer the following questions to describe these conditions and check the specifications of your flow meter consequently:

- Do you install the meter indoors or outdoors? Consider installing an enclosure for the outdoors flow meter to protect it from rain and direct sunlight.

- What is the ambient temperature?

- What is the gas temperature?

- Will there be exposure to dust, chemicals (vapor, liquids, or powder) or other impurities?

- Are there other relevant ambient conditions to consider?

To get accurate measuring results, you also need to know the available straight pipe run and the preferred meter position. Straight run represents the pipe length without elbows, valves, and bends. The straight run requirements are based on laws of dynamic physics, and they are generally accepted as the standard. Depending on the pipe and upstream/downstream objects in the pipe, you will need an upstream of 20*D 1 till 40*D 1 upstream length and a 5*D 1 till 10*D 1 downstream length ( 1 =inner diameter). Read more about the piping tables. Please read this article to determine the required straight run for your flow meter.

5. Types of readout

There are roughly three ways to display the flow meter data: a local display right on the flow meter, displaying the data on a central building management system (BMS), and/or using a datalogger. All options come with their own requirements and their commercial impact. Especially when connecting your flow meter to a BMS or energy management system, proper investigation of the best turnkey solution can potentially save you a lot of money, time, and hassle.

Many flow meters are using an 4.20 mA output to readout their parameters. A proven and reliable solution, but often there is just one measurement parameter available on this output. VPInstruments’ offers 4-in-1 flow meters, measuring mass flow, pressure, temperature, and total flow simultaneously. In that case, a protocol like Modbus RTU is provided to read out all parameters at once. Using Modbus does require an expert to prevent costly mistakes during installation.

With industry 4.0, Ethernet is an upcoming standard. Ethernet has the benefit that it can potentially save you a lot of money on cables, when you can use the existing network infrastructure of the plant. Pricing of cables and their installation is often overseen, where it can be more expensive than the price of the flow meter all together.

6. Required certificates, documents, or tests?

The final thing you want to ensure is the paperwork. Do you need any certificates, documents, or tests? Also think of cleaning requirements. For example: for some oxygen applications, a special degreasing service is required for the flow meter. Always check what applies to your specific situation.