Customer need

A leading North American energy infra-structure company wanted to optimize operations in the unmanned pumping stations of a crude oil pipeline in order to largely prevent unforeseen failures.

This was to be achieved by measuring and analyzing the operating conditions of the mechanical seals using sensors. Especially, the temperatures of the sliding parts and the pressure in the seal chamber should be constantly monitored to prevent seal damage and increase MTBR (Mean Time Between Repair).

In addition, on-site maintenance should be minimized by setting up a location independent monitoring.

Seals and sensors must be able to withstand the extreme operating and ambient conditions at all times.

Existing seals should be retrofittable and data transmission should function independently of the seal.

Project scope

EagleBurgmann was able to completely satisfy the requirements with the newly developed Smart Seal Solution.

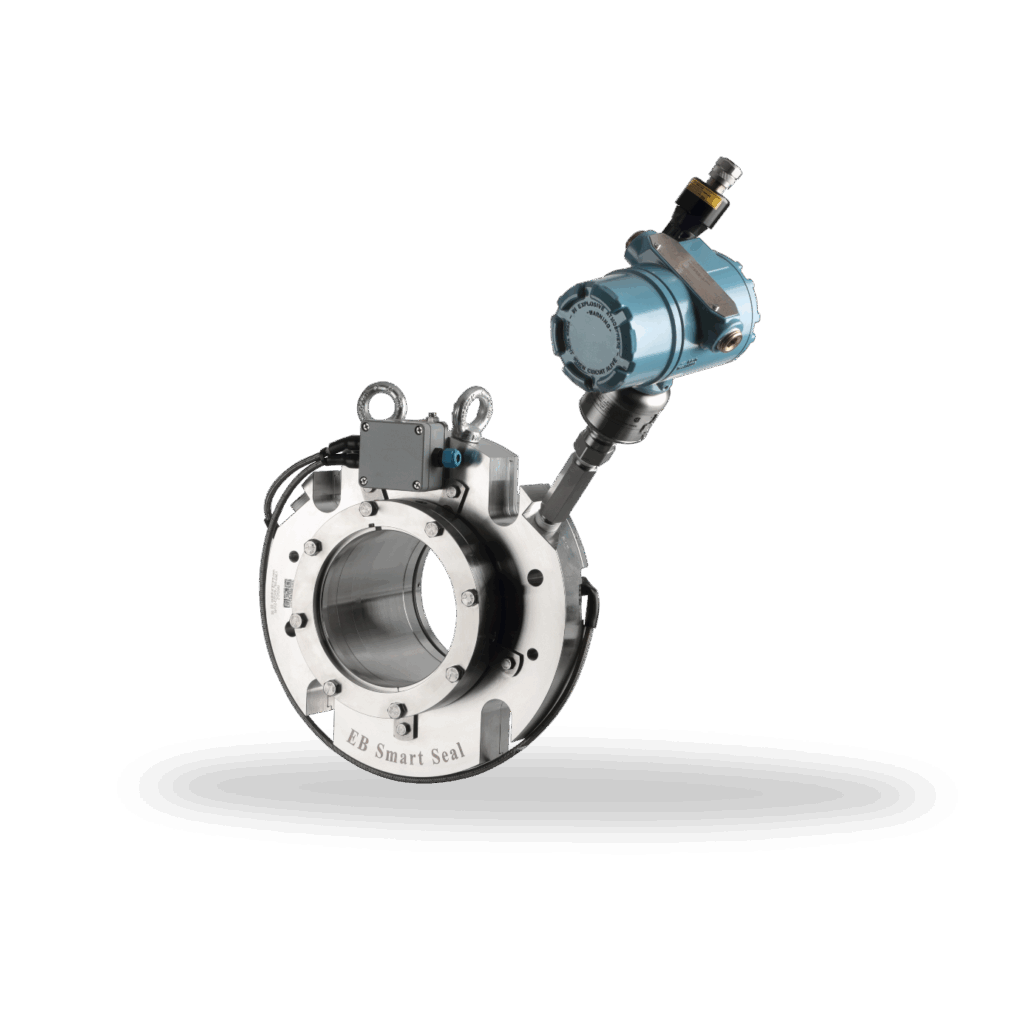

For a test run, four individual high pressure seals with the expansion of the EB Seal Monitoring Kit were installed. The seals are custom-made solutions based on the SH series, which is designed for extreme requirements. The customized sealing solution is designed for shaft diameters from 140 mm to 155 mm (5.511” to 6.102”) and can withstand a suction pressure of up to 100 bar (1450 psi) dynamic.

As a digital solution for condition monitoring, the EB Seal Monitoring Kit enables the continuous collection and transmission of seal data to an application that can be called up online.

The installation and commissioning in the pilot project were successful. The seals were installed during a regular seal replacement in one of the pump stations of the pipeline.

The sensors reliably transmit high-quality data to the cloud, which is regularly evaluated by EagleBurgmann Support.

Retrofitting existing seals with the EB Seal Monitoring Kit is possible by means of special production and corresponding engineering effort. For future applications, the seal series is being expanded to allow access to a wide range of digital monitoring solutions.

The pipeline operator is highly content with the first results of the pilot project and is already contemplating equipping further seals of the same and other pipelines with EB Smart Seal Solutions.

“Reduction of downtimes and service calls”

Highlights

To optimize the operating processes in a crude oil pipeline, a leading North American energy infrastructure company commissioned EagleBurgmann to integrate an intelligent condition monitoring concept for the mechanical seals used.

With customized EB sealings solutions and the EB Seal Monitoring Kit, a reliable data basis was created for comprehensive analyses and the derivation of suitable measures.

Thanks to EagleBurgmann’s expertise, a sustainable solution was created that minimises emissions.

Solution

Pressure and temperature sensors in the seals record data and transfer it to an external transmitter.

The system architecture uses the IT industry standard WirelessHART – a wireless sensor network technology with all explosion protection certifications that enables large areas to be covered and a high level of transmission security thanks to its mesh-like topology.

The data is sent to the myEagleBurgmann cloud via an IoT gateway using LTE and can be accessed graphically visualized and clearly structured in the EB Smart Product Application.

The cloud solution guarantees data protection and data security in accordance with ISO 27001.

Data storage for up to one year allows comprehensive analyses.

The integrated Instant Service application enables supplementary documents to be filed, providing additional support for maintenance management.

“Minimized emissions thanks to elimination of control runs”

Results

The energy infrastructure company benefits from a consistent, reliable data basis that can be used to optimize the process conditions in the pipeline’s pump stations, thereby helping to increase the MTBR (Mean Time Between Repair) and the service life of the seals.

The improved scheduling of downtimes leads to an increased predictability of operations.

Service calls could be reduced.