Titan’s portfolio of flowmeter products are engineered to meet these challenges delivering accuracy, reliability and durability in extreme operating conditions. This reliability reduces downtime and maintenance costs while supporting strict regulatory compliance in chemical manufacturing and dosing. Designed with chemically resistant materials such as PEEK, PVDF, and stainless steel, Titan’s flowmeters are ideally suited for laboratory, pilot plant and full-scale production processes and applications using handling corrosive fluids, ultra-pure water and high-viscosity liquids.

Titan’s comprehensive range of flowmeters include:

- 800, 900 & 1000 series Turbine Flowmeters – Compact and highly accurate, ideal for dosing and dispensing applications. Chemically resistant options make them suitable for aggressive chemicals and cooling systems.

- Atrato Ultrasonic Flowmeters – Non-intrusive technology with no moving parts, providing low maintenance, high accuracy measurement across a wide dynamic flow range. Perfect for continuous monitoring of both clean and aggressive fluids.

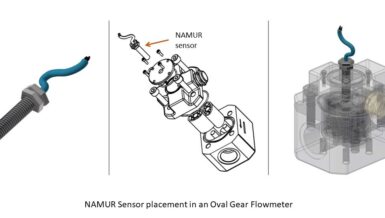

- Oval Gear Flowmeters – Designed for viscous fluids providing high-precision and long life, offering excellent repeatability in challenging chemical applications.

- Industrial Flowmeters – The durable Industrial Process Atrato and high-pressure oval gear meters meet the demands of large-scale processes.

Seamlessly integrating into automated control systems, Titan flowmeters and instrumentation deliver real-time, dependable data that helps operators maintain efficiency, ensure product quality, and comply with stringent regulatory controls.

Trusted worldwide, Titan Enterprises’ flow measurement solutions give chemical engineers the confidence to handle even the most aggressive and sensitive applications. By combining robust construction with proven accuracy, Titan’s flowmeters provide the assurance needed for safe and efficient chemical processing.

Further Information:

https://flowmeters.co.uk/selecting-specifying-liquid-flow-meters/