Among other industries, Scymaris offers its services to pharmaceutical companies and government agencies, as pharmaceuticals can have significant environmental implications and therefore require an environmental risk assessment. Part of this process involves aquatic ecotoxicology studies using seawater. Due to the facility’s proximity to the sea, it sources this water directly and stores it in two large tanks for added resilience. However, this creates a harsh and corrosive environment which puts stress on the pipes and instruments required to transport the seawater to the lab spaces.

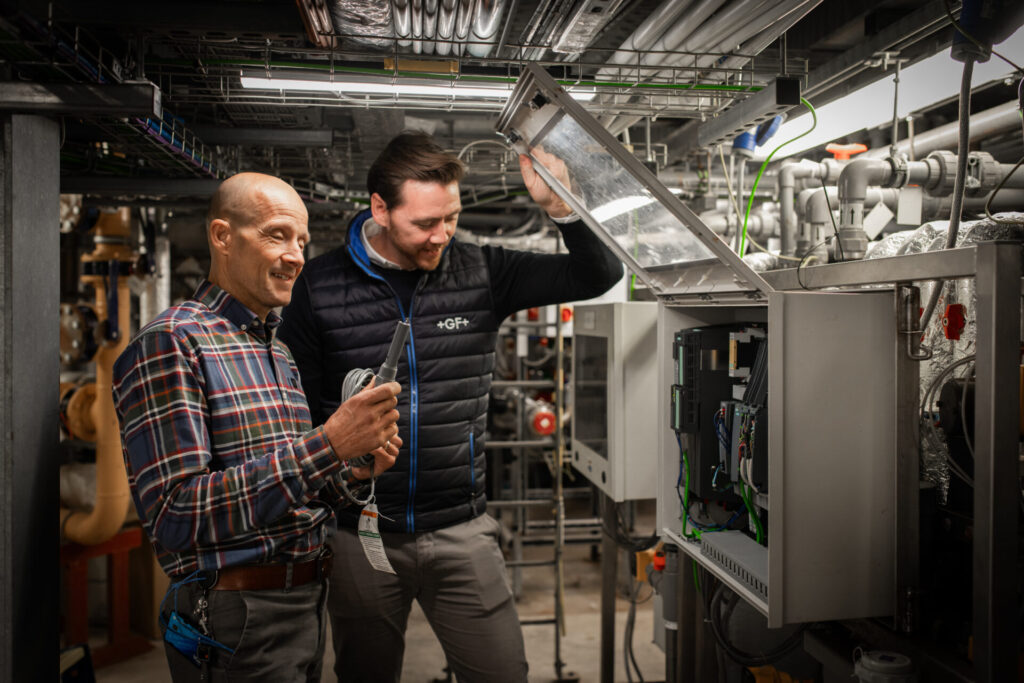

With an extensive background in process instrumentation, GF has been the company’s long-time supplier for liquid analysis solutions as well as valves and actuation capable of performing under challenging conditions. Scymaris relies on GF’s components to measure dissolved oxygen, temperature, and pressure. In addition, the company has implemented conductivity sensors made of Hastelloy C-276 which have an expected service life four times longer than 316L stainless steel thanks to higher corrosion resistance. As part of a scheduled equipment update, Scymaris chose to install the 9950 Six-Channel Transmitter which can accommodate up to 6 different instruments with 100% customizable in- and outputs.

When it comes to technology used for scientific studies, reliability and accuracy are of the highest importance. Components like GF’s conductivity sensors not only feature durable materials but also undergo rigorous testing before leaving the factory. At the same time, the 9950 Six-Channel Transmitter reduces the potential points of failure and simplifies the process of monitoring critical parameters. The durable, reliable, and precise system helps studies to run smoothly and fulfill the stringent guidelines of clients and the government.

Paul Kersey, Facilities and Engineering Team Leader at Scymaris, comments on the importance of GF Piping Systems’ solutions for the company’s case studies: “Ultimately, every study we do in this facility is there to protect the environment for the future. Accuracy is incredibly important as our clients have very stringent guidelines, so working with GF is really beneficial for us – it gives us some great resilience across all of our engineering assets.”

The facility in Brixham was already being used for environmental risk assessments before Scymaris started operations there, and GF has been its automation partner for the past 20 years. As a result, ensuring a good, stable water supply with components that are easy to operate and maintain has always been a priority. In 2008, GF supplied a complete solution consisting of actuated valves as well as sensors for parameters including flow, level, temperature, pressure, pH, and salinity.

Sanjay Patel, Head of Global Customer Success at GF, was heavily involved in the 2008 project. “The Brixham Environmental Laboratory project exemplifies a scenario where the customer not only required high-performance plastic piping systems, including automation and fittings, but also benefitted from the fact that all necessary instrumentation could be sourced through GF. The customer was particularly impressed by the cost-effectiveness of our instrumentation due to our use of engineered plastics over traditional metal components.” The facility’s continued focus on environmental risk assessments means that Scymaris relies on many of the same systems that were installed nearly 20 years ago – including GF’s components, as Sanjay emphasizes. “It has been amazing to see the durability of the plastic components first hand,” Patel adds. “Applications involving seawater are always extremely challenging, so we are proud that our products are still going strong after all these years.”

Customer benefits:

Durability: Thanks to a wide range of proven materials, liquid analysis components by GF Piping Systems are designed for a long-lasting operation – even in challenging conditions.

Precision: Transmitters by GF Piping Systems allow operators to easily monitor and control critical parameters.

Customization: Comprehensive measurement solutions ensure full compatibility and seamless integration.