The sheer breadth of electrical tomography’s range and versatility should have become abundantly clear to regular FluidHandlingPro readers in recent weeks, however it is in the field of food and beverage production that electrical tomography could have its greatest potential yet.

Electrical tomography’s four main process monitoring functionalities – mixing, separation, level detection, and flow – all neatly reside within the ambit of FMCG, food, and beverage production. Whether these functionalities are deployed individually or in concert, the fluidised nature of many FMCG, food, and beverage constituents, or final product, means that electrical tomography can be applied to virtually any part of the production process to ensure product quality and process efficiency.

Since there is a substantial overlap between electrical tomography’s use in the dairy industry and food and beverage applications, it isn’t necessary to repeat the same points all over again which can be read here. Instead, it is instructive to review some recent developments regarding the use of electrical resistance tomography (ERT) in the food and beverage sector to monitor hygiene.

Hygiene is obviously a paramount concern for any food and beverage manufacturer. Maintaining high standards is obviously essential in the interests of regulatory compliance, product quality, and process efficiency. To this end, ERT has shown excellent results by being able to monitor and detect contaminating surface deposits found in food production lines, sundry pipework, and plant.

Three published academic papers have examined the issue of hygiene monitoring and contamination prevention using ERT. These yielded some very promising results, especially for large operations where “Cleaning-In-Place” (CIP) protocols are required because it is unfeasible and impractical to dismantle an entire production line for cleaning.

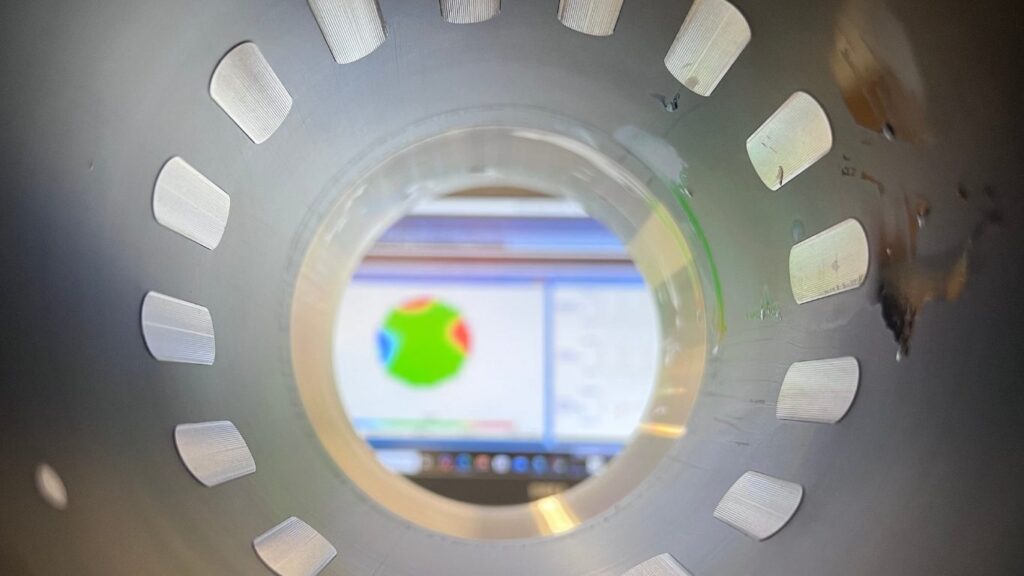

In a joint collaboration between the University of Manchester, Cranfield University, and Unilvever; a linear ERT sensor was developed to detect “fouling” – the result of deposits adhering to equipment surfaces and pipework. While other detection methods focus on a hygiene endpoint and monitor what has been removed, ERT had the advantage of being able to detect any remaining contaminants – surely a more important objective.

Overall, the paper showed that ERT was “suitable for monitoring the pre-rinse stage for CIP for materials which foul similarly to milk pastes. As this process can be conducted in real time, it is a convenient technique and can save time and money as the cleaning process can be visualised and over cleaning can be avoided.” The paper can be accessed here.

In a slightly older study, ERT was studied alongside computational fluid dynamics (CFD) to assess the rheological properties of yoghurt and water as a way to better understand their respective laminar flow and turbulent mixing properties to help achieve, amongst other information, a better cleaning outcome.

Understanding the differences in displacement behaviour of these two contrasting liquids has many advantages. As the paper states, “ The details of the displacement behaviour are of particular concern to the food industry where the cost of raw materials is orders of magnitude higher than processing cost.” The paper can be found here.

Published only this year, a new hygiene-focused study from the University of Auckland in New Zealand has made further progress by recognising ERT’s potential for identifying production plant fouling within a dairy food manufacturing context by being able to distinguish different states of fouling through their individual and contrasting conductivity profile.

The New Zealand research found “a clear correlation between fouling thickness and changes in conductivity, with tomographic images effectively distinguishing between different fouling levels.”

These findings are extremely promising and become even more compelling when ERT’s technological and operational advantages, compared with other technologies, are also factored in. As we all know, ERT’s chief advantages are its real-time monitoring capabilities combined with its non-invasive operational data acquisition protocol. ERT’s non-invasive capabilities are obviously in harmony with the food and beverage industry’s mandatory quest for hygiene.

The paper’s conclusions could serve equally well as a summary for all the papers mentioned previously through the following: “By providing real-time insights into fouling accumulation, ERT can enhance process monitoring, reduce downtime, and improve the operational efficiency in the dairy industry.” The paper is linked here.

There is no doubt that hygiene monitoring represents a significant addition to ERT’s seemingly endless list of applications and addresses a vital operational concern for the entire food and beverage industry. While this new functionality is in its early stages, and there is still work to do, it will be easy to upscale to a pilot plant or industry rollout.

To find out more about ITS’s broad range of electrical tomography solutions and applications, please contact sales.support@its.com or visit the ITS website.