When blending liquids of similar viscosity together, conventional mixing equipment and agitators are suitable for the job. But, if the mixing process is any more complex than this, swapping the stirrer or agitator for a high shear mixer could help manufacturers to achieve shorter mixing times, lower processing costs and a better product.

For example, where there is a significant difference in viscosity between two liquids being processed, an agitator tends to move the two liquids around without actually blending them together. It can take a long time to achieve a uniform blend. For example, when manufacturing honey-based products, which can be extremely difficult to process due to the viscosity and ‘sticky’ characteristics and stratification could occur in the mix.

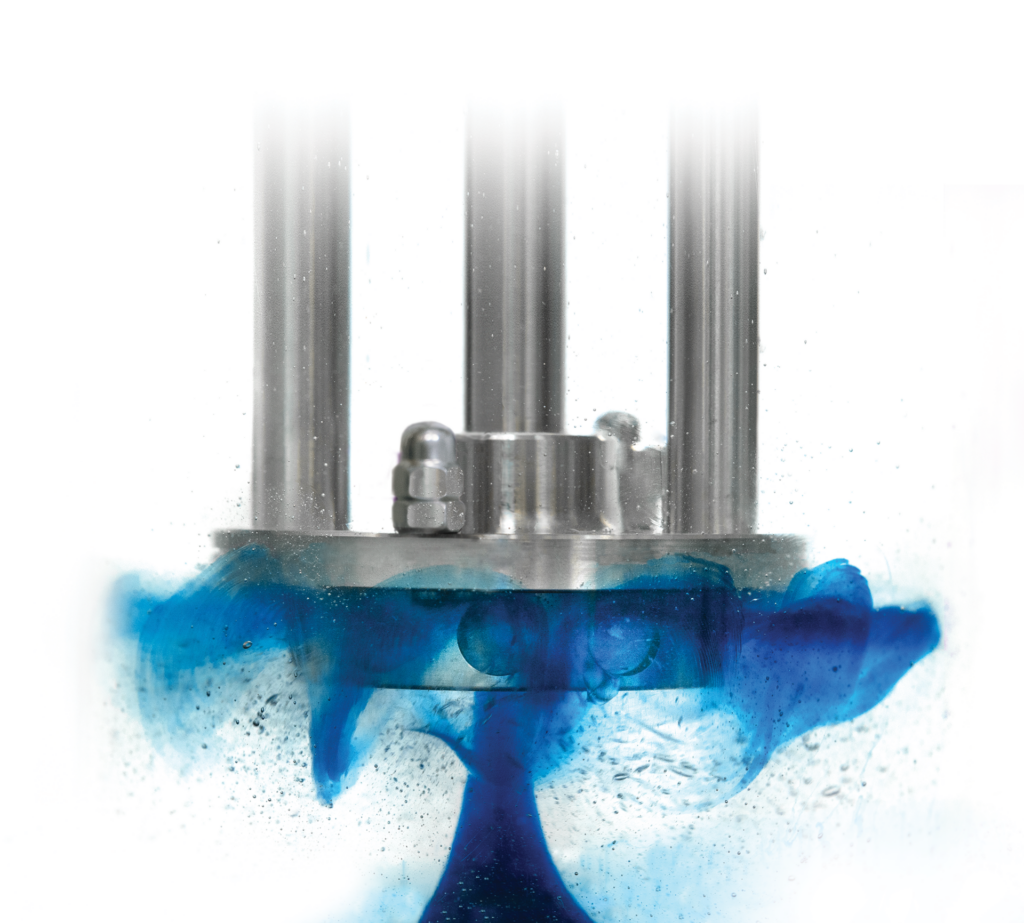

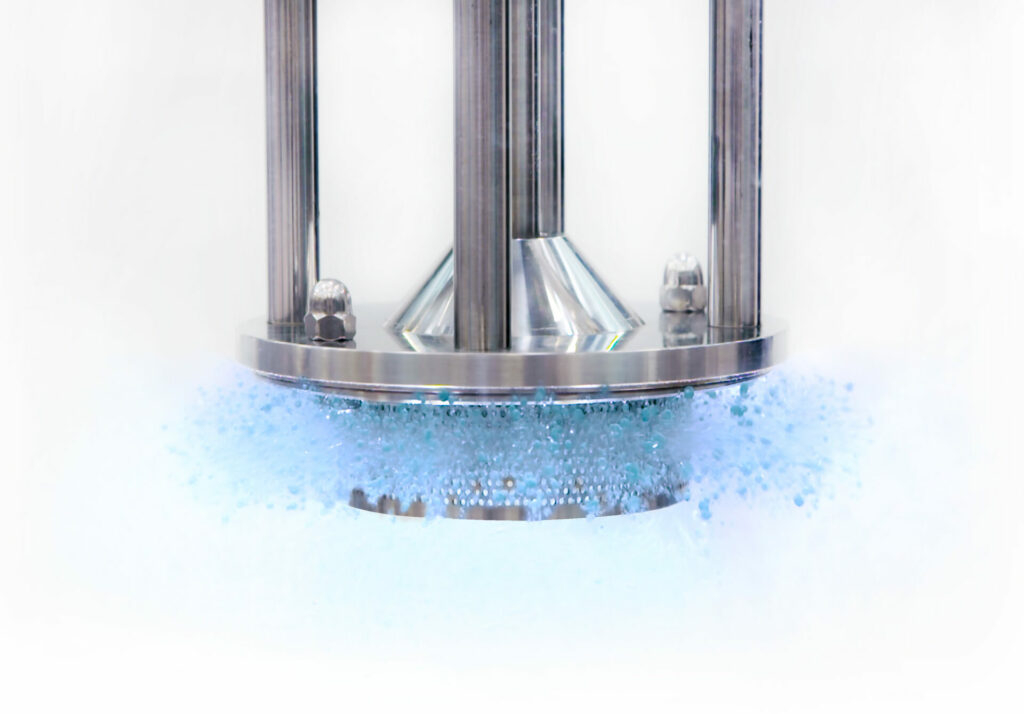

With high shear mixers, the positive mixing action of the rotor/stator assembly draws the liquids into the workhead where they are rapidly combined before being forced out through the stator and projected back into the vessel. The liquids are blended almost instantaneously, rapidly reducing the mixing times.

Another example of where a high shear mixer can be beneficial in place of traditional mixing methods is when creating emulsions.

Creating a stable emulsion can be a challenging task, even with the use of emulsifiers, but it is a critical stage in the production of many products. The consistency, quality, texture, shelf life and appearance of products are very much dependant on the stability of the emulsion. The challenges of the process can be increased by the use of unsuitable mixing equipment.

In order to form a stable emulsion, whether you are producing an oil-in-water or water-in-oil emulsion, you need to obtain the finest possible droplet size. The mixing equipment needs to impart a large amount of energy into the mix, the more shear energy introduced into the mix, the smaller the suspended droplets will become, creating a fine stable emulsion with both phases completely and uniformly dispersed into one another.

Conventional mixers and agitators are unable to form a stable emulsion because they do not have the necessary means to impart large amounts of energy into the mix. This type of mixing equipment simply moves the two liquid phases around the vessel, so although it may appear as though the phases have blended, the droplet size hasn’t been significantly reduced, so once the agitation stops the emulsion will soon separate into the two distinct phases once more.

High shear mixing subjects the liquids to intense high-energy which reduces the droplet size sufficiently and allows the two phases to combine, resulting in a stable emulsion which will not separate once the shear energy has been removed. This can increase product quality and again reducing mixing times and costs.

Homogenisation is another area where manufacturers may benefit from switching from the traditional mixing equipment associated with this application – high pressure homogenisers – to a high shear mixer.

High pressure homogenisers are powerful devices that use a piston pump to force product through a very small adjustable aperture at high pressure. Although these devices can ensure homogeneous products, they require a large amount of energy and capital expenditure. However, what many people don’t realise is that for the vast majority of products a high pressure homogeniser isn’t actually required. Reducing the globule or particle size down to around 2 – 5 microns is a sufficient degree of homogenisation for products such as creams and ointments, suspensions, etc. A high shear mixer/homogeniser can achieve a globule or droplet size in this range of and in some cases, depending on the formulation, finer results down to 0.5 microns can also be obtained. This eliminates the need for expensive homogenisation equipment in the manufacturing process and can reduce running costs.

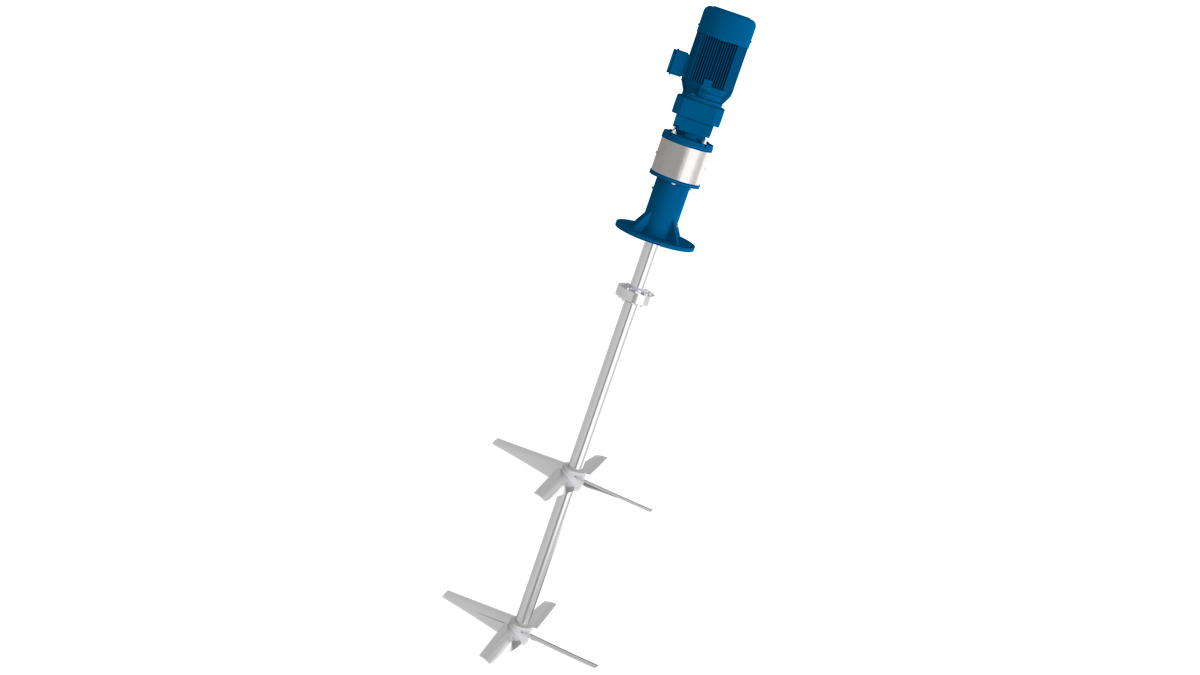

Silverson High Shear Mixers are able to achieve results unreachable to traditional stirrers and agitators due the precision engineered rotor/stator workhead. This workhead generates exceptionally high shear rates in a three stage mixing/homogenising process. Firstly the high speed rotor draws materials into the workhead where they are intensely mixed. Centrifugal force then drives the materials to the periphery of the workhead and subjects them to mechanical shear in the precision gap between the rotor and stator. This is followed by intense hydraulic shear, as the product is forced through the stator screen at high velocity and circulated back into the mix. Fresh material is continually drawn into the workhead, progressively reducing particle size and quickly resulting in a homogeneous, uniform product. Ideal for blending liquids of varying viscosities, forming stable emulsions and reducing particle sizes.

If you’d like to find out more about how Silverson can help you, please visit www.silverson.co.uk or contact sales@silverson.co.uk.