Silverson Machines are proud to be known as the world leader in the specialised design and manufacture of large-scale rotor/stator mixers, with capacities of up to 30,000 litres. All our large-scale machines are individually built to order and constructed specifically to suit each customer’s requirements.

In-Tank Batch Mixers

These large-scale in-tank mixers possess all the qualities and flexibility of Silverson’s medium range models and work on the same mixing principle, but they include a number of additional and unique features.

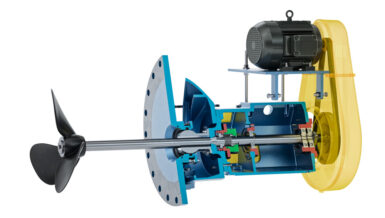

Each mixer in the Silverson product range is designed and built to the highest possible engineering standards. For large-scale in-tank mixers these designs include specially balanced motors and the fitting of precision ground shafts which are finish turned in-house. This helps to ensure critical vibration free running which is essential at larger-scales. Quick release shaft couplings, split two-part downthrust propellers and hard-surfaced sacrificial shaft journal sleeves are just a few of the features designed to keep maintenance and downtime to a minimum.

One of Silverson Machines’ unique selling points is the ability to scale up our mixing equipment from the laboratory to full scale production models. Many mixer manufacturers offer high speed laboratory mixers that have no production equivalent. Silverson, on the other hand, offers the largest range of capacities from a single manufacturer – from 1 ml laboratory units up to some of the largest disintegrator systems on the market – with all Silverson mixers manufactured to the same precision engineered tolerances. As a result, we can offer scalable results across our entire product range. As such, these large-scale in-tank Batch mixers work in the same way as other in-tank rotor/stator mixers in the range. As with Silverson medium-scale Batch mixers, these larger equivalents can perform a range of mixing processes including but not limited to emulsifying, homogenising, solubilising and blending.

Here’s how it works: The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the centre of the workhead. Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator. This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix. The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimises aeration caused by the disturbance of the liquid’s surface.

Silverson Machines also offers a range of other large-scale mixers, such as the Silverson Duplex Disintegrator and the D2500 Disintegrator/Dissolver for solid/liquid mixing processes.

For more information, or to discuss your application, please visit the Silverson website.