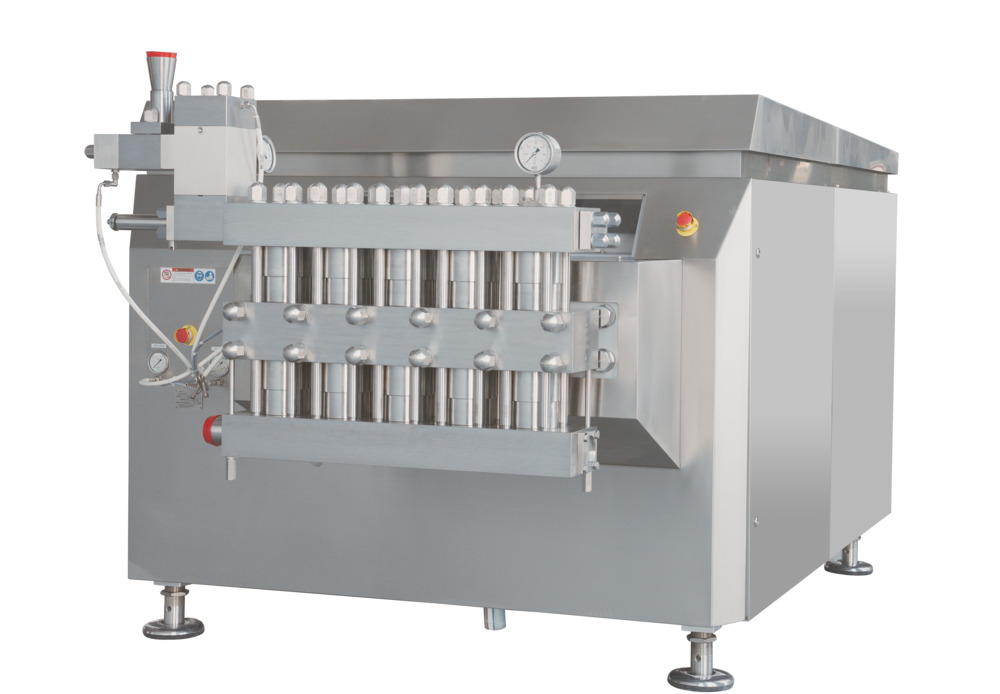

Charlotte, N.C.– APV®, a brand of SPX FLOW, has released new versions of its Rannie and Gaulin homogenizer lines to provide food and beverage, dairy, chemical and industrial processors more power in a smaller footprint. The 160T and 160Q models offer the same capacity as larger homogenizers without increasing equipment size.

To learn more about the 160T and 160Q Rannie and Gaulin homogenizers, visit Homogenizers

With the expansion of the Rannie and Gaulin lines, customers have more options to ensure they get the right size and capacity to fit their needs, with the proven performance and quality of APV homogenizers.

Features of the new 160T and 160Q models include:

- Greater versatility and flexibility in duties: The new models are designed for a wide range of applications and capacities, including 20,000 liters per hour (5,290 gallons per hour) at a pressure of 250 bar, which is typically seen in larger homogenizers.

- Long service life with minimal maintenance: Available with either three or five plunger configurations, each model features a durable, slow-speed power end that minimizes vibration and noise. They also offer easy access to the hydraulic actuation system, lubrication oil and other auxiliary systems, simplifying maintenance while reducing downtime and costs.

- Wide array of configurations: The updated models include options such as pharmaceutical-grade specifications and explosion-proof designs, providing a larger range of uses and more specialized applications.

- Extensive aftermarket support: The APV Rannie and Gaulin lines offer proven quality backed by a global service and support network.

SPX FLOW Global Product Manager of Dispersion Products, Con O’Driscoll: “Our customers asked, and we listened: they needed more power without adding to the size of their homogenizers. With the addition of the 160T and 160Q models, our customers now have the value and capacity they need, in a size that best fits their space. We’re excited to expand our offerings, giving our customers more flexibility and options to reach and exceed their goals.”