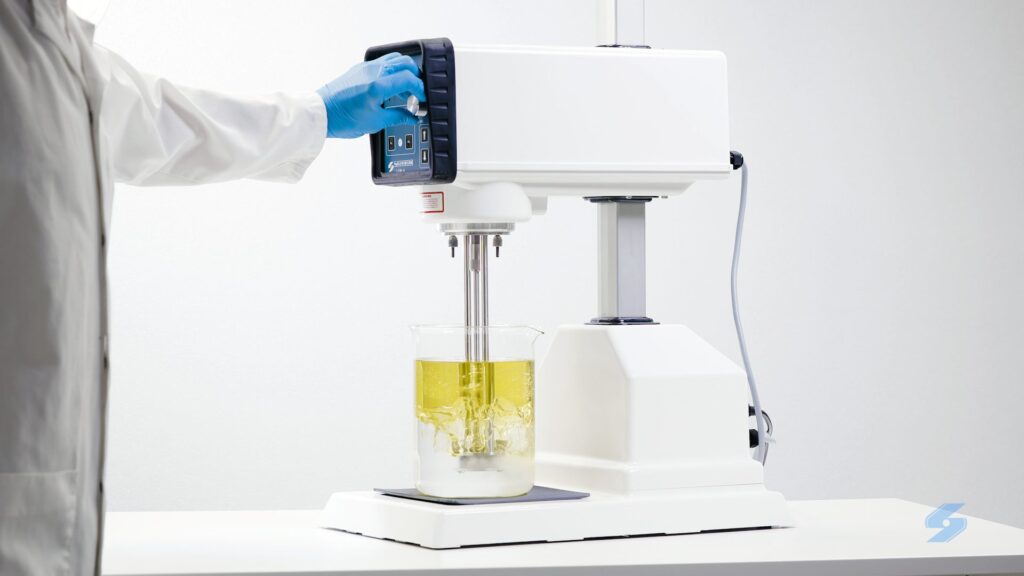

For example, the same mixer being used to produce stable emulsions for cosmetic creams and lotions, could also be used for blending liquids of widely differing viscosities in shampoo manufacture, and mixing high viscosity products such as gels.

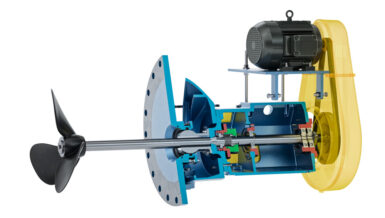

How can one mixer achieve high quality batch-to-batch results in such varied applications? The answer lies at the heart of every Silverson mixer – the rotor/stator workhead. ‘Shear’ in the simplest terms, means to cut. Silverson high shear mixers achieve the ‘cutting’ action as the blades of the rotor rotate inside a static stator.

The high-speed rotation of these rotor blades a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the centre of the workhead. Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator. This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix. The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle.

The versatility of Silverson high shear mixers is further increased by the range of interchangeable workheads. With a range of options, the perforations in the stators can be changed to suit specific applications and processes. For example, the emulsor screen is ideal for liquid/liquid preparations and especially useful for applications which require the forming of stable emulsions. Whereas the General Purpose Disintegrator Head is ideal for general mixing applications. This workhead is the most versatile of all the heads, giving an exceptionally vigorous mixing action.

Time after time, companies specify Silverson mixers as the “standard” equipment for their manufacturing process, with a single Silverson high shear mixer able to perform a wide range of mixing applications with speed and consistency. With the exceptionally rapid mixing action of a Silverson high shear mixer, process times are substantially reduced compared to a conventional agitator.

Silverson mixers are advantageous when:

- Homogenising: In many cases, a Silverson mixer can replace a high-pressure homogeniser in a processing line. They can also be used to create a uniform premix that will pass through a high-pressure homogeniser at a much faster rate and often in a single pass.

- High Viscosity mixing: The innovative pumping rotor design of some Silverson mixers allows them to process higher viscosity products.

- Blending liquids of varying viscosities

- Forming stable emulsions: A Silverson mixer can easily create a stable emulsion with a droplet size of 2 – 5 microns, results down to 0.5 microns can be achieved depending on the formulation.

- As well as many other liquid/liquid and powder/liquid mixing applications.

For companies manufacturing multiple products in their factory, many of the Silverson in-tank models are available on mobile floor stands. This option greatly increases the flexibility of these mixers, allowing them to be moved from vessel to vessel and to be raised and lowered during operation, if required, to give the optimum mixing position at varying stages of the process.

For mixing In-Line, all Silverson In-Line mixers are designed for cleaning in place (CIP). This enables thorough cleaning of the equipment between batches without the need for dismantling, saving time and allowing subsequent batches to be processed quickly and easily.

Silverson Machines offer the largest capacity range from a single manufacturer and part of our success – and that of our clients – is the accuracy with which we can predict the performance of our production scale mixers based on laboratory trials.

We see no point in using a laboratory mixer capable of speeds of 25,000 rpm or more if the results cannot be replicated in production. That’s why all Silverson laboratory mixers are designed and built to the same tolerances as the production units; comparable rotor tip speed and shear rates across the entire product line means scalable results, every time.

Join thousands of satisfied customers who trust Silverson Machines with their mixing needs. Get in touch today to discuss your application or arrange a trial and see the benefits for yourself.