Background / Requirement

- Incorporation of Carbopol and 40% Carbamide Peroxide into Glycerine

- Carbopol is difficult to disperse into Glycerine because the low pH Glycerine solution results in instant hydration and viscosity increase

- 40% by weight Carbamide Peroxide is added to the Carbopol solution in a recirculation to the mixing vessel

- Need to increase production without expanding the facility.

Quadro’s Approach to manufacturing toothpaste

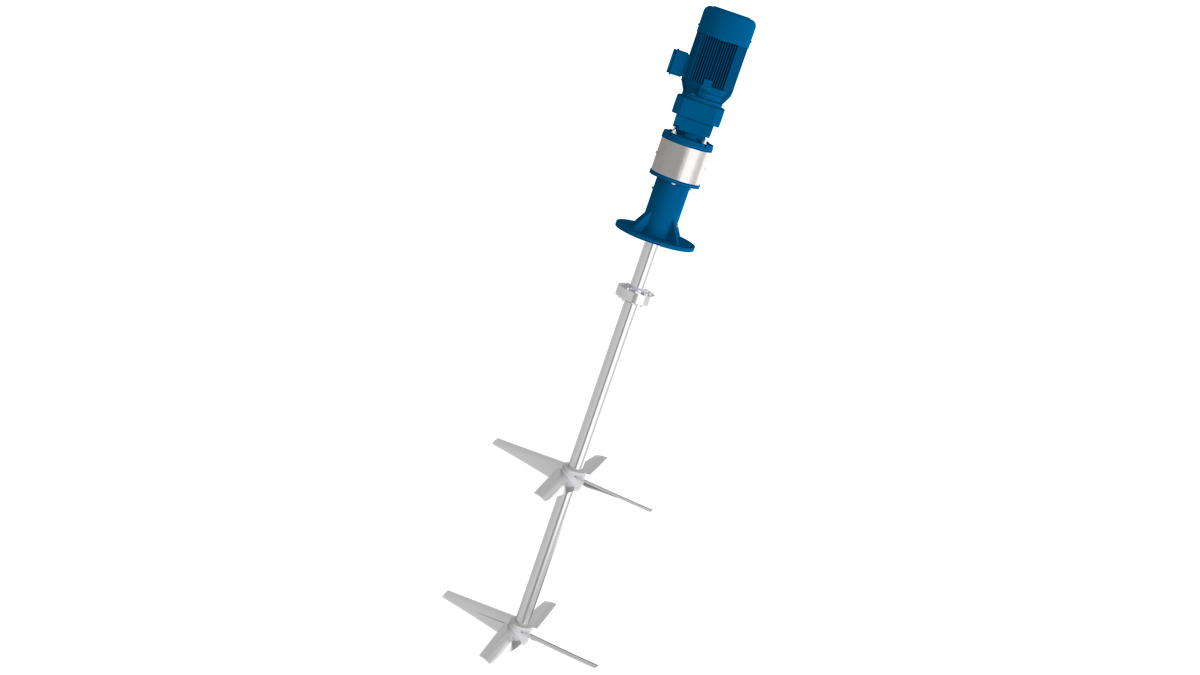

ZC1 inline disperser, skid mounted with a dual PD pump arrangement for performance with high viscosities and high solids addition rates and automated Q-Vac vacuum powder addition system

- Controls to allow (3) pre-set operating points on inlet and discharge pumps

- Carbopol addition

- Carbamide Peroxide addition

- Auxiliary setting

Automated powder valve with level sensors in the hopper to control powder on/off addition.

Quadro YTron® ZC Powder Disperser Advantages

- 75% reduction in overall batch time vs. conventional in-tank mixer processing

- Rapid incorporation & dispersion of solids without lumps or ‘fish-eyes’

- Improved product consistency from batch to batch

- Increase in viscosity, the customer was able to reformulate and use less polymer

- Eliminated requirement to filter undispersed powders

- No over-processing is common with conventional mixers preserving the rheological properties of shear-sensitive products

- Significantly reduced air entrainment

- Elimination of quality problems associated with cross batch contamination

- No excessive dusting from bag dumping into process vessels

- No solids build-up on process vessel walls

- Elimination of the requirement to expand the manufacturing area to increase production.

To learn more about our High Shear Mixing Equipment or to speak to a member of our applications team please contact us to speak to our team of applications experts