Results

- Integrated Pressure Relief Valve (PRV) solution with wired switches to enable firewater system activation

- Customized PRV monitoring solution tailored to meet stringent project and licensor requirements

Application

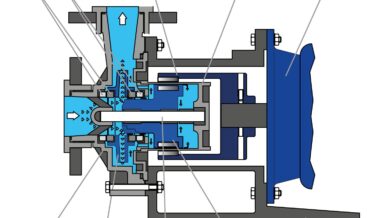

Pressure Relief Valve (PRV) Monitoring with Firewater Activation Integration

Customer

A leading global engineering, procurement, and construction (EPC) company headquartered in Japan

Challenge

The process licensor mandated the integration of wired limit switches with PRVs for firewater activation, while the EPC project team sought a digital PRV monitoring solution with robust technical support.

Operating conditions included elevated process temperatures up to 270 °C, presenting additional engineering complexity.

Most available market solutions were limited to direct spring-operated PRVs designed only for ambient temperatures, making them unsuitable for this application.

Solution

Emerson collaborated closely with the EPC and project stakeholders, offering specialist engineering guidance and leveraging a proven track record in PRV monitoring across critical applications.

To meet the challenge, Emerson proposed a customized PRV digital monitoring solution that integrates seamlessly with wired limit switches, ensuring alignment with the process licensor’s firewater system activation requirements. The solution was specifically engineered to endure high-temperature conditions of up to 270°C—far beyond the limits of most conventional ambient-rated devices.

Key components included:

- High-temperature rated limit switches designed to deliver reliable performance in elevated process environments.

- Digital monitoring interface enabling real-time visibility and diagnostics of PRV status for enhanced safety and maintenance planning.

- Robust mounting and enclosure design to ensure long-term durability in harsh conditions.

- Compliance documentation and close collaboration with the EPC to satisfy all licensor specifications and reduce project risk.

This integrated approach not only met the licensor’s safety criteria but also provided the EPC with a scalable and reliable digital monitoring solution, backed by Emerson’s regional engineering support and global application expertise.