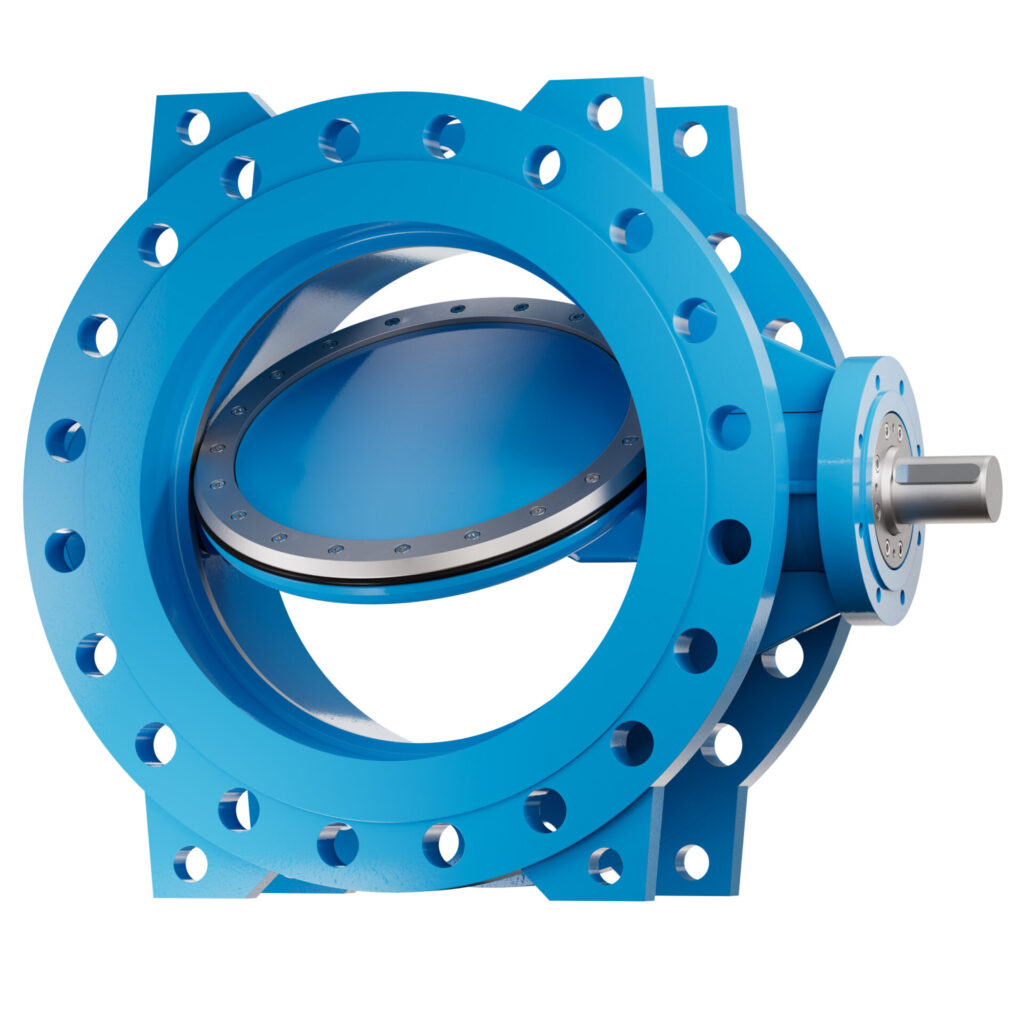

Hagen, May 2025: With the newly added WS112 butterfly valve, EBRO now offers the water industry a double-eccentric designed valve for water applications. The valve is suitable for water distribution, water transport, and water treatment. The seal-on-disc design of this double-flanged valve ensures reliable bi-directional tightness.

WS112: For Demanding Applications Such as Wastewater Systems or Seawater Desalination Plants

The WS112 is engineered to meet even the most demanding operating conditions. Thanks to its double-eccentric design with a polygonal shaft connection, friction is reduced and wear is minimized. This construction principle also results in low actuation torque—making the EBRO WS112 the ideal choice for high-flow water pipelines, such as those used in wastewater systems or seawater desalination plants.

Key Design Feature #1: Polygonal Design and Dry-Shaft Construction

The polygonal design of the shaft ensures optimal torque transmission to the disc without the need for bolts or pins. This positive-fit connection is ideal for valves operated infrequently, such as once or twice a year. The dry-shaft design with self-lubricating precision bearings, O-rings, and enclosed disc hubs guarantees long-term corrosion protection and minimal maintenance.

Key Design Feature #2: Double-Eccentric Butterfly Valve with Replaceable T-Seal

The double-offset geometry ensures that the disc lifts cleanly away from the seat ring during operation, reducing wear and torque. In case of maintenance, the precision-molded T-seal can be easily replaced. It is held in place by a one-piece retaining ring, which is simply unscrewed for quick and straightforward maintenance. The body is protected by a high-quality corrosion-resistant epoxy coating—either fusion-bonded epoxy (FBE) or two-pack liquid epoxy, depending on valve size.

Nominal Sizes and Pressure Ratings: Key Data of the EBRO WS112

The EBRO WS112 is available exclusively in a double-flanged design, covering nominal sizes from DN 100 to DN 1600. Larger sizes up to DN 2200 are available upon request. The valve supports pressure ratings PN 10, 16, 25, and 40 and is compliant with face-to-face dimensions according to EN 558-1 Series 14 and Series 13, as well as DIN 3202 F4 and F16.

The standard valve body is made of ductile iron. Other materials such as carbon steel, stainless steel, and nickel-aluminium-bronze are available on request. In addition to electric actuators, other options such as manual gearboxes or pneumatic actuators are available for the WS112.