Habonim valves support all stages of the hydrogen production process:

- Production

- Conditioning

- Delivery / Supply

- Refueling / Mobility

- Onsite Electrolysis

- Industrial Use

From hydrogen production methods including steam methane reforming and electrolysis – where Industrial Hydrogen valve models, notably Habonim H47, H73, and H31, deliver robust performance – to conditioning processes involving compression, in which Habonim’s Ultra-High-Pressure Hydrogen Process Valve models, namely H25, H29, and H99 (rated at 550 bar / 8,000 psi and1,034 bar / 15,000 psi respectively) are one of their kind by design and performance.

All Habonim valves are supplied for manual operation or as an automated valve package.

Habonim valves are equipped with the Total HermetiX Integrity Package, which includes the Hydrogen-use HermetiX stem sealing (registered EU design 015025978-0001) with double body sealing, zero fugitive- emission no maintenance stem sealing, and fire-safe with superior In-line sealing.

Hydrogen Process Valves – For Service Across the Hydrogen Supply Chain

Closely working with the leaders of the hydrogen supply chain over the last years has resulted in establishing the widest range of valve solutions to support all its stages. As part of this process, Habonim has identified a market gap and developed a comprehensive category of Ultra-High-Pressure Hydrogen-Use Process Valves for pressure ratings ranging from 550 bar (8,000 psi) to 1,034 bar (15,000 psi), along with a full range of required safety and standards certifications.

In the delivery and supply phase, which includes compressed gaseous hydrogen (CGH2), TPED-certified valves, such as Habonim models H24, H25, and H29, offer threaded and cone & thread end connections with pressure ratings of up to 700 bar (10,000 psi) – making them ideal for all hydrogen transport applications.

For hydrogen transport applications, such as trucks, trailers, ISO tanks, and refueling terminals, Habonim has developed the H21 Valve model – a high-pressure, high-flow solution for welded lines, available in sizes ranging from ½” to 2” and rated up to 600 bar (8,750 psi).

At the end of the hydrogen fuel supply chain – refueling stations where tight sealing and fast response are essential – Habonim’s ISO 19880-3 certified valve models H25 and H99 deliver unmatched performance. These three-piece designs support H35 and H70 systems, respectively, with a full array of safety certifications, including ATEX for explosive environments, SIL for hazardous process loops, fire-safe, and more.

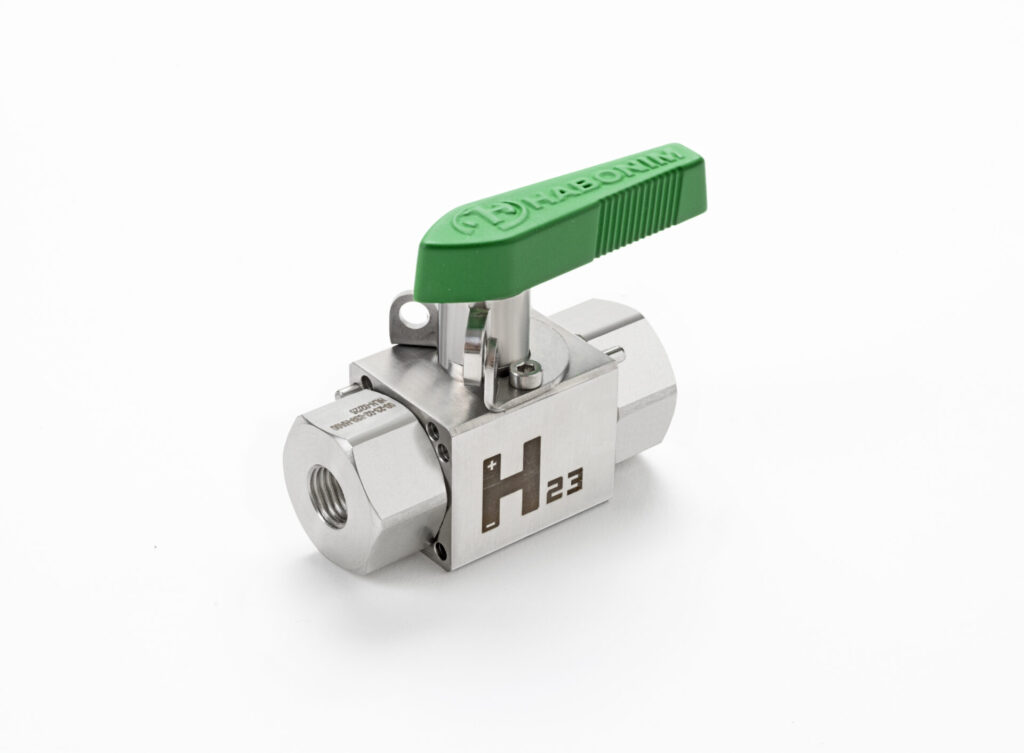

Hydrogen Service Valve: The Habonim H23 Valve model – A New Benchmark in Hydrogen Service Valve Technology

In addition to the Hydrogen-Use Process Valve models, Habonim has introduced a Service Valve for hydrogen use: the H23 Valve model – a three-piece floating ball valve designed exclusively for hydrogen service. It features the Total HermetiX Integrity Package, which includes HermetiX stem sealing, double body sealing, fully fire-safe construction, and superior inline sealing.

The H23 stands out with its anti-blowout stem design, embedded high-pressure AED O-ring, integral locking device, and flexible mounting options (panel or bottom), making it a secure and versatile choice for general shut-off applications across the hydrogen supply chain.

What truly sets the H23 apart is its hydrogen-specific design, development, and testing – backed by a comprehensive set of certifications, including:

- ASME BPVC VIII Div I UG-101

- ATEX IIC

- SIL2/3

- ISO 15848-1 (Fugitive Emissions)

- API 641

- ISO 10497

- API 607 (Fire-Safe)

Available in both manual and automated configurations, the H23 can be paired with Habonim’s CompAct C15 pneumatic actuator– ideal for installations in tight spaces.

Valves for Hydrogen-As-A-Fuel: Building the Future Now

Habonim was the first ball valve manufacturer to certify its products to hydrogen-specific standards, such as ISO 19880-3 and ISO 23826. As a pioneer in hydrogen valve technology, Habonim continues to lead the industry with specialized solutions that meet the most demanding applications-ensuring safety, reliability, and efficiency across the entire hydrogen ecosystem.