“At the start we always have to do some convincing”, says Selcuk Aslan, Energify Project Manager at CFT. “Our system is highly developed, but the idea and the basic design are actually very simple. For that reason people are sometimes sceptical. However, once they have seen and understood Energify, they are quickly convinced by the robustness and reliability of the technology – and that ‘simple’ is therefore also a great advantage.”

With Energify, CFT offers a solution to challenges that almost all industrial companies are facing: the reduction of CO₂ emissions and the improvement of energy- and cost-efficiency. The innovative system utilises even slight pressure differences to generate power and feed it into the factory’s own grid. Such pressure differences exist in almost all industrial plants. They occur in pressure reduction stations and exhaust steam pipes as well as in condensation and back pressure systems – and in most cases the energy stored in the fluids goes to waste.

Optimal utilisation of the already used energy

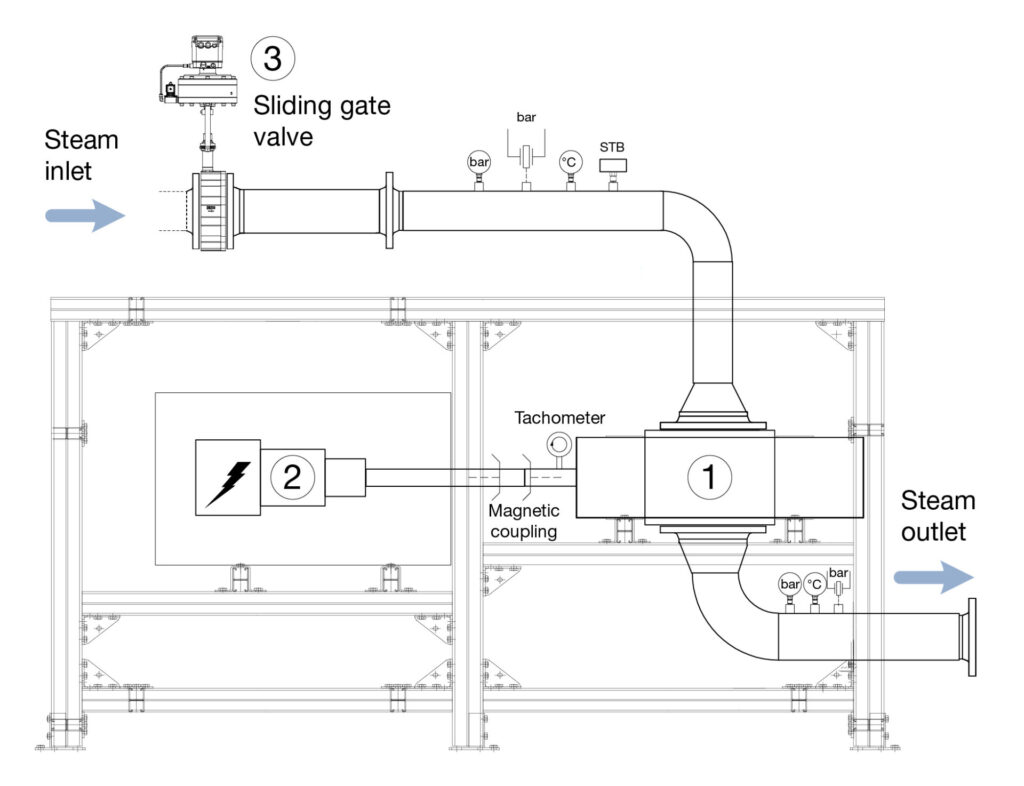

“Energify optimises the use of the already existing energy”, explains Maximilian Igelbüscher, project engineer at CFT. “In order to guarantee an uninterrupted process, our system is always operated in the bypass. The basic design is as follows: Steam, or a gas of any kind, is expanded to a low pressure level in a rotary piston expander. This generates mechanical energy. This energy is transmitted via a shaft to an asynchronous generator, which then inputs the electricity into the low voltage grid.”

Initially, it was difficult to precisely control the expander performance. The globe control valve originally used reacted too slowly to changing process requirements and could not reliably provide the gaseous medium with the desired output pressure. “We spent a lot of time looking for a solution to optimise our system in this respect. Ultimately, we made contact with Marcel Mokosch from Technical Sales at Schubert & Salzer. He visited us immediately to discuss the topic and proposed a solution with the sliding gate valve, which not only met our expectations, but even exceeded them”, says Igelbüscher.

Significant improvement through the use of the sliding gate valve

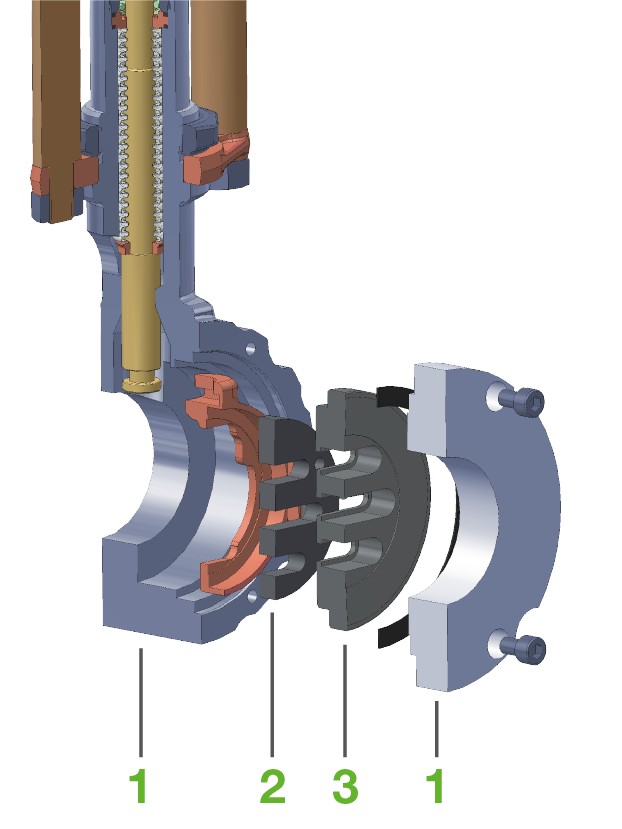

The reason for the excellent control performance is the fundamental design principle of Schubert & Salzer’s sliding gate valve, which is based on two sealing discs that slide over each other (see info box). As a result, the maximum stroke between open and closed is a mere 6-9 mm and only very low actuation forces are required. This makes control extremely precise and agile. “The control accuracy has improved considerably through the use of the sliding gate valve. We can now control the output pressure with absolute precision”, says Aslan.

A further advantage: The use of the sliding gate valve allowed two other valves to be replaced. For reasons of safety, it must be possible to stop the supply of steam or gas within a maximum of two seconds. For that reason a quick-closing valve was previously installed upstream of the control valve. However, sliding gate valves close within milliseconds and also perform this function. “Reliability and low maintenance costs play a decisive role in the cost-effective operation of a system like Energify. That’s why we rely on a simple design and a robust construction”, explains Aslan. “The sliding gate valve helps us by reducing the complexity of the system – and with a very compact design, too.”

The difference to the previous technology is clear: the DN80 Schubert & Salzer sliding gate valve now used weighs a mere 15 kg, whereas the two globe valves previously used weighed together around 170 kg. “That’s an enormous advantage, especially for the annually necessary maintenance work”, Igelbüscher adds.

More economical than photovoltaics

The Energify demonstration system is located in a dairy in Münsterland, where it is used on the 8-bar steam mains. The cost-effectiveness of the system can be illustrated well here: With an input pressure of 8 bar (g), an output pressure of 5 bar (g) and a steam quantity of 2 t/h on average, an electrical output of 27 kW is achieved. With an annual running time of 6,500 hours, that would produce 175 MWh of power per year. The amortisation time is less than three years under these conditions. Including maintenance costs, over 270,000 Euros could be saved over an operating period of ten years.

CFT compares Energify with photovoltaics in a further calculation example: An Energify system with an output of 300 kW that achieves 8,500 operating hours per year would accordingly generate around 2,550 MWh annually – on an area of just 40 m². In order to generate the same amount of energy with photovoltaics, with an annual utilisation time of about 1,000 hours (average in Germany), an area of around 13,500 m² would be necessary.

“The technology has enormous potential. Thousands of steam generators are in use in Germany alone. And steam – in whatever form – is only one of the media from which we can produce energy. In principle, Energify can be used with virtually every gas, for instance nitrogen, coke oven gas, natural gas or hydrogen”, Selcuk Aslan concludes.