Fractionated wort boiling with stripping column

GEA QBOIL combines a stripping column with a fractionated boiling process. This reduces the thermal stress on the wort (TBI), lowers total evaporation from the typical four percent to less than 0.5 percent, and at the same time reliably removes unwanted aroma compounds such as DMS. The result: up to 35 percent energy savings compared even to modern energy storage systems – validated by the GEA Add Better label.

From pilot trials to industrial performance

“Over the past few years, we have generated robust results with QBOIL on an industrial scale. For breweries, this means that the most energy-intensive process step can now run far more resource- efficiently – without compromising on quality, flexibility or flavor,” explains Dr. Daniel Heller, Innovation Manager at GEA.

Retrofit-ready and compact

One major advantage of GEA QBOIL is its easy retrofitting. The system requires little space and can be integrated into existing brewhouse structures with minimal installation effort. This opens up a wide field of application – from medium-sized breweries to large-scale industrial operations.

“Customer feedback from the trials is clear: breweries appreciate that QBOIL can be retrofitted with minimal effort. In times of high energy costs, this is an investment that pays back quickly,” says Peter Sterk, Product Manager at GEA.

Eye-catcher with Kinetic Edge Design

GEA QBOIL also makes an impression with its appearance: the system features GEA’s new Kinetic Edge Design. The column can even be considered for visitor areas of breweries, where traditional copper kettles or modern stainless-steel domes dominate. There, it would set a visual accent signaling the transformation of brewing. “For us, QBOIL connects tradition and future. Positioned among classic copper domes, its futuristic design makes a strong statement for the next generation of brewing,” says Heller.

Trade fair highlight with tasting

With its proven energy savings and the Add Better label, QBOIL joins the range of resource-efficient GEA solutions that support breweries worldwide in achieving their climate goals. At the booth, GEA will display the column in full size. Visitors will also have the opportunity to taste the results directly with a glass of QBOIL beer. QBOIL is thus set to be one of GEA’s central highlights at drinktec.

GEA at drinktec 2025: Booth 539, Hall B5

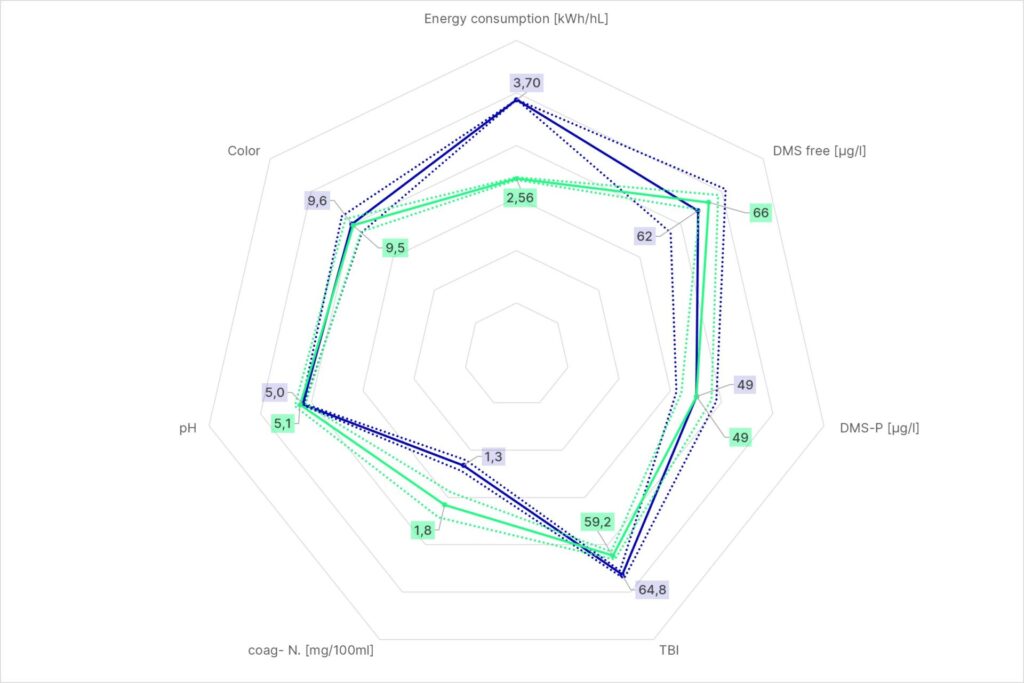

Comparison: pilot trials 2023 vs. reference plant 2025

| Parameter | Pilot trial 2023 (Brewing Academy Warsteiner Brewery) | Industrial reference plant 2025 | Result / benefit |

|---|---|---|---|

| Thermal stress (TBI) | Reduction confirmed | Reproducible on industrial scale | Less damage to the wort |

| Total evaporation | Significantly reduced | Confirmed on large scale | Energy savings with consistent wort quality |

| Energy consumption | Savings up to 30% / up to 60% compared to systems without any energy storage | Up to 35% vs. state of the art / up to 60% vs. older systems | — |

Info box:

The QBOIL principle

GEA QBOIL combines a dedicated stripping column with a heat exchanger that functions both as a vapor condenser and as a wort preheater. While lautering is still in progress, the wort is continuously fed into the kettle and brought to a boil. The energy released as vapor is used directly to preheat the incoming wort. The vapor has a dual function: it transfers heat and, in the stripping column, removes volatile unwanted compounds such as dimethyl sulfide (DMS) – all while maintaining a very low overall evaporation rate.