A key to electrical tomography’s ubiquity is its versatility by being able to provide dynamic images of what is happening inside a pipe or vessel instantaneously. This takes process monitoring well beyond conventional parametric data-based limits to include dynamic visual images to provide researchers and industry professionals with unprecedented cost-effective insights, all in real time.

Level measurement and interface detection are two applications where ERT has a proven track record in a wide range of industries and research applications where sensor options are, for all intents and purposes, bespoke. Options range from static dip probes to circular arrays around the diameter of the vessel.

As robust as they are adaptable, ITS sensors are manufactured to function in the harshest environments and have found their natural habitat in the nuclear, chemical manufacturing, oil and gas, and mineral processing industries where they have been able to withstand the most corrosive pH levels along with extremes of pressure up to 500 bar and beyond.

ITS sensors also excel in more benign environments as found in the food, beverage, FMCG, and pharmaceutical manufacturing industries. Just as they can adapt to the most severe operating conditions, ITS sensors can be made to comply with the most stringent hygiene regulations and statutory processing guidelines.

Whether you need to monitor a fluid-fluid, fluid-foam, or a fluid-solid interface, detect sedimentation, or monitor volumetric level as a discrete value; ITS data acquisition systems come in two basic options:

- P2+ is a dedicated research instrument designed for pilot plants and pure research. Flexible enough to accommodate up to 8 sensor planes, the P2+ interface is intuitive and enables the downloading of data for further offline analysis.

- The T4R is an industry-ready plug and play data acquisition option designed to be integrated into an established commercial operation. User friendly as it is fast, the T4R is equally at home in the hands of an industrial professional or researcher.

The linked video starts with a neat summary of a selection of ITS linear probes. This selection is by no means exhaustive since all linear probes are manufactured according to the client’s precise specifications.

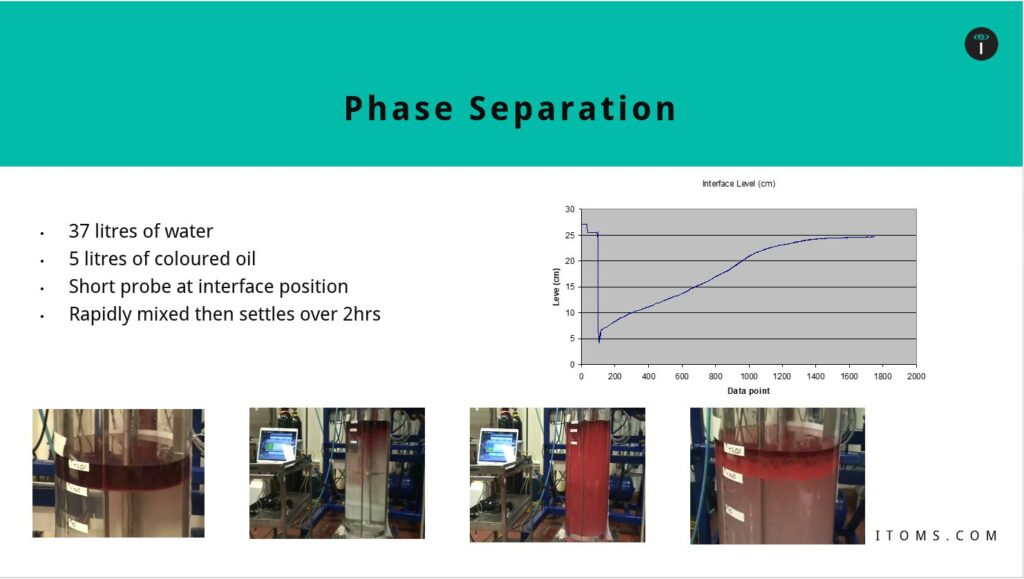

For the purposes of illustration, the video concludes with a laboratory based phase experiment mixing oil and water, accompanied with a time-lapse rendering of the user interface. The resulting tomogram or visualisation traces the path from heterogeneity to homogeneity and back again as the barrier between the oil-water constituents are observed in real-time.

The graphic below is a static representation of another oil-water mixing demonstration where homogeneity and heterogeneity are observed and depicted on a Cartesian interface instead of a tomogram.

Users of both the P2+ and T4R benefit from a modular interface design that can be adapted to the specific requirements of the end-user. This means that users have the choice of having real-time data displayed as both a back-projected software tomogram, alongside Cartesian representations of the same data.

For more information about level and interface monitoring solutions, please visit the Industrial Tomography Systems (ITS) website: https://www.itoms.com/ or contact the team at: sales.support@itoms.com.