For level detection there is a wide range of point level sensors operating on different technologies: vibrating level switches (vibrating forks), capacitive point level sensors, sensors with frequency deviation, floating switches or optical sensors. Point level sensor requirements differ with the application and the factors to be considered: foam, aggressive or inflammable media, adhesion and build-up, difficult installation conditions, dynamic filling processes, required measuring precision, etc. Conventional vibrating forks are still very common in industrial applications of point level detection. Their operating principle is rather simple: a piezo drive makes the two fork arms vibrate. In air, the fork’s vibration is stronger than in liquids which have a damping effect. Electronics evaluate the change in vibration, and immediately when recognizing the damping effect on the fork there is a switching operation.

In some applications however, vibrating forks are not the ideal choice due to their design and technology. Some of them include large components reaching far into the medium to be detected, reason why they are not appropriate for tight installation space. Viscous media also tend to adhere to the fork arms while coarse-grained media could get caught in between. Both can result in switching errors. Furthermore, these forks are difficult to clean and the media to be detected (fluid, foam, powder, granule) may require individual designs.

Baumer offers an alternative approach for simplified point level monitoring. Point level sensor CleverLevel is the smart solution for applications where standard vibrating forks are still in use. Operating on the technology of frequency deviation perfected by Baumer and in a special sensor design, CleverLevel is free from the mentioned drawbacks of vibrating forks but provides a lot of benefits in practical use:

- Media-independent detection – one sensor for all media

- Resistant to adhesion and foam

- Temperature stability up to process temperatures of 150 °C (ambient temperature up to 85 °C)

- Phase separation via switching outputs

- reduced immersion length for compact machines

- ATEX including Zone 0

- Fast reaction in vacuum containers

Proven point level detection in industrial cleaning units

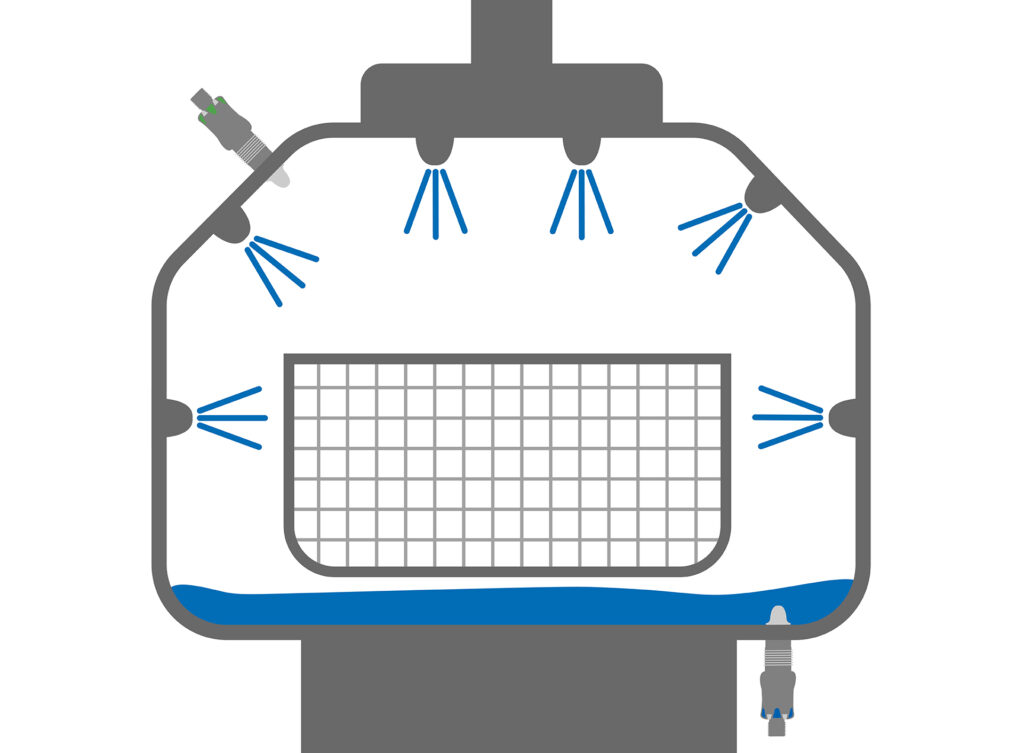

Industrial cleaning units are the preferred application for level detection with CleverLevel. These units degrease, clean and preserve workpieces and components made of metal, plastic, glass or ceramic at different stages of the production process. Particles and contaminating films are removed to make sure the components obtain a defined level of technical cleanliness. Industrial cleaning is common in the automotive industry, mechanical engineering, metal processing and healthcare and primarily used for:

Quality assurance: Residues may lead to malfunction of precision mechanical or electronic components.

Preparing for the downstream process: Many production steps (coating, lacquering, welding) require absolutely clean surfaces.

Corrosion protection: Removing residues like salt or moisture protects against corrosion.

Extended service life: Clean surfaces reduce wear, particularly at moving parts.

When it comes to resource consumption, the requirements for industrial cleaning units are similar to those for the process industry. For enhanced sustainability and resource efficiency, as little energy, water and chemicals as possible should be consumed. The cleaning quality should also be monitored inline using sensors.Cleaning becomes an ever greater integer part in the manufacturing process, for example automated inline cleaning solutions. Another factor is miniaturization of the components to be cleaned. In production processes, even very small or sensitive parts like used in medical or micro technology must meet the highest standards of cleanliness.

Application example ATEX

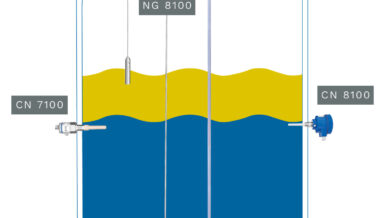

The following example is a typical requirement profile for point level detection in inline cleaning units. One customer required reliable min-max level monitoring of the washing unit where the sensor head is exposed to process temperatures between 100 °C and 150 °C. Ambient temperature at sensor housing can reach up to 85 °C. The required point level sensor had to resist cleaning agents and was expected to automatically recognize different media in cleaning stages: solvents and agents, oil, fresh and waste water as well as solids.

Further requirements were explosion protection (ATEX and IECEx up to and including Zone 0) and a compact design. The insulated cleaning unit to save energy provided only little space for a sensor, let alone vibrating forks.

The Baumer CleverLevel is up to each of these requirements and convinced with additional benefits: It allows for phase separation via switching output (alcohol/solvent/water) and, unlike vibrating forks, is fast reacting in vacuum containers. This ensures safe, reliable and efficient point level detection in the cleaning process.

Conclusion

Easy point level monitoring with the technology of frequency deviation perfected by Baumer in CleverLevel, has decisive benefits. Most, CleverLevel featuring automatic media recognition without need for parameterization will ease work enormously. whether bulk material, powder, fluid, foam, sticky, viscous or watery media. CleverLevel will detect cleaning agents just as easily as industrial sludge. More typical applications are overfill protection or selective detection suppressing foam or separating layers. Space-saving CleverLevel will masters all these tasks by a single, user-friendly sensor technology.

CleverLevel: Features and commissioning

What is the principle of the technology of frequency deviation utilized by CleverLevel? Every medium, no matter of its consistency, has a specific dielectric strength. Therefore, in the electrical field built by CleverLevel, the medium’s behavior at a certain temperature will always be the same. This is utilized by the technology of frequency deviation. Depending on the measured resonance frequency, the sensor recognizes whether it is immersed in a fluid, a solid medium or in gas. This is the reason why CleverLevel is capable of ignoring adhesion or foam at the sensor head. High sensitivity throughout a wide dielectric range from constant 1.5 to more than 100 allows for point level detection in all types of powders, granules and fluids.

Commissioning is easy. Even with default parameterization most media are reliably recognized. When in doubt, use the teach-in function. More complex parameterization tasks are simplified with the intuitive software Baumer Sensor Suite allowing the user to see what the sensor is seeing. The switching window can be adapted to the requirements, e.g. hiding foam for maximum and minimum point level detection. The same applies to adhesion at the sensor head which is ignored. Electrostatic adherence often present in powdery media is also ignored by parameterization of a corresponding switching window.

Learn more about Baumer CleverLevel: www.baumer.com/c/13561