Global meat consumption has risen fivefold since the 1960s2, and the OECD (Organisation for Economic Co-operation and Development) predicts that, ‘Total growth in meat consumption is projected at 47.9 Mt over the next decade.’ Over the same period, per capita consumption is projected to increase by 0.9 kg per capita/year1. Poultry is the most consumed meat globally, followed by pork and then beef and veal3. However, regional changes in consumption are changing global trade patterns and markets. The OECD adds that, ‘In high-income countries, consumers are increasingly sensitive to animal welfare, environmental and health concerns, leading in some instances, per capita meat consumption to stagnate.’ Likewise, ‘By 2034, China’s share of global meat imports is set to decline from 20% in the base period to 16%.’

Together these factors mean that global meat processors could face increasing uncertainty in the near future, underlying the need for investment decisions to maximise business efficiency and flexibility.

Technical challenges of meat and co-products

Meat and poultry processing operations have always produced a range of co-products and leftover materials, many of which have traditionally been turned into meat, blood and bone meal commodity products for use in animal feed or fertiliser. However, new technologies and a growing population means there is increasing demand for co-products and skimmings, including poultry trimmings, bone, blood and blood plasma, fats and oils, gelatine, mechanically deboned meat (MDM) and other edible protein components.

To maximise the usefulness and value of such materials, it is important that processing equipment produces high quality products at low cost, with little waste and minimal energy consumption. Something which is equally true for primary products such as meat slurry and mechanically deboned meat derivatives. Heat exchangers are frequently used for a range of purposes, including heating, cooling, pasteurisation, sterilisation and even evaporation. Meat and meat-derived materials have a high fouling potential (which limits heat transfer) but also need delicate handling to preserve their quality.

Their highly viscous nature also means that a phenomenon can occur where two distinct areas of temperature appear in the product. For example, if cooling using a double tube heat exchanger (with the product in the inner tube and the service fluid on the outside), then – if the product does not thoroughly mix as it passes through – a ‘cylinder’ of warmer product may travel down the centre of the tube while the product nearest the outside of the tube becomes increasing cold. Where product needs to be held at a low temperature (for example below 4 °C) and a low temperature cooling medium is utilised, this can result in product at the tube wall freezing, while the material in the centre is not cooled sufficiently. The same phenomenon can also occur in reverse when heating a chilled product.

Scraped surface heat exchangers

To overcome this, an annular space heat exchanger (such as the HRS AS 3 Series) where the service fluid passes down the centre and around the product at the same time, may be considered instead of a double tube heat exchanger (like the HRS DTA Series). However, the AS Series is not suitable for products containing particles or pieces. This means that scraped surface heat exchangers are often the most suitable option when handling meat products.

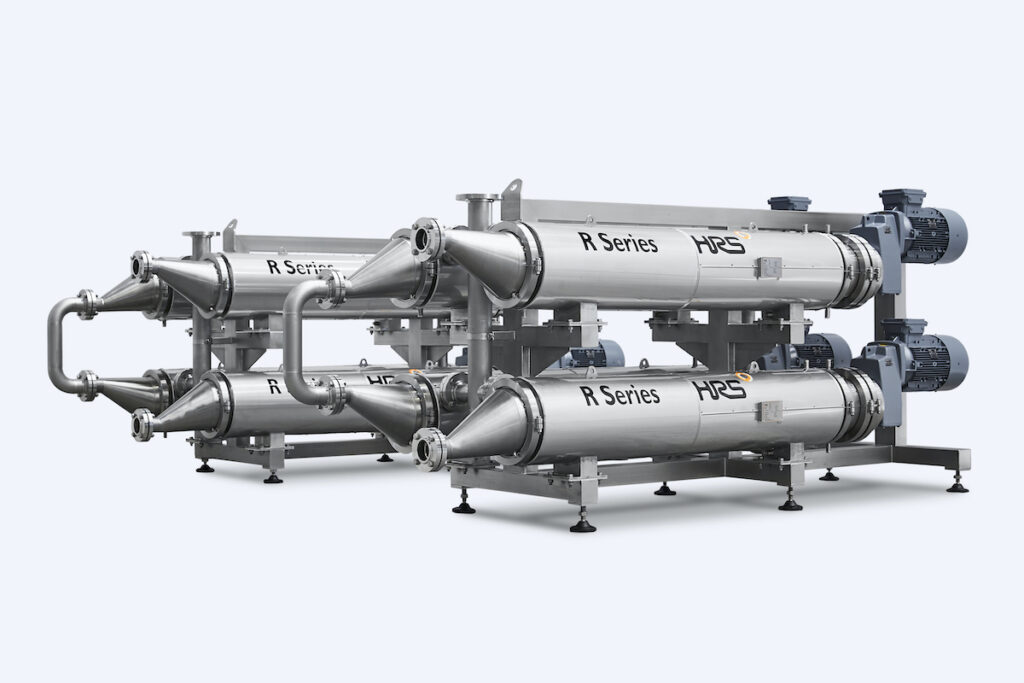

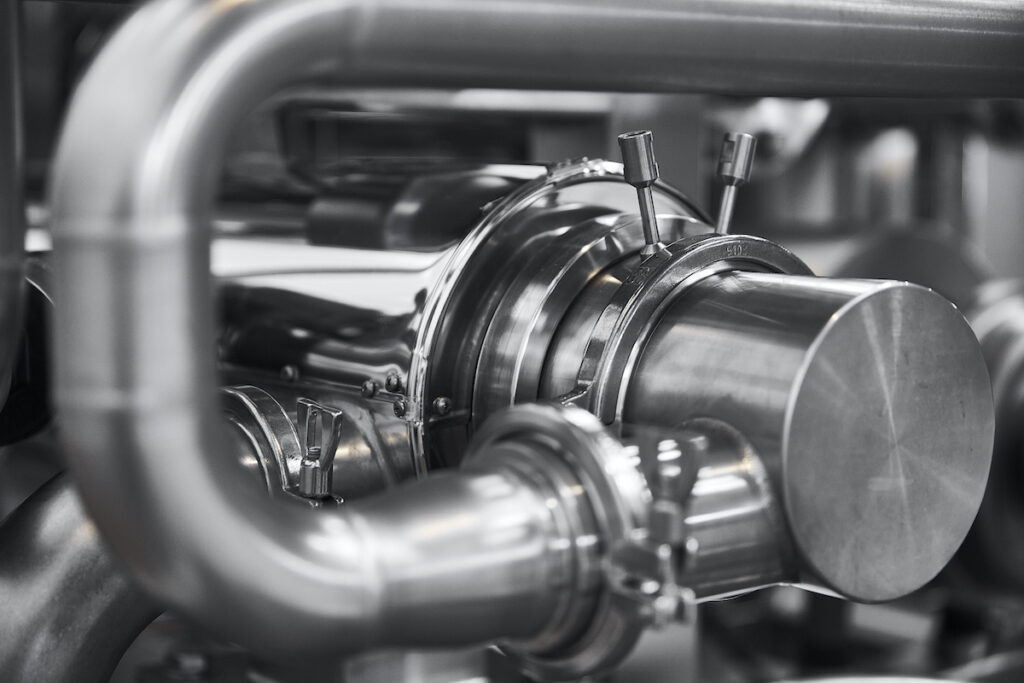

It is important to choose a heat exchanger that combines gentle handling of the product with thorough mixing (to prevent the phenomenon described above). Heat exchangers for meat and meat co-products also need to be robust enough to withstand heavy duty use, which is why HRS Heat Exchangers developed the RHD Series of rotary scraped surface heat exchangers with an adapted internal scraper configuration and heavy-duty gearbox to withstand the higher torque required to keep such products moving, particularly at very low temperatures.

The high velocity scrapers of the RHD Series and R Series help increase heat transfer, resulting in a heat exchanger with a smaller surface area, lower working pressures, smaller footprint, and lower capex compared with other designs. The scraper bar and helical screw within the tube of the R Series can also be configured (depending on installation type) to run in reverse, effectively emptying the heat exchanger tubes of product without damaging it or changing its characteristics, helping to minimise product losses from cleaning-in-place (CIP), product change overs, etc.

In other situations, and for other meat products, a reciprocating scraped surface heat exchanger, such as the HRS Unicus Series, may be more suitable. The Unicus Series is ideal for a wide range of difficult meat products and meat waste streams and is available with a wide range of scraper types, providing even more choice for applications from cooling to sterilizing and everything in between.

The HRS Unicus Series is particularly useful for handling viscous food products where texture and consistency are important attributes. For example, some meat mixtures may shear or break apart when subjected to too much pressure and speed, making them unusable. The Unicus means that effective heat transfer can be carried out at low pressure overcoming such problems. Some of the practical uses of the Unicus Series include cooling chicken viscera and pet food ingredients, cooling MDM and heating or cooling blood.