Ecogas built New Zealand’s first full scale energy plant powered by food waste at Reporoa, in the middle of the North Island. The plant processes around 75,000 tonnes of organic waste each year from council kerbside collections, commercial and industrial food producers – eliminating more than 11,000 tonnes of CO2 a year and helping towards New Zealand’s target of being net carbon zero by 2050.

Commenting on the award, CEO of Ecogas and Pioneer Energy Group, Peter McClean, said the success has only been possible through strong partnerships and a shared vision to divert organic waste from landfill and create lasting value for New Zealand. “We championed this technology in a highly competitive market with limited policy mandates or financial incentives. We are incredibly grateful to our partners, councils, and commercial customers who have supported us on this journey,” he explained.

The plant, which was officially opened in October 2022, produces biogas and digestate biofertiliser, with the biogas upgraded into biomethane for injection into New Zealand’s gas grid, and the carbon dioxide is supplied to a nearby tomato greenhouse where it helps crop growth.

The co-mingled food waste used as feedstock at Reporoa has the potential to contain organisms which have the potential to impact human, animal, or plant health. The HRS Digestate Pasteurisation System (DPS) pasteurises the digestate produced at the plant prior to use to render such pathogens inert, along with other undesirable elements such as weed seeds. This means that the valuable and sustainable biofertiliser can be safely used by farmers and growers.

Traditional pasteurisation systems heat the digestate in a tank using a heating jacket – a bit like waiting for a giant kettle to boil – and then dump the heat after it has served its original purpose. The HRS system, however, employs energy recovery and is typically two to three times more efficient. By transferring energy from the hotter (pasteurised) sludge to the colder (unpasteurised) sludge, energy consumption is reduced, and the need for additional heat sources is removed.

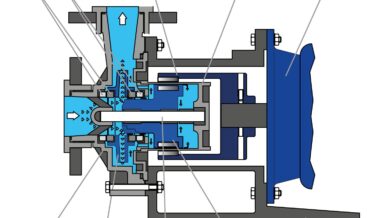

The HRS DPS utilises ‘waste heat’ from the site based Combined Heat and Power Plants (CHP) to heat digestate to >70 °C and hold it for one hour at this temperature, before cooling. This is done with the HRS DTI Series heat exchangers, which are designed in such a way to recover up to 70% of the heat energy required for the process. The tube which carries the digestate through the system’s heat exchanger features a unique corrugated design; unlike the smooth or dimpled tubes used in alternative exchangers. This boosts heat transfer by creating extra turbulence and helps reduce fouling, resulting in less downtime and maintenance, and increasing the system’s lifespan.

The fully automated system provides an auditable kill-step for efficient and effective reduction of pathogens such as Salmonella, Staphylococcus, E. coli etc. Once treated in this way, the digestate produced is safe biofertiliser product, turning what would otherwise be a waste stream into a value-added organic substitute to mineral fertilisers. Not only does the DPS heat-treat the digestate, but it also helps to remove odours while maintaining the quality of the resulting biofertiliser.

The DPS was delivered to site and installed in February 2022. The heat exchanger section of the HRS DPS is split into two frame modules, which are stacked and inter-connected for reduced footprint on site.

Alzbeta Bouskova, General Manager at Ecogas explained why the company chose to use the HRS DPS system. “Ecogas adopted UK-based PAS110 digestate standards as our primary design and operation principle to ensure that the biofertiliser produced from the Reporoa facility is of the highest quality, safety and value for the potential users. Pasteurisation is a key step in the PAS110 standard for source-separate food waste for destroying pathogens and viruses potentially present in this type of waste.

“The Reporoa plant is the first of its kind in New Zealand, and with that comes the process of introducing our new biofertiliser product, Fertify™, to the farming and horticulture sector. We know that brand trust is hard to earn but easy to lose with the community and we have no room for mistakes. We chose HRS based on their reputation and strong track record in digestate pasteurisation. This was further supported by the highly engaged local HRS team, who worked hard to meet their timelines and quality of the equipment and installation.”

Ella Taghavi, Sales Engineering Manager at HRS Heat Exchangers, added, “It is fantastic to have extended our global footprint for HRS Digestate Pasteurisation Solutions to New Zealand, particularly as Ecogas Reporoa is such a significant project in the development of NZ’s Bioenergy Sector. We firmly believe that if renewable energy from Biogas and Anaerobic Digestion is to reach its full potential globally, then it needs to be as efficient as possible, and that includes extracting the most benefit from digestate in terms of its use as a renewable organic fertiliser.

“We foresee a step-change in the value of this abundant and nutrient-rich by-product, which, with the ever-increasing cost of chemical fertilisers, may very well end up being a key commercial driver for AD Projects in future. The HRS DPS ensures that digestate can be put to good use with the full confidence of the client and the consumer, returning nutrients to the land from where they originated.”