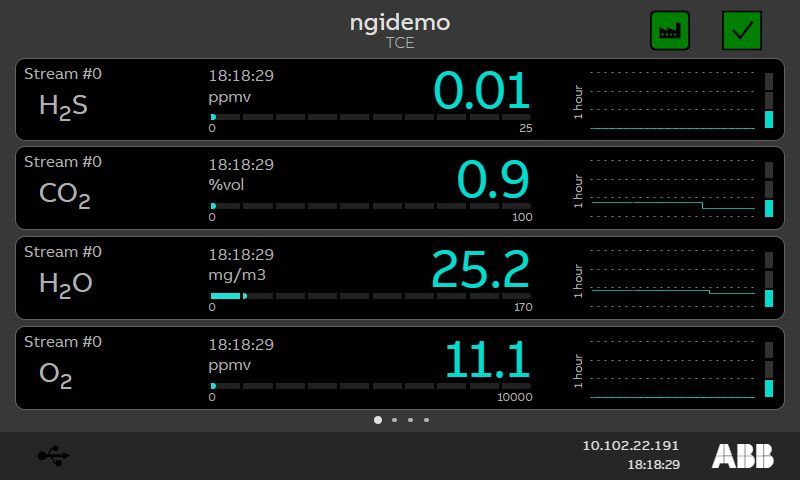

- The next-generation Sensi+ NG measures oxygen (O₂) in natural gas and biogas alongside hydrogen sulfide (H₂S), water vapor (H₂O) and carbon dioxide (CO₂)

- Measuring the four most critical gas contaminants in a single analyzer replaces the need for multiple devices

- Sensi+ NG supports natural gas and biogas producers as well as upstream and midstream pipeline operators with real-time gas quality monitoring

Natural gas contaminants are a significant challenge to an operator’s business as they represent both a safety and pipeline integrity risk due to corrosion. Sensi+ NG ensures that before biogas or biomethane is injected into the gas grid, gas quality meets strict pipeline standards, allowing for safe and reliable transmission.

ABB developed and deployed the original multi-gas contaminant analyzer as a collaborative project with a North American natural gas pipeline leader.

“The original solution was already a revolution in the market with its multi-gas analysis ability, ease of installation, operation and maintenance as well as its reduced footprint and cost of operation,” said Stefan Parmentier, Global Product Manager, Industrial ICOS at ABB’s Measurement & Analytics division. “The enhanced Sensi+ NG is a rugged and intelligent device that builds on that legacy by continuously monitoring the four most critical gas contaminants, ensuring product flow and protecting the safety of assets, environment and people.”

Powered by ABB’s innovative OA-ICOS™ laser technology, Sensi+ NG delivers nearly instant insights and monitoring of natural gas and biogas streams. It also builds on the technology’s capability to allow for the installation of a single analyzer for multiple applications.

Reliable gas readings and fast response time

By consolidating multiple measurements into one smart device, Sensi+ NG maximizes efficiency and performance while improving operational continuity.

Adding O₂ to the mix further enhances process optimization, supporting operators with early problem detection with no missed “upset” events, no false calls or shut-ins, while maintaining regulatory compliance.

Sensi+ NG simplifies operations as a 4-in-1 analyzer by eliminating the need for consumables, frequent calibration or complex maintenance, also reducing the number of devices required. Together, these improvements help minimize product waste and maximize uptime to ensure facility safety and productivity.

There is little to no chance of cross-interference and minimum long-term drift, meaning Sensi+ NG delivers confidence across operations and applications. Its low-maintenance design is particularly advantageous for biogas facilities in remote or rural locations, where operational simplicity and durability are essential.