To date, ITS’s electrical tomography systems have provided the dairy industry with unparalleled real-time imaging and insights into precisely what is happening inside the walls of a pipe or vessel; as milk (or its constituents) are processed to achieve a value-added manufactured dairy product – along with a raft of research applications.

As noted in a recent dairy science publication:

“Electrical resistance tomography (ERT)has recently gained attention for its low-cost, non-invasive, and real-time monitoring capabilities. Electrical resistance tomography offers both qualitative tomographic imaging and quantitative conductivity data.”

The range and versatility of electrical tomography in the dairy manufacturing sector is, seemingly, limitless. To date, ITS technology has been used to measure and monitor:

- fat content in milk

- protein content in whey powder

- casein content during renneting

- whey concentration during the curdling or cheese-making process

- monitoring fruit yogurt mixing to ensure a homogenous mixture

This very brief list of examples is by no means exhaustive and is only a brief snap shot of electrical tomography’s past and present utility – not to mention providing a mere hint at its unlimited potential for the dairy food industry in the future.

ERT is now a proven technology in cheese production; able to provide cheese makers with instant feedback to overcome the challenges associated with seasonal variations in milk composition, yet still be able achieve consistent cheese quality through a smarter production process. Not only does this promote congruous cheese quality, it also results in a reduction of production costs through greater efficiency. The days of cheese makers having to make ‘guesstimates’, or raising a “wet finger in the air”, are now a thing of the past.

ERT’s “qualitative” and “quantitative” abilities have now taken a quantum leap forward with the launch of the T4R, a new high-speed data acquisition system from Industrial Tomography Systems (ITS).

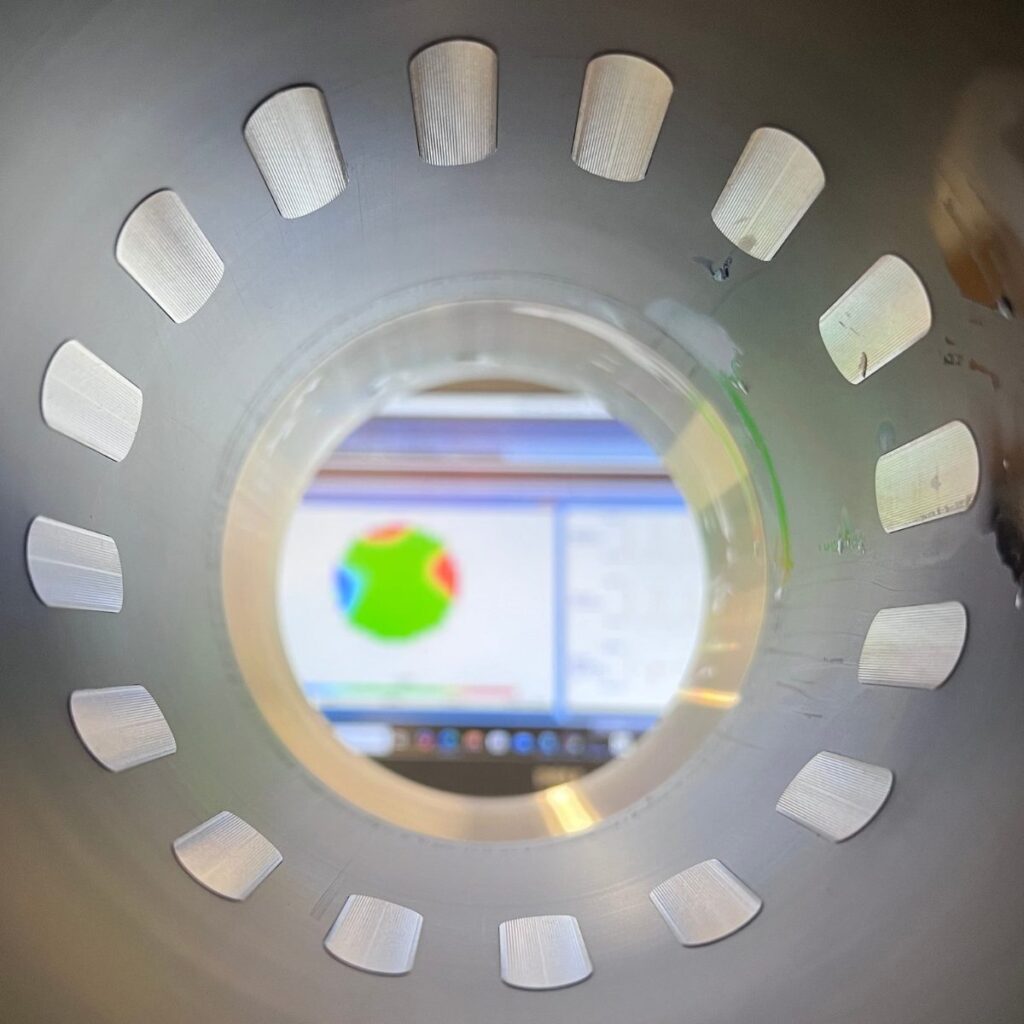

The T4R is an industry-ready “plug and play” data acquisition system, specially designed with the busy dairy production professional in mind. Building on ITS’s established track record providing monitoring systems for dairy research institutions and manufacturing plants, the T4R is a giant leap forward in terms of speed and efficiency with data acquisition speeds of 600 FPS.

Small and compact, the T4R is easy to install and operate through its self-calibrating system software, accompanied by a user-friendly intuitive modular interface that projects both a 2-dimensional dynamic real-time cross-sectional process image alongside Cartesian representations of essential relevant data.

While the T4R is an “off the shelf” system, it integrates seamlessly with ITS’s wide range of inline sensor options manufactured to fit in any part of a dairy production line. Furthermore, both the T4R and its sensors are manufactured to the highest hygiene standards and are fully compliant with all relevant hygiene regulations.

So, if you are feeling “cheesed-off” about your operating expenses, or feel that your dairy manufacturing process has lost its “whey”, the ITS T4R data acquisition system is a simple cost-effective solution to maximise operational efficiency at a minimal cost.

Reduced OPEX for minimal CAPEX; it doesn’t get better than that.

To learn more about the T4R, and our other dairy applications, please contact the team at: sales.support@itoms.com or visit our website https://www.itoms.com/.