Researchers in the oil and gas industry have now added leak detection to the ever growing list of applications for ITS’s technology. A recent paper demonstrated how electrical resistance tomography (ERT) can be used to detect leaks in pipelines carrying multiphase flows; as commonly found in water management, oil and gas, and petrochemical industries. This is an especially important study for industries that use offshore pipelines where the spectre of environmental damage from pipe leakage is always a concern.

As the paper linked here states:

“Early leak detection is one of the most important problems in multiphase flow pipeline systems. In addition to the considerable financial losses they generate, pipeline leakages present serious safety and environmental risks. Therefore, risk mitigation, downtime reduction, and safety regulation compliance all heavily depend on effective leak detection techniques.”

ERT was clearly shown to have a number of advantages over other leak detection technologies currently being used in industry and was proven to be both cost effective while also leading to a maximal reduction in operating expenses and in mitigating risk.

Every business enterprise and industry needs to arrive at a specific solution to the omnipresent CAPEX vs OPEX equation. Once more, ERT has proven to be a highly accurate, cost-effective, and instantaneous monitoring solution whose repertoire of applications has now been extended to include leak detection.

While this is an exciting development, it is important to remind ourselves about electrical tomography’s existing functionalities especially with regard to level measurement in the oil and gas industry and take the opportunity to catch up some recent research.

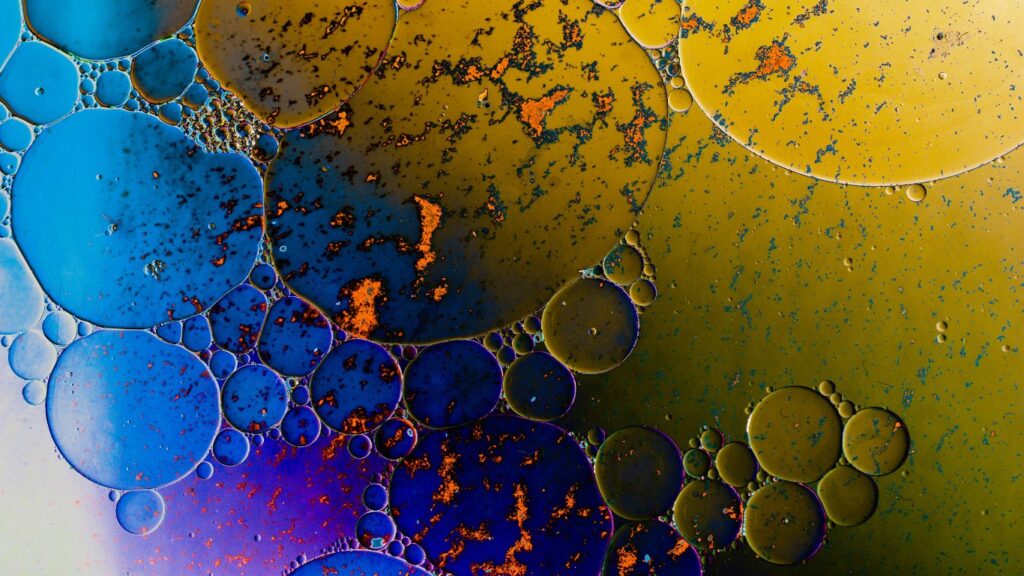

As oil and gas industry professionals will be well aware, multiphase flows consisting of oil, water, and gas are ubiquitous. While there are many technologies adept at measuring level in terms of the gestalt, very few technologies are able to measure the level of each constituent component: electrical tomography is the exception.

While the constituents of a multi-phase flow have different electrical properties with regard to resistance or capacitance, ITS is able to provide a dual modality electrical tomography system that uses both electrical resistance tomography (ERT) and electrical capacitance tomography (ECT) combined into one system.

This approach was discussed as far back as 2018 in a paper delivered at the Institute of Electrical and Electronics Engineers (IEEE) International Conference on Imaging Systems and Techniques (IST) in Krakow Poland.

The paper discussed how a dual modality, ERT and ECT, system can be used to monitor the individual components of a tripartite multiphase flow or emulsion. Electrical tomography has the obvious advantage of being able to provide both empirical data and tomographic images, real time instantaneous “image reconstruction to improve the accuracy of level detection.”

Two other more recent studies have applied ERT as a single modality or combined with an electromagnetic flow meter to monitor multiphase flows or oil and gas reservoirs respectively. Both papers [linked here: 1 and 2] showed good results while being unanimous in their praise of ERT’s non-invasive qualities and cost-effectiveness.

Just as ERT has been studied as a single modality system, a forthcoming paper has studied ECT in a similar way, while also proffering a new solution to improve the quality of the resulting tomograms.

The findings and conclusions of the papers cited above are all easy applications to upscale to either a pilot plant or full-scale industry. Industrial Tomography Systems (ITS) welcomes enquiries from industry professionals about potential applications for electrical tomography in the oil and gas industry.