With peristaltic pumps, the challenge is that tubing properties change over time, which can make it difficult to maintain a precise ratio.

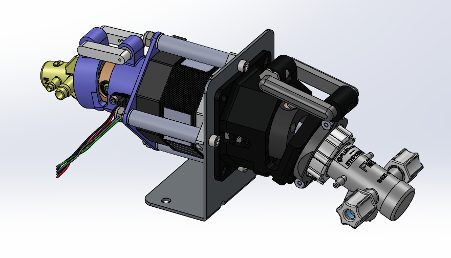

By contrast, rotary piston pumps offer far greater long-term stability. Thanks to their precisely matched ceramic pistons, they can achieve a coefficient of variation (CV) of 0.5% or better, consistently maintained over 100 million of cycles. This makes them ideal for precision dispensing, complex fluid mixing and reconstitution.

Duplex Pump Technology

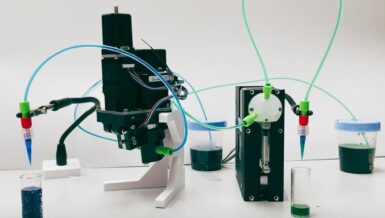

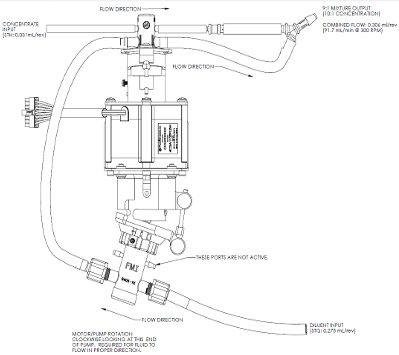

A Duplex Pump features two valveless piston pump heads directly coupled to a single stepper motor drive. Each pump head’s displacement can be independently adjusted, and different pump head sizes can be paired to achieve mixing ratios ranging from 1:1 up to 100:1, from microlitres to litres.

Because both pump heads are mechanically coupled, they are always in phase. This eliminates the challenge of synchronising two separate pumps and simplifies control.

Advantages of Duplex Pumps

- Simplification – Only one motor and controller are required, reducing electrical and system complexity.

- Space Saving – Two pump heads on one drive free up valuable space in your lab or instrument.

- Cost Efficiency – A single duplex pump is typically less expensive than two independent pumps, while also reducing maintenance.

- High Precision Mixing – Capable of reconstituting highly concentrated fluids with extreme accuracy.

Fluid Metering, Inc. offers a range of Duplex pump options — from stepper-based systems to the QB series with dual shaft or dual head configurations.

Summary

- Single stepper motor drive

- Only one controller required

- Mixing ratios up to 100:1

- Designed for complex fluid mixing and reconstitution

- One pump head can be used to flush the other, reducing system complexity