Pump Technology Comparison Table

| Pump Type | Fluid Metering Valveless Piston | Peristaltic | Diaphragm | Centrifugal | Gear |

| Flow Accuracy | 0.5–1% CV | 5–10% CV | 3–7% CV | Poor at low flow | 2–5% CV |

| Pressure Capability | Up to 200 PSIG | Low (<30 PSIG) | Moderate (50–100 PSIG) | Low | High (100–200+ PSIG) |

| Self-Priming | Yes | Yes | Yes | No | Yes |

| Shear Sensitivity | Low | Low | Low | High | High |

| Pulsation | Moderate to High | Moderate | High | None | Low |

| Particulate Shedding | None (ceramic) | Tubing wear risk | Elastomer wear risk | None | Yes (metal contact) |

| Chemical Compatibility | Excellent (ceramic heads) | Tubing-dependent | Diaphragm material-dependent | Limited | Lubrication/fluid limits |

| Maintenance | Low (long life head) | High (tubing wear) | Moderate | Low | Moderate (wear over time) |

| Cleanability | Autoclavable/Replaceable heads | Disposable tubing | Clean-in-place | Flushable | Flushable |

| Best Use Cases | High Precision metering & dispensing | Single use / disposable | Low precision metering | High flow, low precision | Viscous fluids, dosing |

Technology Overviews

Fluid Metering Valveless Rotating, Reciprocating Piston Pump:

- Uses ceramic wetted components ideal for chemically aggressive or shear-sensitive fluids.

- Combines the precision of a syringe pump with continuous rotary motion.

- Excellent for metering small volumes with low pulsation and minimal maintenance.

Peristaltic Pump:

- Limited pressure and accuracy, especially at low flow rates.

- Uses rotating rollers to compress flexible tubing.

- Easy to sterilize and self-priming, but tubing fatigue leads to drift and replacement.

Diaphragm Pump:

- Uses oscillating membranes to displace fluid.

- Good for metering, but pulsatile.

- Material selection critical for chemical resistance.

- Can be sensitive to particulates.

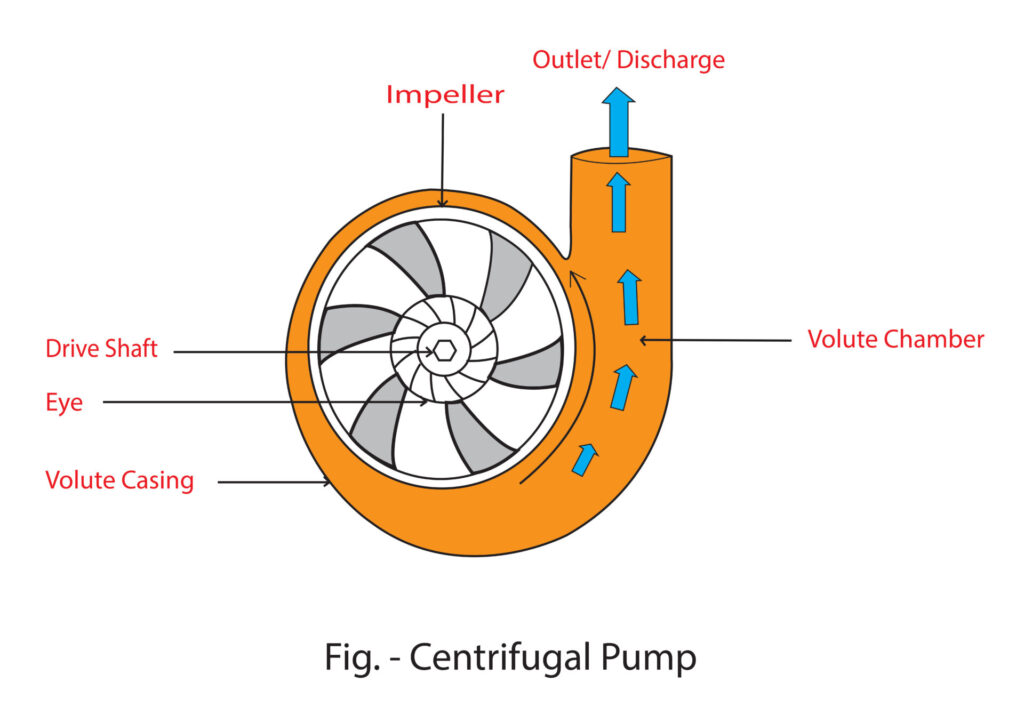

Centrifugal Pump:

- Relies on impellers to generate flow.

- Excellent for high-volume, low-pressure applications.

- Poor at low flow and not precise.

- Not ideal for metering or variable pressure environments.

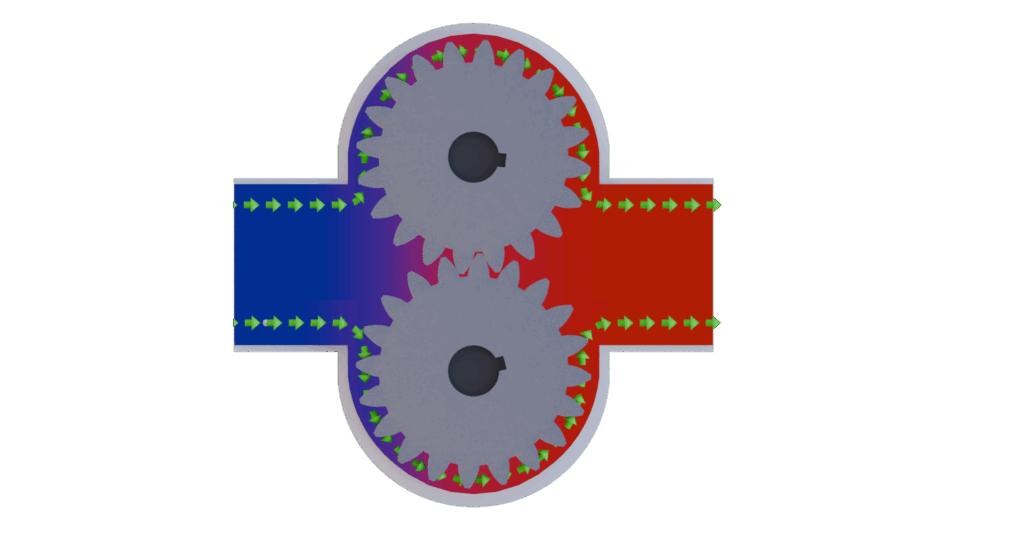

Gear Pump:

- Uses intermeshing gears to move fluid.

- Good for continuous flow of viscous liquids.

- Can shed particulates due to wear.

- Moderate/high accuracy, but not suited for sterile or shear-sensitive applications.

Conclusion

Choosing the optimal pump technology depends on the application’s precision, cleanliness, chemical compatibility, and maintenance requirements. While peristaltic, diaphragm, centrifugal, and gear pumps each have their place, Fluid Metering’s valveless ceramic piston pump stands out for high-accuracy, low-shear metering across a wide pressure range with minimal maintenance. Its ability to deliver consistent flow, combined with excellent chemical resistance and cleanability, makes it a superior choice for demanding pharmaceutical, biotech, and diagnostic applications where performance and reliability are non-negotiable.